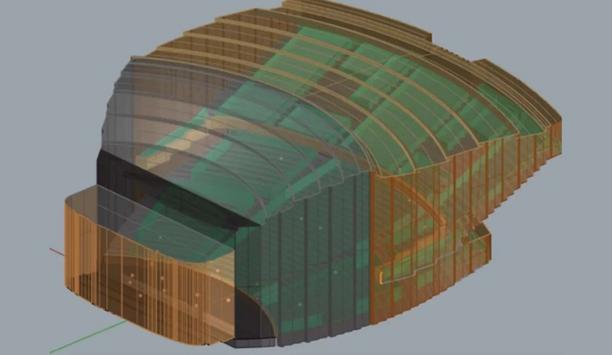

Building Information Modeling (BIM)

Berkshire-based mechanical and electrical engineering firm, Campbell West, has completed a major transformation at Hertfordshire University in Hatfield. The five-month project formed part of a wider renovation project by Carmelcrest at the University’s School of Creative Arts. The works included a complete overhaul of the building’s heating, ventilation, and air-conditioning (HVAC) infrastructure, as well as the refurbishment of the male, female, and disabled WC facilities...

In the ever-evolving landscape of electrical services, the journey towards condition monitoring represents a significant leap forward. Now, customers face challenges, such as aging workforce and infrastructure, rising cost of energy and operation, and lack of transparency to the condition of key building systems. Dealing with these challenges will require a transformation driven by the need for enhanced reliability, efficiency, and safety in electrical distribution systems, with increased autom...

FPT Industrial, the Iveco Group brand dedicated to the design, production, and sale of powertrains and solutions for on- and off-road vehicles, as well as marine and power generation applications, will be heading to Dubai to exhibit at Middle East Energy, one of the most reputable and long-established events in the energy industry, being held from April 7 to 9. The brand will be present alongside its distributor network at Booth S2.C40, showcasing a selection of its offerings for the power gene...

Delta, a global pioneer in power management and smart green solutions, highlighted at Hannover Messe 2025 a versatile set of AI-driven smart manufacturing, energy infrastructure, and data centre solutions. These include, the award-winning D-Bot series cobots, featuring advanced cognitive capabilities and integration with NVIDIA Omniverse to develop next-generation digital twins; and DeltaGrid®, the AI-enabled energy management platform to optimize efficiency in the energy infrastructure sup...

On June 7, 2021, the generator terminal subsynchronous damping control (GTSDC) system of Datang Xilinhaote (Xilinhot) power plant completed the oscillation suppression test and put into operation successfully. NR worked as the total solution provider for this project. The successful operation of the system enhances the damping performance of the complex resonance between the generator and the grid, and can effectively solve the torsional vibration problem of the turbine generator shaft system u...

On June 3, the Huzhou distributed power flow controller (DPFC) pilot project, developed and supplied by NR, successfully withstood the manual short circuit test. The system responded accurately and the test results met the expectations. The success of this manual short-circuit test fully verified the ability of NR DPFC ability to withstand AC short-circuit current, AC fault ride through ability, and the accuracy of cooperation with AC line protection, marking that the 220 kV DPFC project has al...

News

Smartkem, which is seeking to change the world of electronics with a new class of transistor technology, announced that now, Friday, March 21, 2025, Chairman and CEO Ian Jenks, CFO Babara Keck, and Head of Communications Selena Kirkwood will ring the opening bell at the Nasdaq MarketSite in Times Square, NYC. Commercialization of microLED Jenks stated, "We are extremely excited and honored to ring the opening bell to increase awareness of our progress to enable the adoption and mass commercialization of microLED displays. We continue to advance our goal of commercializing our proprietary semiconductor materials, which enable flexible, transparent, and lightweight microLED displays." The Nasdaq opening bell ceremony will be broadcast live at 9:15 a.m. Eastern Time from the Nasdaq MarketSite Tower in New York City, New York.

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, announced the launch of its next-generation DC Wallbox 50kW EV charger. Designed to meet the demands of public and commercial charging applications, the upgraded model delivers advanced functionality and an optimized user-centric experience, ensuring seamless and efficient charging for both operators and electric vehicle (EV) drivers. EV charging infrastructure "The next-generation DC Wallbox 50kW exemplifies Delta's dedication to advancing the EV charging infrastructure with solutions that are both practical and innovative," said Arto Suni, Senior Director Electric Vehicle Charging Solutions, Delta Electronics EMEA. "By integrating payment systems, enhancing usability, and prioritizing safety, we are delivering a new benchmark in quick and convenient public and commercial EV charging." Advanced Functionality Integrated Meter and Payment Terminal: The next-generation DC Wallbox 50kW integrates a certified energy metering system and a credit card terminal for ad-hoc payment. This system enables secure, pre-authorized transactions, simplifying the payment process for EV drivers and ensuring accurate billing. With support for contactless cards, mobile payments, and RFID authentication, the charger ensures a quick and convenient payment experience. Enhanced Charging Status Light: A new charging status light on the front panel provides clear, real-time visual indicators of the charger's status. This intuitive feature enables EV drivers to easily identify available charge points, optimizing the overall user experience. Advanced Cable Management System: Delta's advanced cable management system offers a safe, durable, and user-friendly solution for cable handling. By minimizing clutter, protecting cables from wear and tear, and facilitating easy access, this system enhances safety and convenience, making the charger ideal for commercial EV fleets and public charging stations. Building on Success The next-generation DC Wallbox 50kW retains the key features that made its predecessor a market pioneer, including: High Efficiency: Achieves a 97% energy conversion rate, significantly reducing electricity loss and operational costs. Compact Design: With a slim 25cm profile, it saves up to 60% of installation space compared to conventional chargers, making it suitable for space-constrained locations. Dual Charging Output: Supports simultaneous DC charging through two output guns to accommodate a wide range of EV models and optimize usage turnover. Robust Connectivity: Built-in Ethernet and wireless communication enable efficient remote management and maintenance. The DC Wallbox 50kW underscores Delta's commitment to providing high-performance, space-efficient, and sustainable charging solutions that cater to the growing global demand for electric mobility.

Lanner Electronics, a pioneer in network computing appliances and industrial AI computers, will officially unveil its latest innovation, the EAI-I233 and EAI-I251 industrial-grade Edge AI computers, at NVIDIA GTC 2025. Powered by the NVIDIA® Jetson AGX Orin™ system on module (SOM), these advanced platforms are designed to deliver low-latency AI inferencing capabilities at the edge for industries including retail, manufacturing, transportation, and smart city. EAI-I233: AI inference system The EAI-I233 features a compact design and is powered by the NVIDIA Jetson AGX Orin SOM The EAI-I233 features a compact design and is powered by the NVIDIA Jetson AGX Orin SOM, offering up to 64GB LPDDR5 memory and 2048 CUDA® cores for exceptional AI performance. With versatile connectivity options, including 1x GbE RJ45, 1x 10GbE RJ45, 1x 2.5GbE RJ45, 4x USB 3.2, 2x COM, and M.2 expansion slots for WiFi and 5G/LTE connectivity, this platform is ideal for deployment in space-constrained environments, such as retail stores, airports, branch offices, enabling real-time AI inferencing for video analytics applications. EAI-I251: Ruggedized AI Platform for Extreme Conditions The EAI-I251, designed for harsh environments with an operational range of -40°C to 70°C, is powered by the NVIDIA Jetson AGX Orin SOM with 64GB LPDDR5 memory. Ideal for AI inference in autonomous systems, industrial visual inspection, and physical security, it features extensive I/O options, including 8x video-in (GMSL2), multiple LAN ports (1GbE, 10GbE, 2.5GbE with PoE+), USB 3.2, COM (optional CAN), DIO and M.2 slots for WiFi and 5G/LTE connectivity. This compact yet robust solution ensures seamless integration for edge AI applications. NVIDIA JetPack SDK 6.2 Support NVIDIA Metropolis stack for vision AI workloads, CUDA-X™ accelerated libraries, and robust development tools Seamlessly integrated with the NVIDIA JetPack™ SDK 6.2, both EAI-I251 and I233 empower developers with access to Jetson™ Linux, NVIDIA Metropolis stack for vision AI workloads, CUDA-X™ accelerated libraries, and robust development tools, accelerating the deployment of AI-driven in-vehicle video analytics. “With the NVIDIA Jetson platform, our latest edge AI computers redefine industrial AI performance, reliability, and connectivity,” said Spencer Chou, Senior Director of the Edge AI Division at Lanner Electronics. Advancements in AI and edge computing Chou added: “Introducing these innovations at NVIDIA GTC 2025 underscores our commitment to driving advancements in AI and edge computing for mission-critical applications.” The EAI-I233 and EAI-I251 will debut at Lanner's Booth #1908 during NVIDIA GTC 2025, Mar 17-21, at San Jose Convention Center. Visitors can experience live demonstrations and explore how these platforms enable real-time AI inferencing across industrial sectors.

Luxi Island microgrid system, which was designed, supplied, commissioned and delivered by NR, has been successfully put into operation. The system effectively solved the black start problem of 10kV feeder level microgrid with impulsive load, and has won high recognition from users with an advanced and intelligent control strategy, a stable and reliable microgrid system. Power supply of Luxi Island The power supply of Luxi Island was transmitted remotely by submarine cables Luxi Island is located on the east coast of China. The power supply of Luxi Island was transmitted remotely by submarine cables, which was easy to cause power supply interruption due to cable and tower damage. Due to the weak load carrying capacity of the original microgrid system, complex black start steps, difficult operation and low success rate, once the power was cut off, the recovery time was long, which seriously affects the production and life of residents on the island. Microgrid energy management system NR provides microgrid integrated solutions, including a microgrid energy management system, a microgrid coordination controller, an energy storage converter, and other core equipment, which effectively solves the existing problems. A microgrid system was required to quickly restore power supply after a power loss of the large power grid, and the black start function was the most important means to restore power supply and an important guarantee for the stable operation of the system. 10kV distribution network feeders usually have a large number of T-connected transformers, large load capacity. Research of microgrid technology NR successfully realized the black start function under the condition of full input of 10kV The simultaneous start of transformer inrush current and a large number of motor loads was easy lead to black start failure. The automation level of the existing distribution network system was low, relying on the manual opening and closing switch of the operation and maintenance personnel, and the power failure time of the system was long. In view of these problems, based on the long-term accumulation in the research of microgrid technology, NR successfully realized the black start function under the condition of full input of 10kV feeder load through intelligent one-key black start control and flexible synchronous parallel start technology of multiple converters. Technical advantages of NR The whole process took less than 10s from the issuance of command to the stable establishment of bus voltage, and quickly realized power supply restoration of 18 transformers, 1359 resident users and 177 non-resident users. The power supply reliability of Luxi Island has been significantly improved. The successful implementation of the project has further consolidated the technical advantages of NR in the field of microgrid, and provided the solution for the local autonomy of the new distribution system with high distributed energy resource penetration. NR will continue to practice the corporate purpose of "creating value and serving society", and contribute more to the development of a reliable green power system.

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automation and ICS/SCADA security. Powered by the Intel® Xeon® 6 Processor, the ICS-P770 delivers exceptional compute performance, security acceleration, and high-speed connectivity for power grid applications. Designed to meet the most demanding requirements of modern digital substations, the ICS-P770 supports up to 512GB of DDR5 RDIMM memory and offers high-speed networking with four 2.5GbE RJ45, two GbE SFP, and two 25GbE/10GbE SFP/RJ45 interfaces. Redundant Storage Solutions The system provides multiple PCIe expansion slots, including 4 PCIe Gen5 slots, with support for HSR/PRP PCIe Card, ensuring seamless redundancy in the event of a network failure. Additionally, the industrial computer features four hot-swappable U.2 NVMe storage bays with RAID support, ensuring high-speed data logging and redundancy for critical energy applications. Strength Meets Security Designed to withstand harsh substation environments, the ICS-P770 features an IP30-rated rugged chassis with intelligent fan cooling and is certified for operation in extreme temperatures from -25°C to 55°C. Advanced security measures, including TPM 2.0 and Intel® QuickAssist Technology, ensure robust encryption, authentication, and secure remote access, making it an ideal choice for virtualization and SCADA security. Revolutionizing Substation Tech "Lanner Electronics' ICS-P770 is a game-changer for next-generation digital substations and virtual protection, automation, and control (vPAC). It offers unparalleled performance, availability, and reliability with its Intel® Xeon® 6 Processor (featuring 64 e-Cores), high-speed networking, network redundancy, and robust security features," said Dave Meng, Senior Director of Business Development for Power and Energy at Lanner. "This IEC 61850-3 certified server platform is designed to meet the most demanding requirements for substation virtualization.” Smart grid innovation Lanner invites industry professionals, system integrators, and energy leaders to Booth #5749 at DISTRIBUTECH 2025 for a firsthand look at how the ICS-P770 is transforming substation automation, real time analytics, and critical infrastructure protection.

Tolomatic Inc., an industry pioneer in innovative linear motion systems, will be showcasing its latest servo linear actuators at Automate 2025. Featuring an integrated servo motor, Tolomatic servo linear actuators are ideal for applications where dynamic movement, precise positioning and force repeatability are a priority. Tolomatic products Tolomatic products include the IMA and IMA-S linear servo actuators. These actuators feature integrated servo motors to save space and are available in both ball and roller screw configurations. Their space and weight efficiency benefit compact machine designs, and their durable construction makes them resistant to shocks and vibrations. Ongoing maintenance requirements As servo linear actuators, they reduce commissioning time and ongoing maintenance requirements. The IMA-S is a stainless steel IMA actuator with an IP69K-rated, hygienic design ideal for the most demanding food and beverage applications, including washdowns. Tolomatic will be featuring its servo linear actuator designs at Automate 2025, detailing how they work and exploring their applications, including food, beverage, plastic, and automotive manufacturing.

Smartkem, which is seeking to change the world of electronics with a new class of transistor technology, announced that now, Friday, March 21, 2025, Chairman and CEO Ian Jenks, CFO Babara Keck, and Head of Communications Selena Kirkwood will ring the opening bell at the Nasdaq MarketSite in Times Square, NYC. Commercialization of microLED Jenks stated, "We are extremely excited and honored to ring the opening bell to increase awareness of our progress to enable the adoption and mass commercialization of microLED displays. We continue to advance our goal of commercializing our proprietary semiconductor materials, which enable flexible, transparent, and lightweight microLED displays." The Nasdaq opening bell ceremony will be broadcast live at 9:15 a.m. Eastern Time from the Nasdaq MarketSite Tower in New York City, New York.

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, announced the launch of its next-generation DC Wallbox 50kW EV charger. Designed to meet the demands of public and commercial charging applications, the upgraded model delivers advanced functionality and an optimized user-centric experience, ensuring seamless and efficient charging for both operators and electric vehicle (EV) drivers. EV charging infrastructure "The next-generation DC Wallbox 50kW exemplifies Delta's dedication to advancing the EV charging infrastructure with solutions that are both practical and innovative," said Arto Suni, Senior Director Electric Vehicle Charging Solutions, Delta Electronics EMEA. "By integrating payment systems, enhancing usability, and prioritizing safety, we are delivering a new benchmark in quick and convenient public and commercial EV charging." Advanced Functionality Integrated Meter and Payment Terminal: The next-generation DC Wallbox 50kW integrates a certified energy metering system and a credit card terminal for ad-hoc payment. This system enables secure, pre-authorized transactions, simplifying the payment process for EV drivers and ensuring accurate billing. With support for contactless cards, mobile payments, and RFID authentication, the charger ensures a quick and convenient payment experience. Enhanced Charging Status Light: A new charging status light on the front panel provides clear, real-time visual indicators of the charger's status. This intuitive feature enables EV drivers to easily identify available charge points, optimizing the overall user experience. Advanced Cable Management System: Delta's advanced cable management system offers a safe, durable, and user-friendly solution for cable handling. By minimizing clutter, protecting cables from wear and tear, and facilitating easy access, this system enhances safety and convenience, making the charger ideal for commercial EV fleets and public charging stations. Building on Success The next-generation DC Wallbox 50kW retains the key features that made its predecessor a market pioneer, including: High Efficiency: Achieves a 97% energy conversion rate, significantly reducing electricity loss and operational costs. Compact Design: With a slim 25cm profile, it saves up to 60% of installation space compared to conventional chargers, making it suitable for space-constrained locations. Dual Charging Output: Supports simultaneous DC charging through two output guns to accommodate a wide range of EV models and optimize usage turnover. Robust Connectivity: Built-in Ethernet and wireless communication enable efficient remote management and maintenance. The DC Wallbox 50kW underscores Delta's commitment to providing high-performance, space-efficient, and sustainable charging solutions that cater to the growing global demand for electric mobility.

Lanner Electronics, a pioneer in network computing appliances and industrial AI computers, will officially unveil its latest innovation, the EAI-I233 and EAI-I251 industrial-grade Edge AI computers, at NVIDIA GTC 2025. Powered by the NVIDIA® Jetson AGX Orin™ system on module (SOM), these advanced platforms are designed to deliver low-latency AI inferencing capabilities at the edge for industries including retail, manufacturing, transportation, and smart city. EAI-I233: AI inference system The EAI-I233 features a compact design and is powered by the NVIDIA Jetson AGX Orin SOM The EAI-I233 features a compact design and is powered by the NVIDIA Jetson AGX Orin SOM, offering up to 64GB LPDDR5 memory and 2048 CUDA® cores for exceptional AI performance. With versatile connectivity options, including 1x GbE RJ45, 1x 10GbE RJ45, 1x 2.5GbE RJ45, 4x USB 3.2, 2x COM, and M.2 expansion slots for WiFi and 5G/LTE connectivity, this platform is ideal for deployment in space-constrained environments, such as retail stores, airports, branch offices, enabling real-time AI inferencing for video analytics applications. EAI-I251: Ruggedized AI Platform for Extreme Conditions The EAI-I251, designed for harsh environments with an operational range of -40°C to 70°C, is powered by the NVIDIA Jetson AGX Orin SOM with 64GB LPDDR5 memory. Ideal for AI inference in autonomous systems, industrial visual inspection, and physical security, it features extensive I/O options, including 8x video-in (GMSL2), multiple LAN ports (1GbE, 10GbE, 2.5GbE with PoE+), USB 3.2, COM (optional CAN), DIO and M.2 slots for WiFi and 5G/LTE connectivity. This compact yet robust solution ensures seamless integration for edge AI applications. NVIDIA JetPack SDK 6.2 Support NVIDIA Metropolis stack for vision AI workloads, CUDA-X™ accelerated libraries, and robust development tools Seamlessly integrated with the NVIDIA JetPack™ SDK 6.2, both EAI-I251 and I233 empower developers with access to Jetson™ Linux, NVIDIA Metropolis stack for vision AI workloads, CUDA-X™ accelerated libraries, and robust development tools, accelerating the deployment of AI-driven in-vehicle video analytics. “With the NVIDIA Jetson platform, our latest edge AI computers redefine industrial AI performance, reliability, and connectivity,” said Spencer Chou, Senior Director of the Edge AI Division at Lanner Electronics. Advancements in AI and edge computing Chou added: “Introducing these innovations at NVIDIA GTC 2025 underscores our commitment to driving advancements in AI and edge computing for mission-critical applications.” The EAI-I233 and EAI-I251 will debut at Lanner's Booth #1908 during NVIDIA GTC 2025, Mar 17-21, at San Jose Convention Center. Visitors can experience live demonstrations and explore how these platforms enable real-time AI inferencing across industrial sectors.

Luxi Island microgrid system, which was designed, supplied, commissioned and delivered by NR, has been successfully put into operation. The system effectively solved the black start problem of 10kV feeder level microgrid with impulsive load, and has won high recognition from users with an advanced and intelligent control strategy, a stable and reliable microgrid system. Power supply of Luxi Island The power supply of Luxi Island was transmitted remotely by submarine cables Luxi Island is located on the east coast of China. The power supply of Luxi Island was transmitted remotely by submarine cables, which was easy to cause power supply interruption due to cable and tower damage. Due to the weak load carrying capacity of the original microgrid system, complex black start steps, difficult operation and low success rate, once the power was cut off, the recovery time was long, which seriously affects the production and life of residents on the island. Microgrid energy management system NR provides microgrid integrated solutions, including a microgrid energy management system, a microgrid coordination controller, an energy storage converter, and other core equipment, which effectively solves the existing problems. A microgrid system was required to quickly restore power supply after a power loss of the large power grid, and the black start function was the most important means to restore power supply and an important guarantee for the stable operation of the system. 10kV distribution network feeders usually have a large number of T-connected transformers, large load capacity. Research of microgrid technology NR successfully realized the black start function under the condition of full input of 10kV The simultaneous start of transformer inrush current and a large number of motor loads was easy lead to black start failure. The automation level of the existing distribution network system was low, relying on the manual opening and closing switch of the operation and maintenance personnel, and the power failure time of the system was long. In view of these problems, based on the long-term accumulation in the research of microgrid technology, NR successfully realized the black start function under the condition of full input of 10kV feeder load through intelligent one-key black start control and flexible synchronous parallel start technology of multiple converters. Technical advantages of NR The whole process took less than 10s from the issuance of command to the stable establishment of bus voltage, and quickly realized power supply restoration of 18 transformers, 1359 resident users and 177 non-resident users. The power supply reliability of Luxi Island has been significantly improved. The successful implementation of the project has further consolidated the technical advantages of NR in the field of microgrid, and provided the solution for the local autonomy of the new distribution system with high distributed energy resource penetration. NR will continue to practice the corporate purpose of "creating value and serving society", and contribute more to the development of a reliable green power system.

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automation and ICS/SCADA security. Powered by the Intel® Xeon® 6 Processor, the ICS-P770 delivers exceptional compute performance, security acceleration, and high-speed connectivity for power grid applications. Designed to meet the most demanding requirements of modern digital substations, the ICS-P770 supports up to 512GB of DDR5 RDIMM memory and offers high-speed networking with four 2.5GbE RJ45, two GbE SFP, and two 25GbE/10GbE SFP/RJ45 interfaces. Redundant Storage Solutions The system provides multiple PCIe expansion slots, including 4 PCIe Gen5 slots, with support for HSR/PRP PCIe Card, ensuring seamless redundancy in the event of a network failure. Additionally, the industrial computer features four hot-swappable U.2 NVMe storage bays with RAID support, ensuring high-speed data logging and redundancy for critical energy applications. Strength Meets Security Designed to withstand harsh substation environments, the ICS-P770 features an IP30-rated rugged chassis with intelligent fan cooling and is certified for operation in extreme temperatures from -25°C to 55°C. Advanced security measures, including TPM 2.0 and Intel® QuickAssist Technology, ensure robust encryption, authentication, and secure remote access, making it an ideal choice for virtualization and SCADA security. Revolutionizing Substation Tech "Lanner Electronics' ICS-P770 is a game-changer for next-generation digital substations and virtual protection, automation, and control (vPAC). It offers unparalleled performance, availability, and reliability with its Intel® Xeon® 6 Processor (featuring 64 e-Cores), high-speed networking, network redundancy, and robust security features," said Dave Meng, Senior Director of Business Development for Power and Energy at Lanner. "This IEC 61850-3 certified server platform is designed to meet the most demanding requirements for substation virtualization.” Smart grid innovation Lanner invites industry professionals, system integrators, and energy leaders to Booth #5749 at DISTRIBUTECH 2025 for a firsthand look at how the ICS-P770 is transforming substation automation, real time analytics, and critical infrastructure protection.

Tolomatic Inc., an industry pioneer in innovative linear motion systems, will be showcasing its latest servo linear actuators at Automate 2025. Featuring an integrated servo motor, Tolomatic servo linear actuators are ideal for applications where dynamic movement, precise positioning and force repeatability are a priority. Tolomatic products Tolomatic products include the IMA and IMA-S linear servo actuators. These actuators feature integrated servo motors to save space and are available in both ball and roller screw configurations. Their space and weight efficiency benefit compact machine designs, and their durable construction makes them resistant to shocks and vibrations. Ongoing maintenance requirements As servo linear actuators, they reduce commissioning time and ongoing maintenance requirements. The IMA-S is a stainless steel IMA actuator with an IP69K-rated, hygienic design ideal for the most demanding food and beverage applications, including washdowns. Tolomatic will be featuring its servo linear actuator designs at Automate 2025, detailing how they work and exploring their applications, including food, beverage, plastic, and automotive manufacturing.

Expert Commentary

Fleet electrification provides opportunities to achieve climate goals while delivering social, financial, and environmental benefits to individuals, businesses, and communities, but the road to successful EV implementation is not without obstacles. Your EV fleets need to work — all the time under varying conditions — to ensure optimal uptime while maintaining energy efficiency. Consequently, electric vehicle service equipment (EVSE) can’t just be “tacked onto” your existing operation. Rather than a “new standalone addition,” it requires a thoughtful and forward-looking approach to seamlessly integrate into your overall facility. Ensuring the type of reliable power needed for an electrified fleet is critical. Luckily, there are a number of new and emerging solutions that promise to deliver clean and reliable local power generation. The Challenges The availability and reliability of the power needed to support electrified fleets is a primary roadblock for many commercial fleet operators. It’s important to look at where that power comes from, how much it will cost, and whether it will be available when needed. Projections indicate that the demand for electricity will surge by 50% during the next two decades Today’s energy landscape is complex. Projections indicate that the demand for electricity will surge by 50% during the next two decades, with no signs of slowing down. According to Grid Strategies, the U.S. electric grid is not prepared for this level of significant load growth. The sheer amount of power needed to keep trucks charged and running 24/7 can be substantial. This poses a key risk for reliability in EV infrastructures, particularly in mission-critical situations. In addition, most fleet operators have become accustomed to fairly predictable fuel costs, since many take advantage of long-term supply arrangements. By contrast, electricity grid costs can vary and result in unpredictable spikes. This adds an extra layer of complexity when it comes to the planning and timing of fleet charging. As a result, many fleet charging operations are turning to local power generation. Intelligent Microgrids, the Energy Insurance Microgrids are nothing new, with rural communities relying on them for decades. Increased affordability and shifting regulations are allowing for more of these microgrids to be powered by renewable energy methods. A common misconception is that microgrids can completely off-set power from the grid. In reality, they are designed to provide peak load shaving and system resiliency. Coupled with an EV infrastructure, microgrids can offer more flexible and reliable energy management. When compared to a traditional microgrid for a building system, microgrids for fleet electrification present new challenges. Most notably, microgrids for fleet electrification are not modeled on an existing load, but rather anticipated demand, which can make reliable load-based modeling more difficult. However, an "intelligent" microgrid uses control systems to manage, store, charge, and discharge energy across the system. Strategic energy management The system can buy power from the grid during low-cost periods while storing self-generated solar power These controls monitor supply and demand, track real-time electricity prices, and create efficient charging schedules, considering factors like Time of Use (TOU) and peak day rates. For example, when electric fleets plug in, demand may increase significantly overnight, making strategic energy management crucial. The system can buy power from the grid during low-cost periods while storing self-generated solar power for later use. When prices rise, it discharges stored energy, keeping costs stable. It can also operate independently, ensuring continuous power during outages and disruptions, improving efficiency, cost control, and reliability. Conversely, fleets often permit charging flexibility within defined boundaries, providing a unique dispatchable resource that can be tuned to fit the needs and energy resources of the customer. A New Category of Local Power Generation Linear generator technology is proving to be an innovative solution for EV infrastructures by providing flexible, resilient and cost-effective on-site base load power. Linear generator technology provides fuel-flexibility meaning they can directly run and switch among traditional fuels like natural gas or propane. Or, they can use low and zero-carbon fuels such as RNG, biogas, hydrogen, and ammonia. Its backup capabilities ensure power through hurricanes, sub-zero snowstorms, excessive heat, and other extreme conditions. Based on capex and operating costs, linear generators can provide a competitive levelized cost of ownership compared to grid power or other alternatives in certain regions. Net-zero goals These solutions allow for flexibility and integration of new fuels as they become available The technology can also be quickly deployed at scale, which is ideal for large fleet operators looking to quickly and cost-effectively deploy resilient EV charging infrastructure while reducing emissions and working toward net-zero goals. What’s more, linear generators deliver a more “future-proof” path. While the dominant sources of fuel for local power generation today is well understood, new and exciting fuels are on the horizon. These solutions allow for flexibility and integration of new fuels as they become available. All without having to replace or retrofit existing equipment. Experts Will Power the Future As companies look to integrate EVs into their operations, a well-thought-out plan for infrastructure is essential to ensure safety, reliability, and long-term success. The integration of onsite power systems will play a critical role in optimizing energy use, lowering costs, and maintaining system resilience. The good news is that energy management is becoming more flexible, ensuring that fleet electrification is not only sustainable but also cost-effective. To ensure a seamless transition and maximize the benefits of fleet electrification, many companies will be moving forward by working with experienced consultants and planners to create a future-proof infrastructure that meets both operational and environmental goals.

Even during the era of big business, most residential electrical service companies tend to be on the smaller end with less than 20% employing more than 100 workers. And, like most small businesses, electrical contractors probably assume that they don’t need public relations and that their advertising efforts are enough to sustain them. But this is a common misconception. PR isn’t a luxury reserved for million-dollar companies and can be used to help progressively scale your business in the long run. Lead generation companies If you’re like most electrical contractors, you are using the marketing and advertising advice that many other home service companies have taken over the years and have confined your advertising into avenues such as direct mail, lead generation companies, truck wraps and a reliance on third-party referral websites. That is one reason why adding PR to your marketing budget is a necessity While these are all good options, the problem is that your competition is also using the same marketing techniques you are using and are probably only reaching the same set of potential customers. That is one reason why adding PR to your marketing budget is a necessity if you want to rise above your peers in your market. Residential electrical services If you were to do a quick Google search for electrical contractors in your community, chances are you’d find page after page of similar options. And, if you aren’t on the first page of that list, you aren’t making much of an impact. But, with the right PR partner, you can build your company’s reputation and recognition so that it becomes synonymous with good residential electrical services. A public relations expert can help you develop campaigns that show you as a thought leader in your market while helping you secure earned media in your local news and trade publications. A public relations expert can help you develop campaigns that show you as a thought leader These methods increase your visibility. Strong visibility not only helps you reach a wider audience, it inadvertently helps you move up spots in Google rankings. The more mentions your company gets on social media, in the news and on other online platforms, the better Google ranks your website. what is Earned media So what is earned media? That’s media that isn’t paid for or owned by your company and includes media interviews, customer reviews and organic mentions on social media. And, it’s important because it is by far the most trusted form of publicity available. Studies have shown that more than 90% of consumer trust earned media over paid-for advertising. Consumers have become savvy to commercials and no longer uses ads as their main method of researching a potential service partner. But, it’s getting this earned media that can prove tricky for most electrical contractors. Most of you probably don’t know any journalists and you certainly don’t have time with your busy schedule to cultivate relationships with the media. Potential service partner A good PR expert can pitch your expertise and story ideas surrounding your company That’s where a PR agency can help. Many of them are former reporters or know the business well enough to have built relationships with many media outlets. A good PR expert can pitch your expertise and story ideas surrounding your company to media both locally and in trade publications. It’s also possible that you haven’t considered the need to consistently read and respond to your customers’ reviews online. This is important because studies have shown that more than 92% of consumers say they read online reviews before they purchase a product or hire a service provider. Social media game Since you do have a business to run, it may be difficult to carve out enough time to reply to these reviews – both the good and bad ones – in a way that is both effective and conciliatory. But, a PR partner does have the time and the experience to do this for you. But, a PR partner does have the time and the experience to do this for you Finally, PR helps you stay on top of your social media game. It’s not enough to simply have a company Facebook or LinkedIn page – you have to consistently post content and engage your followers. Coming up with something new to post is a challenge when you’re trying to schedule house calls, pay bills and hire quality electricians. Attracting new customers Once you have developed a PR strategy that helps you to promote your brand, increase your visibility and develop you and your company as the market leaders in your community, you’ll begin to notice that your brand is reaching a wider audience. And, it’s a proactive strategy that will help you influence the market in your favor. These positive messages help you grab the attention of your target audience and connect with them on a personal level. PR is about telling a good story to build relationships and it’s these relationships that will help you grow beyond that of your competitors. Heather Ripley is founder and CEO of Ripley PR, an elite, global public relations agency specializing in skilled trades, B2B tech and franchising. Ripley PR has been recognized by Entrepreneur Magazine as a Top Franchise PR Agency five years in a row and was named to Forbes’ America’s Best PR Agencies for 2021. She is the author of ‘NEXT LEVEL NOW: PR Secrets to Drive Explosive Growth for your Home Service Business.’

The promise of electric vehicles is closer to reality than ever before. New plans and investments at the federal level designate billions of dollars to move our country toward clean energy, including $2 million to help auto manufacturers retool facilities to increase EV production. Additionally, the Biden Administration has announced a goal to create 100% carbon-free electricity by 2035 and a net-zero carbon economy by 2050. Domestic EV marketplace The domestic EV marketplace has grown from 16,000 to more than 2 million vehicles in the last decade and is poised to expand at lightning speed over the next ten years. S&P Global mobility has predicted that by 2030, electric vehicles (EVs) will make up 40% of the U.S. market share of new vehicles on the road. This dramatic increase in EVs will require a nationwide network of charging stations to meet the demand from the current 140,000 to over 1.1 million. Charging stations It is a necessity that regulators lay the groundwork now for a reliable and secure charging networkThe expansion of charging stations will undoubtedly give zero-emissions drivers more confidence in their ability to refuel more conveniently. Still, it’s critical that confidence in infrastructure security also be prioritized alongside this growth. If not adequately protected and monitored, charging stations could serve as access points for cybercriminals, potentially leading to personal data leaks, attacks on vehicle systems, and even widespread blackouts. As EVs continue to gain momentum as realistic alternatives to CO-2 emitting vehicles, it is a necessity that developers and regulators lay the groundwork now for a reliable and secure charging network for the long term. EV Charging Infrastructure and the electric grid The nation’s electric grid generates and delivers electricity essential to everyday life. It’s made up of power plants and other sources of generated electricity, complete with transmission and distribution lines and infrastructure that delivers essential power. Grid connection An important aspect to remember about EV charging stations is that they connect to their relative electric grid. Simply put, the infrastructure for charging stations is comprised of devices that wait for another device to connect and communicate. However, it lacks a third-party firewall or other devices that can act as protection. Unfortunately, this results in vulnerability and means new doors for cybercriminals to walk through. Cybersecurity risks If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts Even before EV charging stations are factored in, the electric grid faces substantial cybersecurity risks from criminals, terrorists, hackers, and foreign governments every day. If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts that would undoubtedly affect EV charging stations and other essential institutions such as banks, hospitals, and gas stations. With the expansion of EV charging stations, the risks only grow. Now is the time to address threats and strategize before disaster strikes. Risks of connectivity emerge The world we live in has reached a level of being almost entirely connected at all times – security systems, appliances, health monitors, industrial sensors, and now, our vehicles. While the connectivity of vehicles has been incredibly beneficial to consumers and the automotive industry alike, the growth in the internet of things (IoT) has opened countless doorways for cybersecurity threats. Software flaws One young information technology security specialist reported finding flaws within a third-party software that a handful of leading EV manufacturers use. It gave him access to more than 25 EVs in at least 13 countries. The man, who stumbled on the findings in 2022, said he could remotely control some EV functions, including starting vehicles, unlocking windows and doors, disabling security systems, and turning on stereo systems and flashing headlights. The IT specialist said he could also tell if a person was in the vehicle. In a separate and concerning situation, a single compromised password led to a foreign-fronted cyberattack on a U.S.-based pipeline in 2021. It halted the fuel supply process on the east coast and cost the company $4.4 million in ransom money. Cyberattacks Thousands of charging stations are already in danger of being targeted by cybercriminals The point is that even massive and powerful companies can fall victim to cyberattacks. Even though cybersecurity is a critical issue for EV manufacturers, their systems are still vulnerable to hackers. Thousands of charging stations are already in danger of being targeted by cybercriminals, and as the number of stations grows, so too will the risk. The higher the number of entry points, the more opportunities hackers will see. If they can break into and gain access to even the most sophisticated EVs, it could be catastrophic. Ensuring security and reliability through proactivity Because charging stations are connected to the country’s primary grid, the entire infrastructure must be armed with the most aggressive security measures. The risks associated with modernized electric vehicles are not something that traditional automotive safety regulations and security standards properly cover. The complicated and rapid evolution of EVs is putting them at a heightened threat. When charging stations are connected to the electrical grid, it is imperative to ensure strong cybersecurity measures are in place to remain dependable and effective. Embedding cybersecurity technology We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection The best way to ensure the electric grid's safety is to build cybersecurity technology directly into the charging stations. We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection. Unfortunately, the promising growth EVs and their charging stations bring to our environment also contributes to technology’s vulnerabilities, which can cause key security measures to be overlooked. There’s no getting around it: EV charging stations are highly vulnerable to hackers. Awareness and solutions As the growth continues, there is an acute need for heightened awareness and solutions for the weaknesses associated with these charging stations. These solutions should consider everything from the charging points and devices to operators of the energy distribution networks and infrastructure providers. We must aim to implement advanced cybersecurity measures that will keep safe drivers and all the data that EVs contain.

Power Beat

Electricians play a pivotal role in preventing electrical fires by following safe practices during installations, repairs, and inspections. At a minimum, electricians should ensure all electrical wiring and components are installed according to current building codes and manufacturers' specifications. This includes using the right size wires for the amperage load, using approved materials, and properly securing all connections. During electrical inspections, electricians should identify and address any potential fire hazards. Electricians can also advise homeowners on electrical safety measures they can take to prevent fires. These include safe appliance use, avoiding overloaded outlets, and the importance of smoke detectors and fire extinguishers. Maintenance of electrical systems Ground Fault Circuit Interrupters (GFCIs) can prevent possible fires. GFCI outlets have built-in protection to detect imbalances in electrical current and quickly shut off power to prevent shocks and potential fires, particularly in areas prone to moisture like kitchens and bathrooms. Regular maintenance of electrical systems is also crucial for fire prevention. Electricians can perform preventative maintenance checks to identify and address any developing issues before they become serious fire hazards. Fire departments responded to an average of 32,160 home fires involving electrical distribution Fire departments responded to an average of 32,160 home fires involving electrical distribution and lighting equipment each year in 2015–2019, according to the National Fire Protection Association (NFPA). Electrical fires cause scores of civilian deaths and hundreds of civilian injuries, as well as millions of dollars in property damage. Fire Hazards in the Home Some of the electrical components that present fire hazards in the home include faulty electrical outlets and switches, worn or damaged components, overloaded circuits, damaged or frayed cords, and misused extension cords and power strips. Improper use of light fixtures can also be a danger, and space heaters can be a fire hazard if they are placed too close to flammable materials or left unattended. Damaged or frayed cords can cause sparks and ignite nearby flammable materials As outlets and switches age, the wiring behind them can loosen and break, causing sparks and fire. Loose plugs can also overheat and ignite surrounding materials. Plugging too many appliances into a single outlet or using extension cords instead of proper wiring can overload a circuit, thus causing overheating and fires. Damaged or frayed cords can cause sparks and ignite nearby flammable materials. Cords that are kinked, pinched, or have exposed wires should be avoided and replaced immediately. Minimizing the Risk of Electrical Fires Here are some steps a homeowner can take to minimize the risk of fire from electrical systems: Upgrade the electrical system, especially if the home is older. If the electrical system has not been updated in a while, a qualified electrician can advise if it needs modernization. This could involve upgrading to breakers with better safety features such as Arc-Fault Circuit Interrupter (AFCI) and Ground Fault Circuit Interrupter (GFCI) technology. Schedule an electrical safety inspection. Having a qualified electrician periodically inspect a home's electrical system can identify potential problems before they escalate into fire hazards. Keep flammable materials away from electrical components, including curtains, furniture, and piles of paper. Sparks and overheating can easily ignite nearby flammables. Addressing Multiple Threats Effective communication is key for electricians to impress upon homeowners the seriousness of fire hazards. Avoid technical jargon and explain fire hazards in clear, concise language that homeowners can understand. Focus on the potential consequences, like damage to property or injury, to heighten awareness. Pictures can be worth a thousand words. Show homeowners examples of damaged wiring, overloaded outlets, or faulty installations that pose fire risks. This can be done through photos on a tablet or phone, or even carrying around small physical samples. Frame the conversation around safety for the homeowner and their family. Highlight how addressing these hazards can prevent potential fires and ensure a safe living environment. Provide a written report after the inspection or repair. This report should detail the identified hazards, the corrective actions taken, and any recommendations for future maintenance or upgrades. By combining clear communication, visual aids, and a focus on safety, electricians can effectively convey the importance of addressing fire hazards to homeowners and empower them to make informed decisions about their electrical systems.

The electrical industry is expected to have a labor shortage of about 60,000 workers by 2026. A labor shortage in the electrical trade is not inevitable, but it is likely to continue if the industry does not take steps to address the issue. Like other skilled trades, the electrical industry is facing challenges that could contribute to a labor shortage, including an aging workforce, a lack of interest among younger generations, and competition from other industries. However, there are strategies the industry can implement to address these challenges and attract a new generation of workers. These strategies include increasing awareness of the benefits and opportunities of skilled trades, investing in training and education programs, improving working conditions and compensation, embracing technology, promoting diversity and inclusivity, and collaborating among industry, education, and government. Improving working conditions Factors in the current labor shortage in the electrical industry include: Aging workforce: Many workers in the electrical industry are nearing retirement age, and there are not enough younger workers to replace them. This has led to a shortage of skilled workers with many years of experience in the industry. Lack of interest in the trades: There has been a decline in the number of young people pursuing careers in the skilled trades, including electrical work. This is due in part to a focus on four-year college degrees as the preferred career path, as well as a lack of awareness of the benefits and opportunities of skilled trades. Competition from other industries: The electrical industry is competing with other industries, such as construction and manufacturing, for skilled workers. Training and education: Training and education are critical for developing the skills and knowledge necessary for electrical work. However, there is a shortage of qualified trainers and educators. Increasing demand: The demand for electrical services is increasing, particularly in areas such as renewable energy and smart grid technology. Attracting and retaining workers To attract and retain workers, the electrical industry must offer competitive wages and benefits One strategy to address the labor shortage is to increase awareness of skilled trades and to promote the benefits of a career in the electrical industry through outreach programs in schools, career fairs, and other events. Providing access to quality training and education programs that develop the skills and knowledge necessary for electrical work is crucial for attracting and retaining workers. This can be done through apprenticeship programs, vocational schools, and community colleges. To attract and retain workers, the electrical industry must offer competitive wages and benefits, as well as a safe and supportive work environment. This includes offering training and development opportunities, flexible schedules, and opportunities for advancement. Inclusive work environment The electrical industry is changing rapidly, and workers must be equipped with the latest technology and tools to stay competitive. Providing workers with training and access to the latest technology can help attract and retain workers. The electrical industry should actively promote diversity and inclusivity to attract a wider pool of workers. This includes efforts to recruit workers from underrepresented groups and create a welcoming and inclusive work environment. The electrical industry is changing rapidly, and workers must be equipped with the latest technology Companies in the electrical industry are addressing the labor shortage problem by investing in workforce development programs and initiatives. For example, Schneider Electric has developed a comprehensive workforce development program called the Schneider Electric Energy and Automation Training (SEAT) program. The SEAT program provides training and certification for employees, customers, and partners in areas such as energy management, automation, and digital transformation. Developing training programs Siemens has developed several initiatives to address the labor shortage in the electrical industry. These initiatives include apprenticeship programs, vocational training programs, and partnerships with educational institutions to develop training programs. Graybar, a distributor of electrical products and solutions, has developed a workforce development program called Graybar University to provide training and education for employees, customers, and partners in areas such as lighting, automation, and safety. Joint apprenticeship training program Collaboration among industry, education, and government is crucial for developing solutions The International Brotherhood of Electrical Workers (IBEW) and the National Electrical Contractors Association (NECA) have developed a joint apprenticeship training program that provides training and education for individuals looking to enter the electrical industry. The program provides on-the-job training and education in areas such as electrical theory, safety, and installation. Collaboration among industry, education, and government is crucial for developing solutions to the labor shortage in the electrical industry. This includes partnerships between industry and education institutions to provide training and education programs, as well as government initiatives to support workforce development in the skilled trades.

Many economists are predicting a recession in 2023, although most agree business conditions should improve by the end of the year. For the electricals market, numerous factors are in play that can offset the downturn, and any projections must also consider the variables of the local market (rather than the national or international outlook). Economic weakness and challenges The Conference Board forecasts that economic weakness will intensify and spread more widely throughout the U.S. economy over the coming months with a recession starting in early 2023. Real GDP growth was expected to be 2.0 percent year-over-year in 2022, then slow to 0.2 percent in 2023, and later rebound to 1.7 percent in 2024, according to the Conference Board. 2023 comes on the heels of a challenging year for electricals, when price increases and product shortages were a stark reality. Impact of higher prices A troubled geopolitical environment provides an additional source of economic uncertainty Sales growth numbers in 2022 were skewed by the impact of inflation: How much of the bigger numbers were “real growth” and how much reflected the impact of higher prices? Higher prices accounted for the lion’s share of revenue growth by some estimates, with real growth in the low single digits. A troubled geopolitical environment, exemplified by the war in Ukraine and a continuing COVID crisis in China, provides an additional source of economic uncertainty. environmentally friendly technologies A positive factor that may offset the fragile outlook in 2023 includes an overall trend toward greater electrification and away from less energy-efficient power sources. Governments around the world are pushing for more environmentally friendly technologies, which provides positive headwinds for the electricals market. In the United States, for example, the Inflation Reduction Act, passed in August 2022, includes government investments and tax incentives to drive the transition to a greener world, including $27 billion to deploy low- and zero-emissions technologies, and $1 billion more each for advancing zero-emissions heavy-duty vehicles and for zero-energy building code adoption. Tax incentives Another $750 million will be spent to establish interstate electricity transmission lines, and $87 million will go to low-emission electricity programs. Tax incentives will provide new inducements for consumers to transition to electric technologies, which means more business for the broader electrical market. The government is also encouraging investment in infrastructure spending and the construction of factories for a variety of electrical products. Residential construction The higher interest rates present affordability challenges for home buyers and a slowdown in the market Residential construction, a big factor in the electricals outlook, has slowed down considerably in 2022, and the trend will likely continue into 2023. The U.S. Federal Reserve has raised interest rates by a total of 4.25 percentage points in 2022, a trend that is reflected in the interest rates charged to homebuyers. Mortgage rates for a 30-year fixed mortgage increased from 3.2% to 6.3% in 2022. The higher interest rates present affordability challenges for home buyers and a slowdown in the market for single-family construction. Markets in the Sunbelt are less affected, but data on housing starts and building permits nationwide reflect the slowdown. Non-residential construction Non-residential construction has held up well in 2022, but demand is weakening in the new year, while a backlog of projects will likely preclude the worst of the impact, although the business pipeline will eventually be depleted. A troubling long-term trend for the construction market, and by extension the electricals market, is the tendency of companies to allow employees to work from home at least part of the time. The apparent eventual consequence is to lower the demand for office space, already reflected in lower occupancy numbers in some markets. Less construction means less demand for electrical products and services. Obviously, the long-term trend lines are still uncertain. Supply chain woes Supply chain woes and longer lead times continued to plague the world market at the start of 2023, although the situation has improved since the worst of times. Lead times are still months longer than normal, and products powered by semiconductor chips, such as lighting controls, are especially a challenge. An employee shortage continues as companies in all sectors of the electricals market struggle to find enough employees to fill their needs. The shortage stimulates opportunities for companies to work smarter and to provide more preassembled electrical products to simplify installation.

Case studies

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.

Quanergy Solutions, Inc., a provider of 3D LiDAR (Light Detection and Ranging) security solutions, was chosen by Vancouver International Airport (YVR) to analyze footfall to support the passenger journey with the ultimate goal of enhancing operational efficiencies. Quanergy’s technology is delivering accurate data-driven insights for YVR’s Domestic Check-in and Security Screening facilities. Real-time insights “Through the implementation of Quanergy’s solutions, we have harnessed the power of real-time insights, gaining a deep understanding of passenger volumes and the associated wait times at different stages of their journey through the terminal,” said Jason Williams, Manager of Innovation & Technology Group, YVR. He adds, “With this high-precision data at our disposal, we can trigger real-time alerts whenever we approach or exceed predefined thresholds. This invaluable capability enables us to collaborate seamlessly with our stakeholders, ensuring that our travelers experience a smooth and stress-free journey through our airport.” Q-Track YVR currently uses insights to meet several operational and business imperatives, such as reducing check-in time With Quanergy’s 3D LiDAR sensor and advanced perception software solution, Q-Track, YVR can accurately identify, classify, and track people/objects for enhanced operational insights. YVR currently uses these insights to meet several operational and business imperatives, such as reducing check-in time and time spent passing through security, which ultimately sees an increase in customer happiness. streamline operations “We are pleased to have collaborated closely with the YVR team, resolving a multifaceted challenge encountered by many passenger terminals today,” said Adam Andres, Vice President of Global Sales at Quanergy. He adds, “The forward-thinking of the YVR Innovation and Technology Group, in embracing Quanergy’s field-tested and fully scalable Q-Track solution, led to the achievement of our project objectives. We take pride in our contribution, providing real-time actionable intelligence to enhance security, streamline operations, and elevate the overall passenger experience.”

Mota-Engil, a multi-national with activities focused on the construction and management of infrastructures, responsible for the construction of the Canoas wastewater lifting station, selected WEG as the provider of a large package of electrical solutions for an important initiative to decontaminate the waters of the Bogotá River, in Colombia. Sustainable development When the project is completed, the pumping station will receive the wastewater from approximately 70% of the city, corresponding to the Fucha, Tintal, and Tunjuelo river basins, and the wastewater from the Municipality of Soacha, to be later pumped to the future Canoas Wastewater Treatment Plant, which will be one of the largest in Latin America. This great milestone will make it possible to return quality water to the Bogotá River and guarantee the sustainable development of the country. Safe distribution of energy Seventeen medium voltage switchgears were also supplied in addition to low voltage load centers One of the great challenges of this project is to guarantee the safe distribution of energy to the electrical systems and motors. For this, WEG has supplied a complete 115 kV substation that includes two 30 MVA/115/13.2 kV transformers, adding more efficiency and reliability to the plant. 17 medium voltage switchgears were also supplied in addition to low voltage load centers. For this project, WEG will also be supplying six three-phase induction motors and six medium voltage variable frequency drives. Each 4,300 kW motor, vertically mounted, will be coupled to its respective pump and will be responsible for pumping 6.4 cubic meters of wastewater per second to 51.6 meters height from the well, one of the most critical processes in the plant. Improvement of the quality of life This demonstrates the company's ability to develop integrated solutions that meet the most diverse applications. With participation in other important projects in the water and wastewater segment, in various processes such as potable water treatment plants, wastewater treatment, and distribution systems, WEG reinforces its experience in this segment by being selected for this important project, thus contributing to the improvement of the quality of life of the population and the environment.

SoFi Stadium, a world-class venue, turned to industry major - Belden for a complete end-to-end cabling and connectivity solution. Belden’s cutting-edge technology supports the stadium’s data-heavy demands, including the one-of-a-kind, roof-suspended Oculus video board, Wi-Fi infrastructure, digital ticketing, and a DAS system. Belden’s solutions for SoFi Stadium When the stadium’s owners required a solution that delivered top-tier quality, performance, and reliability while reducing labor costs, they called Belden. Count on Arrow to deliver unparalleled excellence in the low-voltage industry. Arrow will equip with the competitive advantage needed for any customer, any configuration, and any budget. Copper Cables & Copper Solutions Discover the ultimate lineup of Belden Inc. category cables, tailored to suit every application imaginable! Discover the ultimate lineup of Belden Inc. category cables, tailored to suit every application imaginable! Many cables featured their signature patented Bonded-Pair design, guaranteeing unparalleled signal integrity. Plus, with DataTuff® Industrial category cables, rest assured the system remains resilient against the toughest environmental conditions. Category 6A Choose from an assortment of configurations including small diameter, snake, industrial, non-bonded, and their innovative patented Bonded-Pair technology. Elevating performance benchmarks, Belden's renowned 10GXS Cable stands as the gold standard in the industry. Category 6 Belden has a wide array of Category 6 performance options, featuring their top-of-the-line REVConnect 3600 System cable boasting premium performance and ample headroom. The REVConnect 2400 System cable, surpasses TIA-568-C.2 standards, all backed by Belden’s renowned quality. Category 5e Belden presents a range of Category 5e performance options, with their flagship 1200 Series cable delivering exceptional headroom, surpassing the TIA-568-C.2 Category 5e standard. Featuring Bonded-Pair technology, their 1200 Series ensures unparalleled robustness in installations. Patch Panel Belden’s commercial-grade panels are available in modular (empty) configurations Belden offers a comprehensive range of copper patch panels tailored to meet the demands of both commercial and industrial settings. Belden’s commercial-grade panels are available in modular (empty) configurations or pre-loaded with high-quality copper jacks designed for Category 6A, 6, and 5E network installations. Trunk Cable Optimized for data centers, enterprise networks, and any environment prioritizing swift installation, Trunk Cable Assemblies offer factory termination and rigorous testing, slashing installation time by up to 90%. Eliminating the need for termination, these assemblies come in diverse lengths, equipped with connectors tailored to specific application requirements. Patch Cord Enhancing both performance and physical durability, Belden’s Copper Patch Cords ensure optimal transmission quality for network channels. With superb return loss characteristics adaptable to any environment, Belden’s Copper Patch Cords come in modular, small-diameter, and traceable solutions to meet specific needs. Fiber Cable & Fiber Solutions Discover an array of high-quality indoor and outdoor cable solutions within Belden’s comprehensive product line, featuring both tight buffer and loose tube designs. Tailored for diverse industrial settings, their offerings include armored, burial, and ruggedized options. Crafted to meet various specifications, their product range encompasses OM1, OM3, OM4, OM5, and OS2 (Single Mode) configurations. Tight Buffer Fiber Cables Tight-Buffered Fiber Cables are perfectly tailored for enterprise environments Tight-Buffered Fiber Cables are perfectly tailored for enterprise environments, these cables stand out as a crowd favorite, ideal for intra-building backbones and both horizontal and vertical installations. Offering versatility like no other, they come in fiber counts ranging from two to an impressive 144, making them adaptable to any project scale. Whether indoors or outdoors, these cables are engineered to exceed expectations, boasting a design that ensures seamless performance in any environment. Loose Tube Cables Belden’s Loose Tube Cables offer the ultimate solution for all outdoor and indoor/outdoor fiber optic needs. Whether it’s for OSP, conduit, direct burial, aerial, or trunking applications, Belden’s cables offer unmatched versatility and performance. Choose from a variety of options including dry or gel-filled single and double-jacket designs, with plenum and riser ratings. Armored Cables Belden’s armored cables are designed to withstand harsh environmental conditions, including extreme temperatures, moisture, and physical damage. The armor layer provides an extra level of protection against mechanical stresses, such as crushing, impact, and abrasion, ensuring the longevity and reliability of the cable. It also helps to maintain cable integrity in areas prone to disturbances such as rodent activity. Connectors Belden’s connectors seamlessly integrate fusion splicing with field-installable connectors Belden’s connectors seamlessly integrate the advantages of fusion splicing with the ease of field-installable connectors, they greatly enhance flexibility for field termination, while elevating installation performance and reliability beyond traditional mechanical splice connectors. Eliminating the need for crimping, polishing, or adhesives during termination significantly reduces installation errors. Cassettes Belden offers an advanced DCX and LAN Cassettes platform designed to cater to a wide spectrum of density requirements, ranging from low to ultra-high density applications. Cassettes platform encompasses frames, cassettes, and covers for a comprehensive array of connector types, including LC, SC, ST, and MPO connectors, as well as Copper RJ45 Jacks and Couplers. Patch Cords Simplified, durable, adaptable, and readily accessible. Unmatched quality and performance define Belden's FX patch cords, engineered with a robust design to endure daily wear and tear. Available in standard configurations off the shelf or swiftly customized for tailored installations, they ensure reliability in any setting.