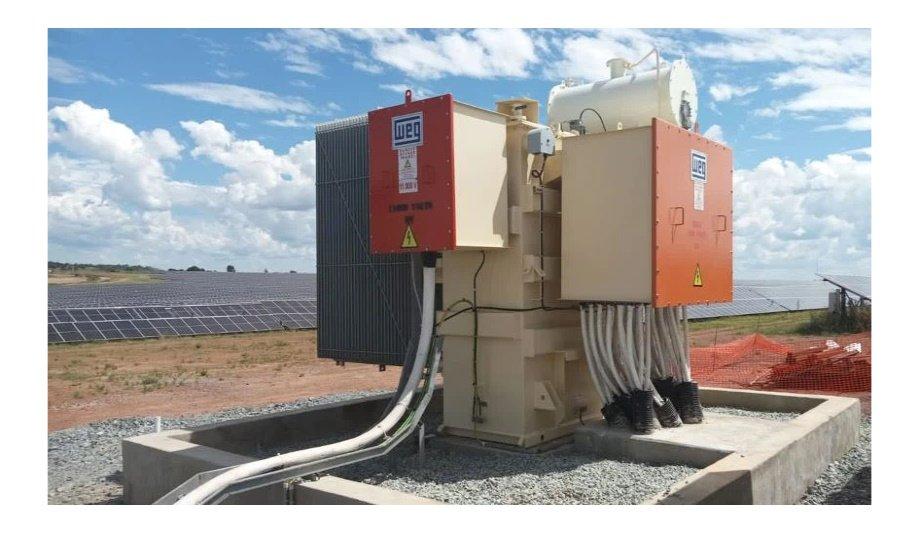

A solar power generating facility recently developed by a South African gold mine has made use of WEG’s transformers to serve this specialized application. Factors like harmonics or ‘noise’ in the current flow mean that solar photovoltaic (PV) applications require specialized transformers.

The site is generating 40 MW of renewable energy and WEG supplied 10 of its custom-designed transformers of 5 MVA capacity each. The units for this PV project were manufactured at the company’s Wadeville factory, in South Africa.

Another innovation in PV project

WEG’s transformers will step up from 690 V current to 11 kV

In this application, WEG’s transformers will step up from 690 V current to 11 kV. The equipment counts on a dual input, single output configuration, allowing one transformer to be fed by a number of string inverters through the dual input.

Another innovation of the recent PV project was the use of ester oil–rather than normal oil from hydrocarbons–as a coolant in the transformers.

Temperature of the transformer windings

From an environmental point of view, ester oil does not carry the risk of contaminating land or water if it happens to leak from the transformer, being a more sustainable option. Operationally speaking, it is also able to withstand higher temperatures without degrading.

It has the advantage of not being flammable, so it would not contribute to an explosion or fire. Ester oil also retains heat better, moderating the temperature of the transformer windings while not activated.