Transportation

Hitachi Astemo, Ltd. (hereafter “Astemo”) and GlobalLogic Inc. (hereafter “GlobalLogic”) have been strengthening their collaboration to lead the trends of software-defined vehicles. Astemo President & CEO, Kohei Takeuchi and GlobalLogic CEO, Nitesh Banga discussed the future of mobility through digital transformation. As a global mega-supplier, Astemo has been providing tangible value in the In-Car domain as internal vehicle technology, such as software that enables...

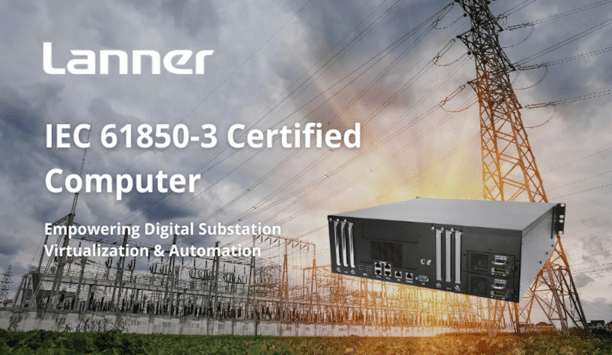

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U...

Lanner Electronics, a pioneer in network computing appliances and industrial AI computers, will officially unveil its latest innovation, the EAI-I233 and EAI-I251 industrial-grade Edge AI computers, at NVIDIA GTC 2025. Powered by the NVIDIA® Jetson AGX Orin™ system on module (SOM), these advanced platforms are designed to deliver low-latency AI inferencing capabilities at the edge for industries including retail, manufacturing, transportation, and smart city. EAI-I233: AI inference s...

Recently, Baihetan - Zhejiang ± 800kV UHV DC transmission project (referred as "Baizhe project") has been completed, and put into operation. The BaiZhe Project is a major clean energy project to promote the energy structure adjustment, energy conservation and emission reduction. It shoulders the strategic mission of delivering the power of the world's second largest hydropower station which is Baihetan hydropower station. New power giant dragon The project starts from Jinsha River conv...

Siemens is ramping up investments in the U.S. to support and benefit from America’s industrial tech growth. “The industrial tech sector is the basis to boost manufacturing in America and there’s no company more prepared than Siemens to make this future a reality for customers from small and medium sized enterprises to industrial giants,” said Roland Busch, President and CEO of Siemens AG. Recent investments of Altair The $285 million investment is expected to create ov...

On April 14, GlobalLogic Ukraine organized the largest Eastern European technical conference on software development, Root Linux Conference 2018. Hosted in Kyiv, the conference focused on Linux, Embedded, and Automotive topics and featured 20 speakers from all across Europe, including representatives from prominent organizations such as Cisco, Citrix, DENX, Intel, Linaro, Samsung, and SUSE Linux. Root Linux brought together nearly 400 open-source developers and embedded engineers from 16 Ukrain...

News

The Via Inspirada Center for Excellence (VICE), an endeavor by the City of Henderson, is set to become a nexus of education and training. Throughout the construction process, GSL Electric played a pivotal role in delivering an exceptional electrical installation. Let's delve into the details of the contributions the GSL Electric team brought to the VICE project. Navigating unique challenges GSL Electric's skilled team came these challenges head-on, turning the hurdles into opportunities Every project presents its unique set of challenges, and VICE was no exception. With a significant portion of the building constructed using block material and an owner's emphasis on concealed conduits, the routing and installation of the electrical system demanded meticulous planning and execution. GSL Electric's skilled team approached these challenges head-on, turning the hurdles into opportunities for creativity and innovation. Their expertise and attention to detail ensured a seamless integration of the electrical system within the architectural framework, resulting in a remarkable outcome. Exceeding expectations The Via Inspirada Center for Excellence spans an impressive 17,000 square feet, and hosts a state-of-the-art advanced manufacturing training program, a public art gallery, and the city's economic development department. GSL Electric, with an average crew size of only three field electricians, invested a total of 4,626.5 labor hours into this transformative project. Their combined decades of experience were the key to delivering superior results thoughout every step of the construction process. Electrical specs GSL Electric ensured that every wire, every link, and every part adhered to the highest industry norms Under GSL Electric's expert guidance, the electrical system at VICE stands as a testament to their technical prowess and commitment to excellence. The installation involved a staggering 32,175 linear feet of electrical cable and 30,592 feet of conduit. The electrical service installed, a 1200A 277/480V 3 phase, 4W, 42K AIC, provides a robust and reliable power supply to support the facility's diverse needs. With precision and care, GSL Electric ensured that every wire, every connection, and every component adhered to the highest industry standards, guaranteeing the safety and efficiency of the electrical infrastructure. A culture of safety At GSL Electric, safety is not just a priority; it is ingrained in every aspect of their work. The Via Inspirada Center for Excellence project is a shining example of GSL Electric's unwavering commitment to safety. Throughout the entire project duration, not a single OSHA injury was reported, demonstrating GSL Electric's dedication to maintaining a safety-first culture. Field leaders and the entire GSL Electric team worked diligently to ensure a safe working environment for everyone involved. Celebrating team excellence Jerry and Omar exhibited exemplary workmanship, dedication, and unwavering commitment While the success of the Via Inspirada project can be attributed to the collective efforts of the entire GSL Electric team, special recognition is due to two exceptional individuals: Jerry Tewes and Omar Perez. From the project's inception to its completion, Jerry and Omar exhibited exemplary workmanship, dedication, and unwavering commitment. Their contributions were invaluable, and their attention to detail helped achieve outstanding results. Unwavering commitment to safety The Via Inspirada Center for Excellence stands as a testament to the power of collaboration, innovation, and meticulous craftsmanship. It would not have been possible without a team dedicated to bringing their best to the project. Their ability to overcome unique challenges, deliver exceptional electrical construction, and maintain an unwavering commitment to safety demonstrates their expertise and professionalism.

Siemens eMobility has been selected as the technology partner for two major electric vehicle (EV) charging infrastructure projects in Italy. Partnering with Autolinee Toscane and IPLANET, Siemens eMobility is driving the electrification of public transportation and the transformation of petrol stations into strategic service areas, further advancing sustainable mobility in the region. Siemens’ innovative technology Siemens eMobility is electrifying multiple bus depots for Autolinee Toscane Siemens eMobility is electrifying multiple bus depots for Autolinee Toscane, a major public transport operator and part of RATP DEV Italia Group, in the cities of Florence, Prato, and Lucca, supporting the rollout of the company’s zero-emission bus fleet. Leveraging Siemens’ innovative charging infrastructure technology, this project ensures efficient and reliable operations across Tuscany’s public transport network. 73 charging points for Autolinee Toscane S.p.A. The project consists of a total of 73 SICHARGE UC charging points, capable of supplying 100 and 150 KW of power to charge electric vehicles. In addition, Siemens supplies medium and low-voltage electrical distribution systems with switches equipped with IoT modules to ensure a reliable and transparent energy supply. Siemens eMobility also provides DepotFinity, a software platform for monitoring, reporting, programming and managing charging operations within the depots. The main benefits for Autolinee Toscane are the monitoring of charging processes with the implementation of optimized smart charging logics of loads based on the operator's service, pre-conditioning functionality of vehicle batteries and reporting of the kilometers traveled by each individual vehicle. Advanced charging infrastructure for 120 IPLANET service sites In another project, IPLANET, a renowned energy transition solutions provider, has tasked Siemens eMobility with equipping over 120 logistics sites with advanced charging infrastructure, featuring integrated Point of Sales (POS) systems compliant with Alternative Fuels Infrastructure Regulation (AFIR), activation via app or QR code, and interactive screens ensuring accessibility also for users with disabilities. The network includes hundreds of 300-400 kW charging points, all fully remotely monitored through independent connectivity channels to ensure high reliability and availability. Integration with renewable energy sources The sites also incorporate Siemens medium and low voltage electrical distribution systems The sites also incorporate Siemens medium and low voltage electrical distribution systems, scalable compact transformer substations, and telecontrol capabilities, enabling integration with renewable energy sources. Additionally, some of the turnkey service areas, including photovoltaic installations, parking area battery energy storage systems (BESS), and facilities for heavy-duty EV charging (e-trucks), are already operational. Driving sustainable mobility together "Projects like these underscore Siemens eMobility’s mission to integrate sustainable mobility into everyday life. By combining cutting-edge technology and strong partnerships, we’re helping to transform the transportation and logistics sectors for a more sustainable future," said Markus Mildner, CEO of Siemens eMobility. Siemens eMobility’s portfolio spans IoT-connected hardware, software, and services for both AC and DC charging, supporting applications from 11 kW to 1 MW. With a strong focus on the fast-growing eBus and eTruck market, the company continues to lead the way in providing comprehensive solutions tailored to diverse customer needs. impactful eMobility solutions With over 100,000 charging points installed and 800 projects completed in more than 60 countries, Siemens eMobility combines global expertise with local execution. The partnerships with Autolinee Toscane and IPLANET reaffirm its commitment to innovation, collaboration, and sustainability in delivering impactful eMobility solutions.

Siemens Mobility has been awarded four significant contracts by HS2 Ltd and will join key contractors under the Rail Systems Alliance. Siemens Mobility will play a crucial role in the delivery and operation of the new 225-kilometer-long British high-speed railway that will connect London and the West Midlands. Capacity and energy efficiency For the first time, Siemens Mobility will implement wayside Automatic Train Operations [ATO] over the European Train Control System [ETCS] Level 2 on a high-speed network, enabling semi-automatic train operations (Grade of Automation 2) for improved capacity, punctuality, and energy efficiency. Another contract focuses on an Engineering Management System that will enable real-time control and monitoring of railway equipment, ultimately enhancing reliability and efficiency. high-voltage power supply All awarded contracts are expected to commence in 2025 with a total order value of approximately 670 million Euros Siemens Mobility also formed a joint venture with Costain Ltd to deliver high-voltage power supply systems along the HS2 route. Finally, Siemens Mobility will take charge of implementing Operational Telecommunications and Security Systems for the entire HS2 route. All awarded contracts are expected to commence in 2025 with a total order value of approximately 670 million Euros, including long-term maintenance agreements, and potentially including additional options. electrification technology “HS2 is set to transform rail travel by offering faster and more reliable passenger journeys and freeing up freight paths in the UK. We are very proud to provide our wayside ATO over ETCS solution, enabling semi-automated train operations for improved capacity, punctuality, and energy efficiency on high-speed travel for the first time. Furthermore, we will deliver cutting-edge electrification technology and maintenance support for this groundbreaking project," said Michael Peter, CEO of Siemens Mobility. “HS2 will play a vital role in connecting the UK’s two largest cities and driving growth and sustainability nationwide. With our 5,500 UK employees, Siemens Mobility is fully committed to delivering advanced transportation solutions designed and built in Britain.” Command, Control, Signaling & Traffic Management [CCS&TM] Siemens Mobility will design, manufacture, supply, install, supervise, inspect, safety authorize, test, commission, and maintain a state-of-the-art European Train Control System [ETCS] Level 2 signaling system and traffic management solution with wayside Automatic Train Operation at GoA2. This solution will eliminate the need for traditional signals along the tracks by providing digital signaling Building on Siemens Mobility's successful signaling technology implemented in projects like Thameslink and the East Coast Digital Programme, this solution will eliminate the need for traditional signals along the tracks by providing digital signaling that feeds information directly to the train driver via a screen in their cab. This will improve operations and substantially simplify maintenance compared to conventional train control systems. Siemens Mobility will provide technical support services for the system for at least 15 years. Engineering Management System Siemens Mobility will design, manufacture, supply, install, integrate, test, commission, and maintain an integrated Supervisory Control and Data Acquisition [SCADA] system that will enable real-time control and monitoring of railway equipment, ultimately enhancing reliability and efficiency, utilizing the company's technology and provision of maintenance and technical support. Siemens Mobility will leverage its 50 years of experience in delivering advanced SCADA systems from projects such as the Elizabeth Line in London. Siemens Mobility will provide technical support services for the system for at least 15 years. High voltage [HV] power supply systems As part of the construction of HS2, traction and non-traction substations will be built alongside the railway line A Siemens Mobility and Costain joint venture will design, manufacture, supply, install, test, commission, and maintain a high-voltage power supply system for the HS2 high-speed rail project. As part of the construction of HS2, traction and non-traction substations will be built alongside the railway line. These sub-stations will play a critical role in facilitating the delivery of power from the National Grid to high-speed trains and other railway systems, ensuring their efficient and reliable operation. Siemens Mobility and Costain will provide maintenance services for the system for at least seven years. Operational Telecommunications and Security Systems Siemens Mobility will design, manufacture, supply, install, safety authorize, test, commission, and maintain an Operational Telecommunications and Security System along the HS2 route. This will provide Global System for Mobile Communications-Railway [GSM-R] secure, digital, wireless communications between drivers along the route. Passive provision will be made for an upgrade to the Future Railway Mobile Communication System [FRMCS]. The company will provide technical support services for the system for at least eight years. HS2: Set to transform rail travel in Britain As Britain's second purpose-built high-speed railway, HS2 follows in the footsteps of High Speed 1 HS2, the new high-speed railway currently being constructed, is set to transform Britain’s transportation landscape. Spanning 225 kilometers, the line will connect London to Birmingham with a spur to Handsacre, connecting HS2 trains to other UK cities in the North West and beyond. As Britain's second purpose-built high-speed railway, HS2 follows in the footsteps of High Speed 1, which links London to the Channel Tunnel. HS2 will deliver faster and more efficient journeys, opening new possibilities for both business and leisure travel throughout the nation. Siemens Mobility: Revolutionizing rail travel in the UK With over 170 years of history in the UK, Siemens Mobility has been at the forefront of transforming rail, travel, and transport. Employing approximately 5,500 people across over 30 sites, including manufacturing facilities in Ashby-de-la-Zouch, Leicestershire; Chippenham, Wiltshire; and Goole, East Yorkshire, the company is deeply committed to supporting local economies. Innovation, sustainability, and efficiency Siemens Mobility pioneers in digital signaling technology and provides cutting-edge service solutions. In October, the company opened its €277 million Rail Village in Goole, a state-of-the-art facility dedicated to manufacturing Piccadilly line trains and future UK fleets. As a trusted partner, Siemens Mobility continues to drive innovation, sustainability, and efficiency across the UK’s transportation network.

The Westerscheldetunnel, a vital infrastructure asset managed by N.V. Westerscheldetunnel on behalf of the Province of Zeeland, is the longest tunnel in the Netherlands at 6.6 kilometers underwater. As a key transportation route, the tunnel ensures smooth connectivity between regions, making its uninterrupted operation critical. A power outage in such an environment could jeopardize the safety of travelers by disrupting critical systems, such as lighting, ventilation, and signaling. Industrial Power Transformer Delta addressed this vital need by installing state-of-the-art IPT-50kVA Industrial Power Transformer Ensuring these systems remain operational, even during power disruptions, is essential to safeguard the lives of those driving through the tunnel. Delta addressed this vital need by installing state-of-the-art IPT-50kVA Industrial Power Transformer-based UPS systems, showcasing its expertise in delivering comprehensive turnkey solutions for industrial environments. Innovative Tailored Power Solutions The UPS system previously used in the Westerscheldetunnel had reached the end of its lifespan and needed to be replaced. The complex logistics of installing a new system within the tunnel presented significant challenges. To address these issues, a solution was needed that could ensure reliable power delivery while optimizing space and operational efficiency. Inverter-integrated isolation transformers Delta supplied its newly launched IPT-50kVA UPS units, each with a compact footprint (600 x 830 x 1420 mm) To meet these requirements, Delta supplied its newly launched IPT-50kVA UPS units, each with a compact footprint (600 x 830 x 1420 mm), making them ideal for installations where space is limited. These systems feature advanced technologies, including IGBT rectifiers for low total harmonic distortion (iTHD <3%) and inverter-integrated isolation transformers, enhancing short-circuit capability and load separation. These innovations provided a reliable and manageable power solution that directly addressed the tunnel’s requirements. Efficient Implementation in a Record Time Frame In December 2023, Croonwolter&dros, acting on behalf of N.V. Westerscheldetunnel, partnered with e-Power to implement Delta's IPT-50kVA systems during the second phase of the project. Delta’s product management and engineering teams collaborated closely with e-Power to deliver the UPS systems on a tight schedule, meeting the demanding deadline. Tunnel's operational efficiency The new systems have significantly enhanced the tunnel's operational efficiency The new systems have significantly enhanced the tunnel's operational efficiency. Features such as a user-friendly 10-inch waterproof touch panel and advanced event analysis capabilities have reduced maintenance time and costs. Additionally, the compact design also streamlined installation, optimizing project and labor management. Ensuring Safety Through Reliable Power The reliability of the IPT-50kVA UPS systems plays a critical role in ensuring safety within the Westerscheldetunnel. These systems provide seamless backup power, ensuring that essential functions like signaling, ventilation, and lighting remain operational even during power outages. Such redundancy is vital to maintain visibility, air quality, and clear communication within the tunnel, preventing accidents and ensuring the safety of the traffic going through the tunnel. Westerscheldetunnel's power infrastructure The reliability of the IPT-50kVA UPS systems plays a vital role in ensuring the safetyMr. Leon van der Kraan, Procurement Manager at Croonwolter&dros, remarked: “The collaboration between Delta, e-Power, and Croonwolter&dros has been vital in the successful upgrade of the Westerscheldetunnel's power infrastructure." "Delta's innovative IPT-50kVA UPS systems have met our stringent requirements, ensuring reliable and efficient tunnel operations that prioritize the traffics safety.” Overcoming Challenges with Strategic Collaboration Delta's partnership with e-Power ensured efficient handling of logistics, installation, commissioning, and ongoing service, adhering to Croonwolter&dros' high standards for reliability and performance. This collaboration effectively addressed logistical challenges, including extended sea freight times from Delta’s overseas factory to Europe. Data center solutions Delta's partnership with e-Power ensured efficient handling of logistics, installation, commissioning Mandy Ho, Sales Manager, Data Center Segment, Delta EMEA, added: “Our IPT-50kVA systems’ compact footprint and robust features provided the perfect solution for N.V. Westerscheldetunnel’s needs." "The successful delivery and installation by our premium partner e-Power further cement Delta’s position as a pioneering provider of containerized data center solutions.” Innovative IPT-50kVA systems Arnoud Blijleven, Technical Director at e-Power, emphasized: “The innovative IPT-50kVA systems have exceeded our expectations in terms of performance and reliability." "This project exemplifies the strength of our partnership and our combined ability to deliver outstanding solutions for critical infrastructure.” A Successful Partnership and Future Prospects The Westerscheldetunnel project marks the first successful implementation of Delta’s IPT UPS solutions in the Netherlands. Delta's proven track record, supported by dependable partnerships with Croonwolter&dros and e-Power, has positioned Delta as a pioneering provider of UPS systems in critical infrastructure. This project highlights Delta’s and its partners’ ability to deliver high-quality, turnkey solutions that meet stringent requirements. Delta looks forward to leveraging this success in future projects, applying the valuable experience gained to continue offering innovative and reliable solutions to its clients.

Mitsubishi Electric Corporation announced that its wholly owned subsidiary, Mitsubishi Electric India Pvt Ltd., will acquire a stake in Indian software startup Gervigreind Data Science Pvt. Ltd. (doing business as "Itanta Analytics") to jointly develop and sell no-code data analysis and report generation applications. Under a collaboration agreement, Mitsubishi Electric plans to strengthen its FA digital solutions business and contribute to the digitalization of manufacturing sites by combining its factory automation (FA) equipment and FA solution software with its new partner's cost- and time-saving applications. SCADA software Specifically, the applications will be combined with Mitsubishi Electric's FA equipment and GENESIS64TM, a supervisory control and data acquisition (SCADA) software developed by ICONICS, Inc., a wholly owned U.S. subsidiary of Mitsubishi Electric. The goal is to realize digital solutions using systems developed through simple no-code engineering. Leveraging its partner's extensive application expertise, Mitsubishi Electric plans to further grow its FA digital solutions business globally. Digital technology and data FA systems business is investing in and cooperating with software companies to strengthen automation As Mitsubishi Electric strives to accelerate its transformation into a "Circular Digital-Engineering" company, its FA systems business is investing in and cooperating with software companies to strengthen automation and digitalization in diverse manufacturing processes, including design, manufacturing, testing, operation, and maintenance, ultimately to provide customers with best-in-class products and solutions. In recent years, the manufacturing sector has faced challenges such as rising capital and labor costs, diversifying customer needs, and the need for further productivity improvements. In response, manufacturers are increasingly using digital technology and data. work efficiency In particular, to reduce labor-intensive system-construction tasks and time, manufacturers are seeking development environments that are easy to build and do not require complex programming. In India, where manufacturers are experiencing high growth supported by government policies, but also rising labor costs and a shortage of available labor, there is a strong demand for software, such as data analysis tools, which can be easily implemented to improve work efficiency. open innovation Going forward, Mitsubishi Electric is committed to promoting open innovation by collaborating with innovative companies and cutting-edge technologies. Through diverse partnerships, the company is pursuing powerful solutions and continuous advancement to address the challenges faced by manufacturers.

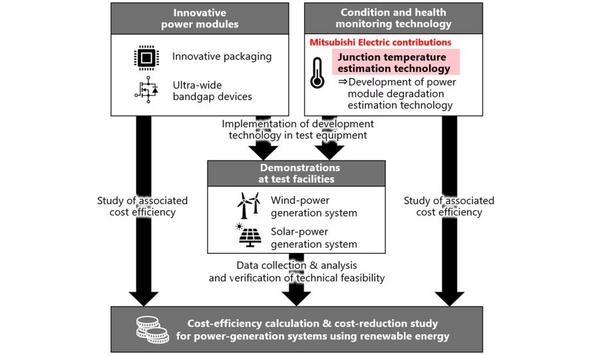

Mitsubishi Electric Corporation announced that it will begin developing a prototype to demonstrate a junction-temperature estimation technology for power modules. The company is pursuing this technology as a partner in the European Union's Horizon Europe project, which aims to develop advanced power modules and improve the cost efficiency of renewable energy power generation. The company is participating through its European subsidiary Mitsubishi Electric R&D Centre Europe B.V., which has joined the project, called Flagship Advanced Solutions for Condition and Health Monitoring in Power Electronics (FLAGCHIP). reliability and maintenance The need to upgrade the reliability and maintenance of electronic devices for power conversion has become increasingly important in the global effort to expand the introduction of renewable energy to support carbon neutrality. Attention is being focused on technological innovations that aim to strengthen power module reliability and improve data acquisition and analysis methods. These innovations aim to accurately determine degradation conditions and facilitate more timely maintenance. cost efficiency Wind-power and solar-power generation systems will be demonstrated using these technologies The FLAGCHIP project currently involves 11 companies and academic institutions from nine European countries engaged in developing advanced power modules, condition and health monitoring technologies, and devising methods for calculating the cost efficiency of renewable-energy power-generation systems and reducing associated costs. Wind-power and solar-power generation systems will be demonstrated using these technologies and methods at test facilities owned by project partners in Norway and France. estimating module degradation Mitsubishi Electric will be in charge of demonstrating a technology that estimates the junction temperature of silicon carbide metal-oxide-semiconductor field-effect transistor (SiC-MOSFET) semiconductor chips inside the power module, which will provide necessary data for accurately estimating module degradation. Starting in October 2026, the demonstration will use the newly developed prototype at a test facility in France where direct current (DC) voltage is converted to a specific DC voltage for a wind-power generation system.

The Via Inspirada Center for Excellence (VICE), an endeavor by the City of Henderson, is set to become a nexus of education and training. Throughout the construction process, GSL Electric played a pivotal role in delivering an exceptional electrical installation. Let's delve into the details of the contributions the GSL Electric team brought to the VICE project. Navigating unique challenges GSL Electric's skilled team came these challenges head-on, turning the hurdles into opportunities Every project presents its unique set of challenges, and VICE was no exception. With a significant portion of the building constructed using block material and an owner's emphasis on concealed conduits, the routing and installation of the electrical system demanded meticulous planning and execution. GSL Electric's skilled team approached these challenges head-on, turning the hurdles into opportunities for creativity and innovation. Their expertise and attention to detail ensured a seamless integration of the electrical system within the architectural framework, resulting in a remarkable outcome. Exceeding expectations The Via Inspirada Center for Excellence spans an impressive 17,000 square feet, and hosts a state-of-the-art advanced manufacturing training program, a public art gallery, and the city's economic development department. GSL Electric, with an average crew size of only three field electricians, invested a total of 4,626.5 labor hours into this transformative project. Their combined decades of experience were the key to delivering superior results thoughout every step of the construction process. Electrical specs GSL Electric ensured that every wire, every link, and every part adhered to the highest industry norms Under GSL Electric's expert guidance, the electrical system at VICE stands as a testament to their technical prowess and commitment to excellence. The installation involved a staggering 32,175 linear feet of electrical cable and 30,592 feet of conduit. The electrical service installed, a 1200A 277/480V 3 phase, 4W, 42K AIC, provides a robust and reliable power supply to support the facility's diverse needs. With precision and care, GSL Electric ensured that every wire, every connection, and every component adhered to the highest industry standards, guaranteeing the safety and efficiency of the electrical infrastructure. A culture of safety At GSL Electric, safety is not just a priority; it is ingrained in every aspect of their work. The Via Inspirada Center for Excellence project is a shining example of GSL Electric's unwavering commitment to safety. Throughout the entire project duration, not a single OSHA injury was reported, demonstrating GSL Electric's dedication to maintaining a safety-first culture. Field leaders and the entire GSL Electric team worked diligently to ensure a safe working environment for everyone involved. Celebrating team excellence Jerry and Omar exhibited exemplary workmanship, dedication, and unwavering commitment While the success of the Via Inspirada project can be attributed to the collective efforts of the entire GSL Electric team, special recognition is due to two exceptional individuals: Jerry Tewes and Omar Perez. From the project's inception to its completion, Jerry and Omar exhibited exemplary workmanship, dedication, and unwavering commitment. Their contributions were invaluable, and their attention to detail helped achieve outstanding results. Unwavering commitment to safety The Via Inspirada Center for Excellence stands as a testament to the power of collaboration, innovation, and meticulous craftsmanship. It would not have been possible without a team dedicated to bringing their best to the project. Their ability to overcome unique challenges, deliver exceptional electrical construction, and maintain an unwavering commitment to safety demonstrates their expertise and professionalism.

Siemens eMobility has been selected as the technology partner for two major electric vehicle (EV) charging infrastructure projects in Italy. Partnering with Autolinee Toscane and IPLANET, Siemens eMobility is driving the electrification of public transportation and the transformation of petrol stations into strategic service areas, further advancing sustainable mobility in the region. Siemens’ innovative technology Siemens eMobility is electrifying multiple bus depots for Autolinee Toscane Siemens eMobility is electrifying multiple bus depots for Autolinee Toscane, a major public transport operator and part of RATP DEV Italia Group, in the cities of Florence, Prato, and Lucca, supporting the rollout of the company’s zero-emission bus fleet. Leveraging Siemens’ innovative charging infrastructure technology, this project ensures efficient and reliable operations across Tuscany’s public transport network. 73 charging points for Autolinee Toscane S.p.A. The project consists of a total of 73 SICHARGE UC charging points, capable of supplying 100 and 150 KW of power to charge electric vehicles. In addition, Siemens supplies medium and low-voltage electrical distribution systems with switches equipped with IoT modules to ensure a reliable and transparent energy supply. Siemens eMobility also provides DepotFinity, a software platform for monitoring, reporting, programming and managing charging operations within the depots. The main benefits for Autolinee Toscane are the monitoring of charging processes with the implementation of optimized smart charging logics of loads based on the operator's service, pre-conditioning functionality of vehicle batteries and reporting of the kilometers traveled by each individual vehicle. Advanced charging infrastructure for 120 IPLANET service sites In another project, IPLANET, a renowned energy transition solutions provider, has tasked Siemens eMobility with equipping over 120 logistics sites with advanced charging infrastructure, featuring integrated Point of Sales (POS) systems compliant with Alternative Fuels Infrastructure Regulation (AFIR), activation via app or QR code, and interactive screens ensuring accessibility also for users with disabilities. The network includes hundreds of 300-400 kW charging points, all fully remotely monitored through independent connectivity channels to ensure high reliability and availability. Integration with renewable energy sources The sites also incorporate Siemens medium and low voltage electrical distribution systems The sites also incorporate Siemens medium and low voltage electrical distribution systems, scalable compact transformer substations, and telecontrol capabilities, enabling integration with renewable energy sources. Additionally, some of the turnkey service areas, including photovoltaic installations, parking area battery energy storage systems (BESS), and facilities for heavy-duty EV charging (e-trucks), are already operational. Driving sustainable mobility together "Projects like these underscore Siemens eMobility’s mission to integrate sustainable mobility into everyday life. By combining cutting-edge technology and strong partnerships, we’re helping to transform the transportation and logistics sectors for a more sustainable future," said Markus Mildner, CEO of Siemens eMobility. Siemens eMobility’s portfolio spans IoT-connected hardware, software, and services for both AC and DC charging, supporting applications from 11 kW to 1 MW. With a strong focus on the fast-growing eBus and eTruck market, the company continues to lead the way in providing comprehensive solutions tailored to diverse customer needs. impactful eMobility solutions With over 100,000 charging points installed and 800 projects completed in more than 60 countries, Siemens eMobility combines global expertise with local execution. The partnerships with Autolinee Toscane and IPLANET reaffirm its commitment to innovation, collaboration, and sustainability in delivering impactful eMobility solutions.

Siemens Mobility has been awarded four significant contracts by HS2 Ltd and will join key contractors under the Rail Systems Alliance. Siemens Mobility will play a crucial role in the delivery and operation of the new 225-kilometer-long British high-speed railway that will connect London and the West Midlands. Capacity and energy efficiency For the first time, Siemens Mobility will implement wayside Automatic Train Operations [ATO] over the European Train Control System [ETCS] Level 2 on a high-speed network, enabling semi-automatic train operations (Grade of Automation 2) for improved capacity, punctuality, and energy efficiency. Another contract focuses on an Engineering Management System that will enable real-time control and monitoring of railway equipment, ultimately enhancing reliability and efficiency. high-voltage power supply All awarded contracts are expected to commence in 2025 with a total order value of approximately 670 million Euros Siemens Mobility also formed a joint venture with Costain Ltd to deliver high-voltage power supply systems along the HS2 route. Finally, Siemens Mobility will take charge of implementing Operational Telecommunications and Security Systems for the entire HS2 route. All awarded contracts are expected to commence in 2025 with a total order value of approximately 670 million Euros, including long-term maintenance agreements, and potentially including additional options. electrification technology “HS2 is set to transform rail travel by offering faster and more reliable passenger journeys and freeing up freight paths in the UK. We are very proud to provide our wayside ATO over ETCS solution, enabling semi-automated train operations for improved capacity, punctuality, and energy efficiency on high-speed travel for the first time. Furthermore, we will deliver cutting-edge electrification technology and maintenance support for this groundbreaking project," said Michael Peter, CEO of Siemens Mobility. “HS2 will play a vital role in connecting the UK’s two largest cities and driving growth and sustainability nationwide. With our 5,500 UK employees, Siemens Mobility is fully committed to delivering advanced transportation solutions designed and built in Britain.” Command, Control, Signaling & Traffic Management [CCS&TM] Siemens Mobility will design, manufacture, supply, install, supervise, inspect, safety authorize, test, commission, and maintain a state-of-the-art European Train Control System [ETCS] Level 2 signaling system and traffic management solution with wayside Automatic Train Operation at GoA2. This solution will eliminate the need for traditional signals along the tracks by providing digital signaling Building on Siemens Mobility's successful signaling technology implemented in projects like Thameslink and the East Coast Digital Programme, this solution will eliminate the need for traditional signals along the tracks by providing digital signaling that feeds information directly to the train driver via a screen in their cab. This will improve operations and substantially simplify maintenance compared to conventional train control systems. Siemens Mobility will provide technical support services for the system for at least 15 years. Engineering Management System Siemens Mobility will design, manufacture, supply, install, integrate, test, commission, and maintain an integrated Supervisory Control and Data Acquisition [SCADA] system that will enable real-time control and monitoring of railway equipment, ultimately enhancing reliability and efficiency, utilizing the company's technology and provision of maintenance and technical support. Siemens Mobility will leverage its 50 years of experience in delivering advanced SCADA systems from projects such as the Elizabeth Line in London. Siemens Mobility will provide technical support services for the system for at least 15 years. High voltage [HV] power supply systems As part of the construction of HS2, traction and non-traction substations will be built alongside the railway line A Siemens Mobility and Costain joint venture will design, manufacture, supply, install, test, commission, and maintain a high-voltage power supply system for the HS2 high-speed rail project. As part of the construction of HS2, traction and non-traction substations will be built alongside the railway line. These sub-stations will play a critical role in facilitating the delivery of power from the National Grid to high-speed trains and other railway systems, ensuring their efficient and reliable operation. Siemens Mobility and Costain will provide maintenance services for the system for at least seven years. Operational Telecommunications and Security Systems Siemens Mobility will design, manufacture, supply, install, safety authorize, test, commission, and maintain an Operational Telecommunications and Security System along the HS2 route. This will provide Global System for Mobile Communications-Railway [GSM-R] secure, digital, wireless communications between drivers along the route. Passive provision will be made for an upgrade to the Future Railway Mobile Communication System [FRMCS]. The company will provide technical support services for the system for at least eight years. HS2: Set to transform rail travel in Britain As Britain's second purpose-built high-speed railway, HS2 follows in the footsteps of High Speed 1 HS2, the new high-speed railway currently being constructed, is set to transform Britain’s transportation landscape. Spanning 225 kilometers, the line will connect London to Birmingham with a spur to Handsacre, connecting HS2 trains to other UK cities in the North West and beyond. As Britain's second purpose-built high-speed railway, HS2 follows in the footsteps of High Speed 1, which links London to the Channel Tunnel. HS2 will deliver faster and more efficient journeys, opening new possibilities for both business and leisure travel throughout the nation. Siemens Mobility: Revolutionizing rail travel in the UK With over 170 years of history in the UK, Siemens Mobility has been at the forefront of transforming rail, travel, and transport. Employing approximately 5,500 people across over 30 sites, including manufacturing facilities in Ashby-de-la-Zouch, Leicestershire; Chippenham, Wiltshire; and Goole, East Yorkshire, the company is deeply committed to supporting local economies. Innovation, sustainability, and efficiency Siemens Mobility pioneers in digital signaling technology and provides cutting-edge service solutions. In October, the company opened its €277 million Rail Village in Goole, a state-of-the-art facility dedicated to manufacturing Piccadilly line trains and future UK fleets. As a trusted partner, Siemens Mobility continues to drive innovation, sustainability, and efficiency across the UK’s transportation network.

The Westerscheldetunnel, a vital infrastructure asset managed by N.V. Westerscheldetunnel on behalf of the Province of Zeeland, is the longest tunnel in the Netherlands at 6.6 kilometers underwater. As a key transportation route, the tunnel ensures smooth connectivity between regions, making its uninterrupted operation critical. A power outage in such an environment could jeopardize the safety of travelers by disrupting critical systems, such as lighting, ventilation, and signaling. Industrial Power Transformer Delta addressed this vital need by installing state-of-the-art IPT-50kVA Industrial Power Transformer Ensuring these systems remain operational, even during power disruptions, is essential to safeguard the lives of those driving through the tunnel. Delta addressed this vital need by installing state-of-the-art IPT-50kVA Industrial Power Transformer-based UPS systems, showcasing its expertise in delivering comprehensive turnkey solutions for industrial environments. Innovative Tailored Power Solutions The UPS system previously used in the Westerscheldetunnel had reached the end of its lifespan and needed to be replaced. The complex logistics of installing a new system within the tunnel presented significant challenges. To address these issues, a solution was needed that could ensure reliable power delivery while optimizing space and operational efficiency. Inverter-integrated isolation transformers Delta supplied its newly launched IPT-50kVA UPS units, each with a compact footprint (600 x 830 x 1420 mm) To meet these requirements, Delta supplied its newly launched IPT-50kVA UPS units, each with a compact footprint (600 x 830 x 1420 mm), making them ideal for installations where space is limited. These systems feature advanced technologies, including IGBT rectifiers for low total harmonic distortion (iTHD <3%) and inverter-integrated isolation transformers, enhancing short-circuit capability and load separation. These innovations provided a reliable and manageable power solution that directly addressed the tunnel’s requirements. Efficient Implementation in a Record Time Frame In December 2023, Croonwolter&dros, acting on behalf of N.V. Westerscheldetunnel, partnered with e-Power to implement Delta's IPT-50kVA systems during the second phase of the project. Delta’s product management and engineering teams collaborated closely with e-Power to deliver the UPS systems on a tight schedule, meeting the demanding deadline. Tunnel's operational efficiency The new systems have significantly enhanced the tunnel's operational efficiency The new systems have significantly enhanced the tunnel's operational efficiency. Features such as a user-friendly 10-inch waterproof touch panel and advanced event analysis capabilities have reduced maintenance time and costs. Additionally, the compact design also streamlined installation, optimizing project and labor management. Ensuring Safety Through Reliable Power The reliability of the IPT-50kVA UPS systems plays a critical role in ensuring safety within the Westerscheldetunnel. These systems provide seamless backup power, ensuring that essential functions like signaling, ventilation, and lighting remain operational even during power outages. Such redundancy is vital to maintain visibility, air quality, and clear communication within the tunnel, preventing accidents and ensuring the safety of the traffic going through the tunnel. Westerscheldetunnel's power infrastructure The reliability of the IPT-50kVA UPS systems plays a vital role in ensuring the safetyMr. Leon van der Kraan, Procurement Manager at Croonwolter&dros, remarked: “The collaboration between Delta, e-Power, and Croonwolter&dros has been vital in the successful upgrade of the Westerscheldetunnel's power infrastructure." "Delta's innovative IPT-50kVA UPS systems have met our stringent requirements, ensuring reliable and efficient tunnel operations that prioritize the traffics safety.” Overcoming Challenges with Strategic Collaboration Delta's partnership with e-Power ensured efficient handling of logistics, installation, commissioning, and ongoing service, adhering to Croonwolter&dros' high standards for reliability and performance. This collaboration effectively addressed logistical challenges, including extended sea freight times from Delta’s overseas factory to Europe. Data center solutions Delta's partnership with e-Power ensured efficient handling of logistics, installation, commissioning Mandy Ho, Sales Manager, Data Center Segment, Delta EMEA, added: “Our IPT-50kVA systems’ compact footprint and robust features provided the perfect solution for N.V. Westerscheldetunnel’s needs." "The successful delivery and installation by our premium partner e-Power further cement Delta’s position as a pioneering provider of containerized data center solutions.” Innovative IPT-50kVA systems Arnoud Blijleven, Technical Director at e-Power, emphasized: “The innovative IPT-50kVA systems have exceeded our expectations in terms of performance and reliability." "This project exemplifies the strength of our partnership and our combined ability to deliver outstanding solutions for critical infrastructure.” A Successful Partnership and Future Prospects The Westerscheldetunnel project marks the first successful implementation of Delta’s IPT UPS solutions in the Netherlands. Delta's proven track record, supported by dependable partnerships with Croonwolter&dros and e-Power, has positioned Delta as a pioneering provider of UPS systems in critical infrastructure. This project highlights Delta’s and its partners’ ability to deliver high-quality, turnkey solutions that meet stringent requirements. Delta looks forward to leveraging this success in future projects, applying the valuable experience gained to continue offering innovative and reliable solutions to its clients.

Mitsubishi Electric Corporation announced that its wholly owned subsidiary, Mitsubishi Electric India Pvt Ltd., will acquire a stake in Indian software startup Gervigreind Data Science Pvt. Ltd. (doing business as "Itanta Analytics") to jointly develop and sell no-code data analysis and report generation applications. Under a collaboration agreement, Mitsubishi Electric plans to strengthen its FA digital solutions business and contribute to the digitalization of manufacturing sites by combining its factory automation (FA) equipment and FA solution software with its new partner's cost- and time-saving applications. SCADA software Specifically, the applications will be combined with Mitsubishi Electric's FA equipment and GENESIS64TM, a supervisory control and data acquisition (SCADA) software developed by ICONICS, Inc., a wholly owned U.S. subsidiary of Mitsubishi Electric. The goal is to realize digital solutions using systems developed through simple no-code engineering. Leveraging its partner's extensive application expertise, Mitsubishi Electric plans to further grow its FA digital solutions business globally. Digital technology and data FA systems business is investing in and cooperating with software companies to strengthen automation As Mitsubishi Electric strives to accelerate its transformation into a "Circular Digital-Engineering" company, its FA systems business is investing in and cooperating with software companies to strengthen automation and digitalization in diverse manufacturing processes, including design, manufacturing, testing, operation, and maintenance, ultimately to provide customers with best-in-class products and solutions. In recent years, the manufacturing sector has faced challenges such as rising capital and labor costs, diversifying customer needs, and the need for further productivity improvements. In response, manufacturers are increasingly using digital technology and data. work efficiency In particular, to reduce labor-intensive system-construction tasks and time, manufacturers are seeking development environments that are easy to build and do not require complex programming. In India, where manufacturers are experiencing high growth supported by government policies, but also rising labor costs and a shortage of available labor, there is a strong demand for software, such as data analysis tools, which can be easily implemented to improve work efficiency. open innovation Going forward, Mitsubishi Electric is committed to promoting open innovation by collaborating with innovative companies and cutting-edge technologies. Through diverse partnerships, the company is pursuing powerful solutions and continuous advancement to address the challenges faced by manufacturers.

Mitsubishi Electric Corporation announced that it will begin developing a prototype to demonstrate a junction-temperature estimation technology for power modules. The company is pursuing this technology as a partner in the European Union's Horizon Europe project, which aims to develop advanced power modules and improve the cost efficiency of renewable energy power generation. The company is participating through its European subsidiary Mitsubishi Electric R&D Centre Europe B.V., which has joined the project, called Flagship Advanced Solutions for Condition and Health Monitoring in Power Electronics (FLAGCHIP). reliability and maintenance The need to upgrade the reliability and maintenance of electronic devices for power conversion has become increasingly important in the global effort to expand the introduction of renewable energy to support carbon neutrality. Attention is being focused on technological innovations that aim to strengthen power module reliability and improve data acquisition and analysis methods. These innovations aim to accurately determine degradation conditions and facilitate more timely maintenance. cost efficiency Wind-power and solar-power generation systems will be demonstrated using these technologies The FLAGCHIP project currently involves 11 companies and academic institutions from nine European countries engaged in developing advanced power modules, condition and health monitoring technologies, and devising methods for calculating the cost efficiency of renewable-energy power-generation systems and reducing associated costs. Wind-power and solar-power generation systems will be demonstrated using these technologies and methods at test facilities owned by project partners in Norway and France. estimating module degradation Mitsubishi Electric will be in charge of demonstrating a technology that estimates the junction temperature of silicon carbide metal-oxide-semiconductor field-effect transistor (SiC-MOSFET) semiconductor chips inside the power module, which will provide necessary data for accurately estimating module degradation. Starting in October 2026, the demonstration will use the newly developed prototype at a test facility in France where direct current (DC) voltage is converted to a specific DC voltage for a wind-power generation system.

Expert Commentary

The promise of electric vehicles is closer to reality than ever before. New plans and investments at the federal level designate billions of dollars to move our country toward clean energy, including $2 million to help auto manufacturers retool facilities to increase EV production. Additionally, the Biden Administration has announced a goal to create 100% carbon-free electricity by 2035 and a net-zero carbon economy by 2050. Domestic EV marketplace The domestic EV marketplace has grown from 16,000 to more than 2 million vehicles in the last decade and is poised to expand at lightning speed over the next ten years. S&P Global mobility has predicted that by 2030, electric vehicles (EVs) will make up 40% of the U.S. market share of new vehicles on the road. This dramatic increase in EVs will require a nationwide network of charging stations to meet the demand from the current 140,000 to over 1.1 million. Charging stations It is a necessity that regulators lay the groundwork now for a reliable and secure charging networkThe expansion of charging stations will undoubtedly give zero-emissions drivers more confidence in their ability to refuel more conveniently. Still, it’s critical that confidence in infrastructure security also be prioritized alongside this growth. If not adequately protected and monitored, charging stations could serve as access points for cybercriminals, potentially leading to personal data leaks, attacks on vehicle systems, and even widespread blackouts. As EVs continue to gain momentum as realistic alternatives to CO-2 emitting vehicles, it is a necessity that developers and regulators lay the groundwork now for a reliable and secure charging network for the long term. EV Charging Infrastructure and the electric grid The nation’s electric grid generates and delivers electricity essential to everyday life. It’s made up of power plants and other sources of generated electricity, complete with transmission and distribution lines and infrastructure that delivers essential power. Grid connection An important aspect to remember about EV charging stations is that they connect to their relative electric grid. Simply put, the infrastructure for charging stations is comprised of devices that wait for another device to connect and communicate. However, it lacks a third-party firewall or other devices that can act as protection. Unfortunately, this results in vulnerability and means new doors for cybercriminals to walk through. Cybersecurity risks If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts Even before EV charging stations are factored in, the electric grid faces substantial cybersecurity risks from criminals, terrorists, hackers, and foreign governments every day. If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts that would undoubtedly affect EV charging stations and other essential institutions such as banks, hospitals, and gas stations. With the expansion of EV charging stations, the risks only grow. Now is the time to address threats and strategize before disaster strikes. Risks of connectivity emerge The world we live in has reached a level of being almost entirely connected at all times – security systems, appliances, health monitors, industrial sensors, and now, our vehicles. While the connectivity of vehicles has been incredibly beneficial to consumers and the automotive industry alike, the growth in the internet of things (IoT) has opened countless doorways for cybersecurity threats. Software flaws One young information technology security specialist reported finding flaws within a third-party software that a handful of leading EV manufacturers use. It gave him access to more than 25 EVs in at least 13 countries. The man, who stumbled on the findings in 2022, said he could remotely control some EV functions, including starting vehicles, unlocking windows and doors, disabling security systems, and turning on stereo systems and flashing headlights. The IT specialist said he could also tell if a person was in the vehicle. In a separate and concerning situation, a single compromised password led to a foreign-fronted cyberattack on a U.S.-based pipeline in 2021. It halted the fuel supply process on the east coast and cost the company $4.4 million in ransom money. Cyberattacks Thousands of charging stations are already in danger of being targeted by cybercriminals The point is that even massive and powerful companies can fall victim to cyberattacks. Even though cybersecurity is a critical issue for EV manufacturers, their systems are still vulnerable to hackers. Thousands of charging stations are already in danger of being targeted by cybercriminals, and as the number of stations grows, so too will the risk. The higher the number of entry points, the more opportunities hackers will see. If they can break into and gain access to even the most sophisticated EVs, it could be catastrophic. Ensuring security and reliability through proactivity Because charging stations are connected to the country’s primary grid, the entire infrastructure must be armed with the most aggressive security measures. The risks associated with modernized electric vehicles are not something that traditional automotive safety regulations and security standards properly cover. The complicated and rapid evolution of EVs is putting them at a heightened threat. When charging stations are connected to the electrical grid, it is imperative to ensure strong cybersecurity measures are in place to remain dependable and effective. Embedding cybersecurity technology We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection The best way to ensure the electric grid's safety is to build cybersecurity technology directly into the charging stations. We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection. Unfortunately, the promising growth EVs and their charging stations bring to our environment also contributes to technology’s vulnerabilities, which can cause key security measures to be overlooked. There’s no getting around it: EV charging stations are highly vulnerable to hackers. Awareness and solutions As the growth continues, there is an acute need for heightened awareness and solutions for the weaknesses associated with these charging stations. These solutions should consider everything from the charging points and devices to operators of the energy distribution networks and infrastructure providers. We must aim to implement advanced cybersecurity measures that will keep safe drivers and all the data that EVs contain.

Power Beat

Electricians play a pivotal role in preventing electrical fires by following safe practices during installations, repairs, and inspections. At a minimum, electricians should ensure all electrical wiring and components are installed according to current building codes and manufacturers' specifications. This includes using the right size wires for the amperage load, using approved materials, and properly securing all connections. During electrical inspections, electricians should identify and address any potential fire hazards. Electricians can also advise homeowners on electrical safety measures they can take to prevent fires. These include safe appliance use, avoiding overloaded outlets, and the importance of smoke detectors and fire extinguishers. Maintenance of electrical systems Ground Fault Circuit Interrupters (GFCIs) can prevent possible fires. GFCI outlets have built-in protection to detect imbalances in electrical current and quickly shut off power to prevent shocks and potential fires, particularly in areas prone to moisture like kitchens and bathrooms. Regular maintenance of electrical systems is also crucial for fire prevention. Electricians can perform preventative maintenance checks to identify and address any developing issues before they become serious fire hazards. Fire departments responded to an average of 32,160 home fires involving electrical distribution Fire departments responded to an average of 32,160 home fires involving electrical distribution and lighting equipment each year in 2015–2019, according to the National Fire Protection Association (NFPA). Electrical fires cause scores of civilian deaths and hundreds of civilian injuries, as well as millions of dollars in property damage. Fire Hazards in the Home Some of the electrical components that present fire hazards in the home include faulty electrical outlets and switches, worn or damaged components, overloaded circuits, damaged or frayed cords, and misused extension cords and power strips. Improper use of light fixtures can also be a danger, and space heaters can be a fire hazard if they are placed too close to flammable materials or left unattended. Damaged or frayed cords can cause sparks and ignite nearby flammable materials As outlets and switches age, the wiring behind them can loosen and break, causing sparks and fire. Loose plugs can also overheat and ignite surrounding materials. Plugging too many appliances into a single outlet or using extension cords instead of proper wiring can overload a circuit, thus causing overheating and fires. Damaged or frayed cords can cause sparks and ignite nearby flammable materials. Cords that are kinked, pinched, or have exposed wires should be avoided and replaced immediately. Minimizing the Risk of Electrical Fires Here are some steps a homeowner can take to minimize the risk of fire from electrical systems: Upgrade the electrical system, especially if the home is older. If the electrical system has not been updated in a while, a qualified electrician can advise if it needs modernization. This could involve upgrading to breakers with better safety features such as Arc-Fault Circuit Interrupter (AFCI) and Ground Fault Circuit Interrupter (GFCI) technology. Schedule an electrical safety inspection. Having a qualified electrician periodically inspect a home's electrical system can identify potential problems before they escalate into fire hazards. Keep flammable materials away from electrical components, including curtains, furniture, and piles of paper. Sparks and overheating can easily ignite nearby flammables. Addressing Multiple Threats Effective communication is key for electricians to impress upon homeowners the seriousness of fire hazards. Avoid technical jargon and explain fire hazards in clear, concise language that homeowners can understand. Focus on the potential consequences, like damage to property or injury, to heighten awareness. Pictures can be worth a thousand words. Show homeowners examples of damaged wiring, overloaded outlets, or faulty installations that pose fire risks. This can be done through photos on a tablet or phone, or even carrying around small physical samples. Frame the conversation around safety for the homeowner and their family. Highlight how addressing these hazards can prevent potential fires and ensure a safe living environment. Provide a written report after the inspection or repair. This report should detail the identified hazards, the corrective actions taken, and any recommendations for future maintenance or upgrades. By combining clear communication, visual aids, and a focus on safety, electricians can effectively convey the importance of addressing fire hazards to homeowners and empower them to make informed decisions about their electrical systems.

Many economists are predicting a recession in 2023, although most agree business conditions should improve by the end of the year. For the electricals market, numerous factors are in play that can offset the downturn, and any projections must also consider the variables of the local market (rather than the national or international outlook). Economic weakness and challenges The Conference Board forecasts that economic weakness will intensify and spread more widely throughout the U.S. economy over the coming months with a recession starting in early 2023. Real GDP growth was expected to be 2.0 percent year-over-year in 2022, then slow to 0.2 percent in 2023, and later rebound to 1.7 percent in 2024, according to the Conference Board. 2023 comes on the heels of a challenging year for electricals, when price increases and product shortages were a stark reality. Impact of higher prices A troubled geopolitical environment provides an additional source of economic uncertainty Sales growth numbers in 2022 were skewed by the impact of inflation: How much of the bigger numbers were “real growth” and how much reflected the impact of higher prices? Higher prices accounted for the lion’s share of revenue growth by some estimates, with real growth in the low single digits. A troubled geopolitical environment, exemplified by the war in Ukraine and a continuing COVID crisis in China, provides an additional source of economic uncertainty. environmentally friendly technologies A positive factor that may offset the fragile outlook in 2023 includes an overall trend toward greater electrification and away from less energy-efficient power sources. Governments around the world are pushing for more environmentally friendly technologies, which provides positive headwinds for the electricals market. In the United States, for example, the Inflation Reduction Act, passed in August 2022, includes government investments and tax incentives to drive the transition to a greener world, including $27 billion to deploy low- and zero-emissions technologies, and $1 billion more each for advancing zero-emissions heavy-duty vehicles and for zero-energy building code adoption. Tax incentives Another $750 million will be spent to establish interstate electricity transmission lines, and $87 million will go to low-emission electricity programs. Tax incentives will provide new inducements for consumers to transition to electric technologies, which means more business for the broader electrical market. The government is also encouraging investment in infrastructure spending and the construction of factories for a variety of electrical products. Residential construction The higher interest rates present affordability challenges for home buyers and a slowdown in the market Residential construction, a big factor in the electricals outlook, has slowed down considerably in 2022, and the trend will likely continue into 2023. The U.S. Federal Reserve has raised interest rates by a total of 4.25 percentage points in 2022, a trend that is reflected in the interest rates charged to homebuyers. Mortgage rates for a 30-year fixed mortgage increased from 3.2% to 6.3% in 2022. The higher interest rates present affordability challenges for home buyers and a slowdown in the market for single-family construction. Markets in the Sunbelt are less affected, but data on housing starts and building permits nationwide reflect the slowdown. Non-residential construction Non-residential construction has held up well in 2022, but demand is weakening in the new year, while a backlog of projects will likely preclude the worst of the impact, although the business pipeline will eventually be depleted. A troubling long-term trend for the construction market, and by extension the electricals market, is the tendency of companies to allow employees to work from home at least part of the time. The apparent eventual consequence is to lower the demand for office space, already reflected in lower occupancy numbers in some markets. Less construction means less demand for electrical products and services. Obviously, the long-term trend lines are still uncertain. Supply chain woes Supply chain woes and longer lead times continued to plague the world market at the start of 2023, although the situation has improved since the worst of times. Lead times are still months longer than normal, and products powered by semiconductor chips, such as lighting controls, are especially a challenge. An employee shortage continues as companies in all sectors of the electricals market struggle to find enough employees to fill their needs. The shortage stimulates opportunities for companies to work smarter and to provide more preassembled electrical products to simplify installation.

Case studies

WEG stands out once again by supplying a large custom-built induction motor for an Integrated Steel Plant in the Eastern part of India, in the state of Odisha. The induction motor of the MGW line, 26 MW/4 Poles/11 kV, is the largest ever manufactured in WEG's manufacturing site in India for the Indian market, it was selected to drive the main air compressor of the oxygen plant, essential for the operation of the entire Phase-1 of the steel production plant. challenges of interchangeability The project involved replacing an existing motor at the plant, a complex task that required technical expertise to overcome the challenges of interchangeability of the new motor with the existing structure. For this, it was essential to combine all the dimensions of the machine, ensuring that no modifications were necessary on-site or in the foundation. From the water inlet and outlet to the oil lines, cable entry points and shaft details, each element was carefully considered for an efficient transition. WEG supplies induction motor System criticality has been significantly minimized, eliminating the need for complex maintenance The choice of an induction motor not only met the technical demands, but also offered substantial advantages over synchronous motors, commonly used for this application because induction motors are rare in this size and power. System criticality has been significantly minimized, eliminating the need for complex maintenance associated with components such as the exciter and exciter panels, as well as delicate integration with motor and rotor telemetry systems. WEG's commitment The reliability of WEG's induction motor was a key element in keeping production running smoothly. Since the motor was installed, the steel plant has not experienced any unplanned downtime in the last one year of operation, contributing to a continuous and efficient production environment. With WEG's commitment to offer technological and reliable solutions to the market, this association not only increases the productivity of the plant, but also contributes to increasing the steel production capacity on Indian soil.

Oshkosh Airport Products, a division of Pierce Manufacturing Inc., a subsidiary of Oshkosh Corporation announces Airservices Australia has issued a purchase order for four Oshkosh Airport Products Striker® Volterra™ 6x6 Aircraft Rescue and Fire Fighting (ARFF) hybrid electric vehicles. These environmentally advanced fire apparatus will be deployed at the new Western Sydney International Airport (WSI), set to open in 2026. Striker Volterra 6x6 The Striker Volterra 6x6 comes equipped with an Oshkosh-patented hybrid-electric drivetrain, featuring an electro-mechanical infinitely variable transmission. This enables zero-emissions operation through the integrated onboard batteries and uninterrupted power supply by coupling with the internal combustion engine for pumping and drive systems. innovative design Airservices Australia is making a significant investment to support the development of an “airport of the future” WSI is a transformational infrastructure project expected to boost economic activity, provide local employment opportunities, meet Sydney's carbon-neutral sustainability initiatives, and meet the area’s growing aviation needs. Airservices Australia is a government entity making a significant investment to support the development of an “airport of the future,” featuring world-pioneering technology, innovative design, and a sustainability plan incorporating assets like the Striker Volterra ARFF hybrid electric vehicles. sustainability "As the first airport built in Australia in over 50 years, WSI is not just an airport; it's a statement of intent for a more sustainable future,” said Dave Archer, Vice President of Engineering for Oshkosh Vocational. He adds, “The Striker Volterra vehicles, with their hybrid electric technology, align perfectly with Airservices Australia and WSI’s goals. These vehicles are not only an asset to emergency response capabilities but also play a crucial role in larger environmental sustainability initiatives." environmentally conscious choice Dave Archer continues, "They symbolize a dedication to intelligent design, energy optimization, fire crew safety and efficiency, and ultimately, a carbon-neutral future." Striker Volterra ARFF hybrid electric vehicles demonstrate the most advanced acceleration and reduced fuel consumption compared to our standard diesel models, making them an environmentally conscious choice for emergency response services. Striker Volterra features Striker Volterra ARFF demonstrates a 28 percent improved acceleration compared to the standard diesel models WSI’s four new Striker Volterra 6x6 vehicles will feature an industry-pioneering modular cab design, TAK-4® all-wheel independent suspension, and a 50’ Snozzle® High Reach Extendable Turret. They each house an 11,356-liter (3,000-gallon) water tank, a 1,590-liter (420-gallon) foam tank, and a 7,570 lpm (2,000 gpm) water pump, along with a 250 kg (550 lb.) dry chemical powder system. Accelerating from 0 to 80 kph (0 to 50 mph) in under 25 seconds, the Striker Volterra ARFF demonstrates a 28 percent improved acceleration compared to the standard diesel models when fully loaded. training, implementation, and service support Dave Archer added, “The collaboration between Oshkosh Airport Products and Airservices Australia marks a significant step forward in the aviation industry's commitment to sustainability. We remain committed to a strong partnership, providing world-class training, seamless implementation, and unwavering service support to ensure these vehicles exceed expectations in the critical missions of ARFF crews.” By leveraging new technologies and innovations like Oshkosh Airport Products’ Striker Volterra ARFF hybrid electric vehicles, WSI will showcase the feasibility of low-carbon operations and set a new standard for airports worldwide.