HVAC

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, unveiled its broad spectrum of next-generation power and liquid cooling solutions at NVIDIA GTC 2025. These solutions are designed to bolster the performance and energy conservation in NVIDIA-enabled AI and HPC data centers, including the newly launched Power Capacitance Shelves and in-row 1.5MW liquid-to-liquid Coolant Distribution Units (CDU). NVIDIA Omniverse™ platform Delta’s AI-based Smart...

On June 17, 2022, the world's first 35kV high-voltage direct coupled energy storage system developed by NR was successfully connected to the grid in Shaoxing Hongxu energy storage power station in China. It not only helps to achieve the efficient use of clean energy and promote the green and low-carbon transformation, but also enhances the flexible regulation capacity of the power grid. High voltage direct coupled energy storage not only reduces the electrical distance from the main grid, but a...

Ameren Illinois proposed an ambitious plan to help its residential and business customers further reduce their energy usage, lower their carbon footprint, and save on their monthly energy bills. The plan submitted to the Illinois Commerce Commission targets 1,122 GWh of electric savings through energy efficiency upgrades from 2026 to 2029, which is expected to save customers over $2 billion over the life of the upgrades. Electric and gas efficiency programs Ameren Illinois will invest $1...

The Westerscheldetunnel, a vital infrastructure asset managed by N.V. Westerscheldetunnel on behalf of the Province of Zeeland, is the longest tunnel in the Netherlands at 6.6 kilometers underwater. As a key transportation route, the tunnel ensures smooth connectivity between regions, making its uninterrupted operation critical. A power outage in such an environment could jeopardize the safety of travelers by disrupting critical systems, such as lighting, ventilation, and signaling. Industrial...

Mitsubishi Electric Corporation announced that its wholly owned subsidiary, Mitsubishi Electric India Pvt Ltd., will acquire a stake in Indian software startup Gervigreind Data Science Pvt. Ltd. (doing business as "Itanta Analytics") to jointly develop and sell no-code data analysis and report generation applications. Under a collaboration agreement, Mitsubishi Electric plans to strengthen its FA digital solutions business and contribute to the digitalization of manufact...

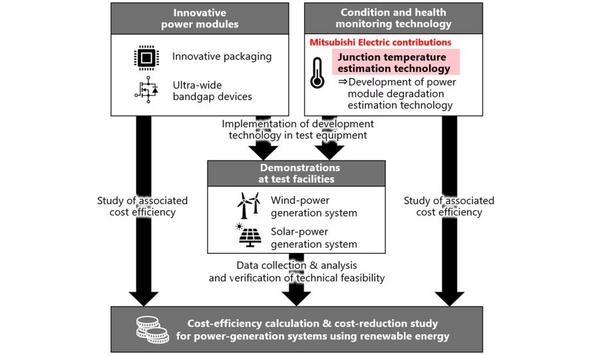

Mitsubishi Electric Corporation announced that it will begin developing a prototype to demonstrate a junction-temperature estimation technology for power modules. The company is pursuing this technology as a partner in the European Union's Horizon Europe project, which aims to develop advanced power modules and improve the cost efficiency of renewable energy power generation. The company is participating through its European subsidiary Mitsubishi Electric R&D Centre Europe B.V., which...

News

In the overhead crane market, precision and reliability are critical due to the demanding nature of heavy-duty applications. Overhead cranes require advanced motor control systems to ensure smooth, efficient, and safe operations, particularly in lifting and transporting heavy loads. The complexity of these operations demands high-performance drives that can manage constant torque, minimize load oscillations, and provide reliable braking sequences. Delta's innovative AC motor drive solutions Addressing these unique requirements, Delta's innovative AC motor drive solutions have been successfully adapted to enhance the performance and reliability of overhead crane solutions provided by Elektro-Mak Crane Systems Ltd., a manufacturer of overhead cranes in Turkey. This collaboration has showcased Delta's strong market position and demonstrated its commitment to enhancing operational efficiency in the crane industry. Enhancing operational efficiency Elektro-Mak Crane Systems Ltd. is renowned for its expertise in producing overhead cranes Established in 1989 in Izmir, Turkey, Elektro-Mak Crane Systems Ltd. is renowned for its expertise in producing overhead cranes with capacities ranging from 250 kg to 200 tons and bridge openings below 45 meters. Operating from a state-of-the-art plant in Manisa covering 6,000 m², Elektro-Mak is a prominent player in the Turkish crane market. The company's dedication to quality and innovation has positioned it as a trusted partner for heavy-duty crane solutions. Delta and Elektro-Mak partnership The collaboration between Delta and Elektro-Mak began with the goal of enhancing the performance of overhead cranes using Delta's advanced AC motor drives. Elektro-Mak adopted Delta's C2000+ AC Motor Drives for hoisting, ME300 AC Motor Drives for long travel, and trolley operations. These drives were selected for their high-level motor control performance, competitive pricing, and robust technical support. Overcoming tough environmental conditions Delta's AC motor drives were integrated into Elektro-Mak's overhead cranes, addressing the company's need for a cost-competitive solution with an anti-sway function using open-loop control. The entire testing and commissioning process, completed in just two days, required extensive support from Delta's R&D and product management teams, particularly for parameter adjustments and overcoming tough environmental conditions. The integration process faced challenges, particularly with the anti-sway function without an encoder. However, through persistent testing and parameterization on-site, Delta's team successfully implemented a solution that met Elektro-Mak's stringent requirements. Enhancing safety and operational efficiency The success story of Elektro-Mak underscores the importance of close collaboration The results of this collaboration were outstanding. Elektro-Mak experienced a significant improvement in crane performance, with the anti-sway function and reliable braking sequence enhancing safety and operational efficiency. The ease of integration and robust performance of Delta's AC motor drives allowed Elektro-Mak to meet its production goals effectively in less time. This project is a testament to Delta's commitment to providing innovative, cost-effective automation solutions tailored to meet specific customer needs. The success story of Elektro-Mak underscores the importance of close collaboration and a thorough understanding of customer requirements. Adopting cutting-edge technologies In the words of Martien Heesterbeek, Product Manager at Industrial Automation Business Group, Delta EMEA, "This project with Elektro-Mak not only showcases our capabilities in delivering advanced automation solutions but also reinforces our commitment to customer satisfaction and innovation. We are proud to have supported Elektro-Mak in achieving significant improvements in their production processes." Şükrü Terzi, General Manager at Elektro-Mak shared his thoughts on the collaboration: "Partnering with Delta has been a transformative experience for us. The integration of their AC motor drives into our crane systems has not only boosted our production reliability and efficiency but also underscored our commitment to adopting cutting-edge technologies. Delta’s support throughout the project has been excellent, and we look forward to continuing this successful partnership." Advanced motor control systems Elektro-Mak has set a new benchmark in the overhead crane industry The collaboration between Delta and Elektro-Mak has set a new benchmark in the overhead crane industry, demonstrating the immense potential of integrating advanced motor control systems in industrial applications. As Delta continues to innovate and expand its product offerings, the company remains committed to providing reliable and efficient solutions, including both small and high-power AC drive that meet the evolving needs of the market. Leveraging Delta’s cutting-edge automation solutions Delta's unwavering dedication to problem-solving and customer support, combined with Elektro-Mak’s operational excellence and strategic insights, has forged a formidable partnership. This collaboration stands as a beacon of success in the automation industry, providing a model for others seeking superior solutions in overhead crane manufacturing. By leveraging Delta’s cutting-edge automation solutions, Elektro-Mak has set a new benchmark in the overhead crane industry, demonstrating the immense potential of integrating advanced motor control systems in industrial applications.

The Midcontinent Independent System Operator (MISO) has selected Ameren to build multiple critical energy infrastructure projects that will carry clean, reliable energy to distribution grids in Missouri, Illinois and several Midwest states. The projects, which MISO estimates will represent a total investment of approximately $1.3 billion, are part of a portfolio of energy infrastructure investments under MISO's Long-Range Transmission Plan. Strengthening the transmission system “As demand for reliable energy increases, it is imperative that we strengthen the transmission system to utilize diverse energy resources across the Midwest to support the needs of our residents and businesses,” said Shawn Schukar, Chairman and President of Ameren Transmission Company of Illinois, a subsidiary of Ameren Corporation (AEE). He adds, “The energy delivered by these projects will boost reliability and enable the bi-state region to compete for economic development opportunities, including the expansion and relocation of energy-intensive industries.” Ameren can get transmission systems energized faster Shawn Schukar continues, “Ameren can get these transmission systems energized faster and for less cost than other companies. We appreciate MISO's confidence in our team to take on these important projects.” Increasing access to diverse energy resources across the MISO footprint will ensure customer affordability The energy corridors identified in MISO’s Tranche 2.1 portfolio will work in conjunction with Ameren's current transmission system to enhance reliability and resiliency for customers, while supporting economic development. Increasing access to diverse energy resources across the MISO footprint will ensure customer affordability and access to clean energy for millions of people. Ameren to bid on Tranche 2.1 infrastructure projects Ameren plans to bid on other infrastructure projects in Tranche 2.1, where the company’s capabilities and current resources would enhance reliability, resiliency and affordability for customers. “While Ameren participated in the competitive bidding process for Tranche 1 and plans to do so again, we believe in establishing energy policy that allows the trusted local provider to develop these projects, reducing unnecessary costs and delivering value to the customers sooner,” said Shawn Schukar. He adds, “When we lead these critical projects, we finish them faster and maximize economic development.”

Siemens has installed and commissioned the world’s first 8DAB 24, the ground-breaking blue GIS medium-voltage system, in the Alpine town of Davos, Switzerland for its customer - EWD Elektrizitätswerk Davos AG. The switchgear system, which uses Clean Air as insulating gas instead of sulfur hexafluoride (SF6), is deployed in the Dorf substation in Davos, securing reliable power supply for up to 40,000 people. SF6-free solution The Fluor-gas-free blue GIS portfolio was launched by Siemens ahead of EU regulations The installation of this 24kV circuit-breaker switchgear is an important step towards a climate-friendly and smart power distribution in Davos. The Fluor-gas-free blue GIS portfolio was launched by Siemens ahead of EU regulations, serving as another proof point of the company’s focus on sustainability across its portfolio. Siemens introduced the first SF6-free solution around seven years ago, since then installed many more successfully and this being the latest addition. Net-zero targets "If we want to achieve our net-zero targets, we need to make power grids future ready with innovative, eco-friendly technology," said Matthias Rebellius, Member of the Managing Board of Siemens AG and CEO of Siemens Smart Infrastructure. Matthias Rebellius adds, "Therefore, it is essential to invest in the continued expansion of power grids. I am pleased that our long-standing customer EWD is using our pioneering switchgear technology that paves the way for climate-neutral and smart power distribution in Davos." World Economic Forum "SF6 was never ideal for the environment," said Andy Kollegger, CEO of EWD, adding "There was no doubt in our minds: If there is an alternative on the market that has the same functionality but without this disadvantage, we will switch to it." With over 1.3 million overnight guests in 2023, Davos is one of Switzerland’s biggest tourist destinations. It is also the venue for the World Economic Forum (WEF), which sees almost 3,000 guests flocking to the town each year. While close to 12,000 residents live in the highest town in the Alps year-round, Davos accommodates over 40,000 people during high season. Sustainable power distribution With over 1.3 million overnight guests in 2023, Davos is one of Switzerland’s biggest tourist destinations EWD Elektrizitätswerk Davos AG operates three substations, 168 transformer stations, 154 kilometers of medium-voltage grid and 300 kilometers of low-voltage grid in the Davos grid area. Reliable power supply is essential to a well-functioning infrastructure. At the heart of sustainable power distribution is switchgear. Its applications include substations where it connects power generators and large power consumers, such as industrial plants or data centers, to the power grid. Important role of switchgear Another important role of switchgear is monitoring and protecting power grids, for example, against short circuits. The Clean Air used as an insulating medium in the blue GIS portfolio consists of natural components of ambient air, making it climate-friendly, extremely stable, non-toxic, non-flammable, and suitable for all operating temperatures. In addition, the blue GIS switchgear is equipped with smart sensors and standardized interfaces for Electrification X. Part of Siemens Xcelerator, Electrification X is a comprehensive IoT suite that provides solutions to challenges faced by public and private power grid operators. It improves energy efficiency and enables a seamless digital and sustainable transformation.

Phytron GmbH, the globally pioneering designer and manufacturer of harsh and extreme environment motion control components and systems, will demonstrate its expertise in deep space, ultra-high vacuum and cryogenic rated motors, gear units, actuators, and drives. Accompanied on stand G16 by Mclennan, its exclusive UK distribution partner, the German specialist can count over 500 motors successfully deployed on exploration craft and satellite systems in its more than 30 years working in deep space applications. Phytron’s latest successes Phytron’s latest successes in deep space applications include motion axes for instruments used Phytron's phySPACE space-qualified stepper motors are engineered to withstand extreme levels of vibration, radiation, and temperature - and with ECSS conform materials fulfill the demanding requirements for use in ultra-high vacuum – providing high precision positioning while maintaining optimal power consumption, minimal thermal dissipation, and low weight. Phytron’s latest successes in deep space applications include motion axes for instruments used on the James Webb Space Telescope and NASA’s InSight Mars Lander. Completely customized solutions Engineers from Phytron and Mclennan will be on hand at the show to discuss potential applications in ground-based simulation and deep space deployment as standard or completely customized solutions. Mclennan has a long working history with Phytron GmbH, providing product and service support as a specialized motion component supplier and system integrator with the German Mittelstand-certified manufacturer’s products applied across extreme and harsh environment motion control tasks in industry, scientific research, and deep space.

Berkshire-based mechanical and electrical engineering firm, Campbell West, has secured a significant run of new projects for hospital refurbishment works, as the firm celebrates the landmark opportunity to work with its 25th NHS Hospital Trust. The new projects will see Campbell West delivering mechanical and electrical (M&E) engineering works at Chelsea and Westminster Oncology Department, Croydon University Hospital, Whittington Hospital, Wexham Park Hospital, and Stoke Mandeville Hospital establishing the firm’s position as one of the most trusted M&E contractors in this sector. £15 million revenue The recent spate of project wins is a significant boost to Campbell West’s revenue targets, as the firm reported a more than 53% revenue increase in its last financial year and is on course to meet the new revenue target of £ 15 million. Commenting on the new projects, Co-Founder of Campbell West, Steven Campbell, said "Securing the opportunity to work with our 25th NHS Hospital Trust is a proud moment for everyone at Campbell West." delivering exceptional results Steven Campbell adds, "It gives us an exceptional start as we look ahead to the next 12 months and puts us firmly in the position as a supplier of mechanical and electrical engineering works in the healthcare sector." He continues, "Every new contract is an opportunity for us to demonstrate our expertise and our commitment to delivering exceptional results for our clients and ultimately improving facilities for patients and healthcare staff. We are excited about building on this momentum over the coming year." Campbell West Campbell West was originally founded in 2017 by Steven Campbell and Daniel West, who met while working together as apprentices. After an exceptional period of business growth, the firm employs 30 people and is supported by a wider network of specialist contractors. With an initial focus on the healthcare sector, the company has expanded its reach to other industries including local government, education settings, data centers, workspaces, and industrial buildings, plus large residential projects.

Emerson recently partnered with Laramie Energy to help the Colorado-based oil and gas producer comply with state and federal emissions regulations. Using ASCO™ zero-emissions electric dump valves, the only such all-electric solution for separators, scrubbers, and compression units, Emerson helped Laramie Energy achieve compliance by eliminating both vented and fugitive emissions from the liquid dump stage of their separation process. emissions regulations Conventional dump valves are often piloted by well gas, which can leak into the atmosphere as vented and fugitive emissions. Some states, including Colorado, have emissions regulations that include fines for non-compliance, and the Environmental Protection Agency (EPA) has established a waste emissions charge for methane emissions that exceed specified thresholds. Detection of fugitive emissions Companies that fall out of regulation must pay expensive fines and waste subsequent downtime If fugitive emissions are detected, the EPA requires oil and gas producers to report their greenhouse gas data and conduct tests, surveys, and repairs. Companies that fall out of regulation must pay expensive fines and waste subsequent downtime to reestablish compliance. ASCO zero-emission electric dump valves In comparison, ASCO zero-emission electric dump valves use ultra-low-power electric actuation, which removes the need to vent well gas in upstream applications. And, unlike traditional dump valves, they are fugitive-emissions-free by design because they have no valve packing. Increased production, reduced power usage ASCO electric dump valves actuate in 50 to 75 milliseconds, when compared to conventional valves With precise control, ASCO electric dump valves actuate in 50 to 75 milliseconds compared to conventional valves that take several seconds, thus virtually eliminating any chance of gas blowby. This helped Laramie Energy better maintain the static pressure of their vessels, which ultimately led to an increase in natural gas production. The valves also use 1.2 watts (W) of energy, when compared to a conventional electric retrofit kit that uses 96 W, reducing valve power usage by 98.75%. cost-effective, maintenance-free alternative “Though initially designed for legacy well sites, these fully electric dump valves can help oil and gas companies achieve compliance and avoid red tape on both newly drilled production sites and existing production sites to meet new standards,” said Michael Land, Sales Development Manager with Emerson’s discrete automation business. He adds, “Our solution provides a cost-effective, maintenance-free alternative to meet compliance, when compared to other solutions like instrument air, nitrogen, and electric retrofit kits.” additional benefits Laramie Energy focuses on developing unconventional oil and gas reserves within the Rocky Mountains, operating roughly 1,500 wells. The company installed ASCO electric dump valves in newly drilled wells, while updating its legacy wells with the solution. Beyond ensuring compliance, the valves have provided additional benefits, including less maintenance and greater well efficiency.

In the overhead crane market, precision and reliability are critical due to the demanding nature of heavy-duty applications. Overhead cranes require advanced motor control systems to ensure smooth, efficient, and safe operations, particularly in lifting and transporting heavy loads. The complexity of these operations demands high-performance drives that can manage constant torque, minimize load oscillations, and provide reliable braking sequences. Delta's innovative AC motor drive solutions Addressing these unique requirements, Delta's innovative AC motor drive solutions have been successfully adapted to enhance the performance and reliability of overhead crane solutions provided by Elektro-Mak Crane Systems Ltd., a manufacturer of overhead cranes in Turkey. This collaboration has showcased Delta's strong market position and demonstrated its commitment to enhancing operational efficiency in the crane industry. Enhancing operational efficiency Elektro-Mak Crane Systems Ltd. is renowned for its expertise in producing overhead cranes Established in 1989 in Izmir, Turkey, Elektro-Mak Crane Systems Ltd. is renowned for its expertise in producing overhead cranes with capacities ranging from 250 kg to 200 tons and bridge openings below 45 meters. Operating from a state-of-the-art plant in Manisa covering 6,000 m², Elektro-Mak is a prominent player in the Turkish crane market. The company's dedication to quality and innovation has positioned it as a trusted partner for heavy-duty crane solutions. Delta and Elektro-Mak partnership The collaboration between Delta and Elektro-Mak began with the goal of enhancing the performance of overhead cranes using Delta's advanced AC motor drives. Elektro-Mak adopted Delta's C2000+ AC Motor Drives for hoisting, ME300 AC Motor Drives for long travel, and trolley operations. These drives were selected for their high-level motor control performance, competitive pricing, and robust technical support. Overcoming tough environmental conditions Delta's AC motor drives were integrated into Elektro-Mak's overhead cranes, addressing the company's need for a cost-competitive solution with an anti-sway function using open-loop control. The entire testing and commissioning process, completed in just two days, required extensive support from Delta's R&D and product management teams, particularly for parameter adjustments and overcoming tough environmental conditions. The integration process faced challenges, particularly with the anti-sway function without an encoder. However, through persistent testing and parameterization on-site, Delta's team successfully implemented a solution that met Elektro-Mak's stringent requirements. Enhancing safety and operational efficiency The success story of Elektro-Mak underscores the importance of close collaboration The results of this collaboration were outstanding. Elektro-Mak experienced a significant improvement in crane performance, with the anti-sway function and reliable braking sequence enhancing safety and operational efficiency. The ease of integration and robust performance of Delta's AC motor drives allowed Elektro-Mak to meet its production goals effectively in less time. This project is a testament to Delta's commitment to providing innovative, cost-effective automation solutions tailored to meet specific customer needs. The success story of Elektro-Mak underscores the importance of close collaboration and a thorough understanding of customer requirements. Adopting cutting-edge technologies In the words of Martien Heesterbeek, Product Manager at Industrial Automation Business Group, Delta EMEA, "This project with Elektro-Mak not only showcases our capabilities in delivering advanced automation solutions but also reinforces our commitment to customer satisfaction and innovation. We are proud to have supported Elektro-Mak in achieving significant improvements in their production processes." Şükrü Terzi, General Manager at Elektro-Mak shared his thoughts on the collaboration: "Partnering with Delta has been a transformative experience for us. The integration of their AC motor drives into our crane systems has not only boosted our production reliability and efficiency but also underscored our commitment to adopting cutting-edge technologies. Delta’s support throughout the project has been excellent, and we look forward to continuing this successful partnership." Advanced motor control systems Elektro-Mak has set a new benchmark in the overhead crane industry The collaboration between Delta and Elektro-Mak has set a new benchmark in the overhead crane industry, demonstrating the immense potential of integrating advanced motor control systems in industrial applications. As Delta continues to innovate and expand its product offerings, the company remains committed to providing reliable and efficient solutions, including both small and high-power AC drive that meet the evolving needs of the market. Leveraging Delta’s cutting-edge automation solutions Delta's unwavering dedication to problem-solving and customer support, combined with Elektro-Mak’s operational excellence and strategic insights, has forged a formidable partnership. This collaboration stands as a beacon of success in the automation industry, providing a model for others seeking superior solutions in overhead crane manufacturing. By leveraging Delta’s cutting-edge automation solutions, Elektro-Mak has set a new benchmark in the overhead crane industry, demonstrating the immense potential of integrating advanced motor control systems in industrial applications.

The Midcontinent Independent System Operator (MISO) has selected Ameren to build multiple critical energy infrastructure projects that will carry clean, reliable energy to distribution grids in Missouri, Illinois and several Midwest states. The projects, which MISO estimates will represent a total investment of approximately $1.3 billion, are part of a portfolio of energy infrastructure investments under MISO's Long-Range Transmission Plan. Strengthening the transmission system “As demand for reliable energy increases, it is imperative that we strengthen the transmission system to utilize diverse energy resources across the Midwest to support the needs of our residents and businesses,” said Shawn Schukar, Chairman and President of Ameren Transmission Company of Illinois, a subsidiary of Ameren Corporation (AEE). He adds, “The energy delivered by these projects will boost reliability and enable the bi-state region to compete for economic development opportunities, including the expansion and relocation of energy-intensive industries.” Ameren can get transmission systems energized faster Shawn Schukar continues, “Ameren can get these transmission systems energized faster and for less cost than other companies. We appreciate MISO's confidence in our team to take on these important projects.” Increasing access to diverse energy resources across the MISO footprint will ensure customer affordability The energy corridors identified in MISO’s Tranche 2.1 portfolio will work in conjunction with Ameren's current transmission system to enhance reliability and resiliency for customers, while supporting economic development. Increasing access to diverse energy resources across the MISO footprint will ensure customer affordability and access to clean energy for millions of people. Ameren to bid on Tranche 2.1 infrastructure projects Ameren plans to bid on other infrastructure projects in Tranche 2.1, where the company’s capabilities and current resources would enhance reliability, resiliency and affordability for customers. “While Ameren participated in the competitive bidding process for Tranche 1 and plans to do so again, we believe in establishing energy policy that allows the trusted local provider to develop these projects, reducing unnecessary costs and delivering value to the customers sooner,” said Shawn Schukar. He adds, “When we lead these critical projects, we finish them faster and maximize economic development.”

Siemens has installed and commissioned the world’s first 8DAB 24, the ground-breaking blue GIS medium-voltage system, in the Alpine town of Davos, Switzerland for its customer - EWD Elektrizitätswerk Davos AG. The switchgear system, which uses Clean Air as insulating gas instead of sulfur hexafluoride (SF6), is deployed in the Dorf substation in Davos, securing reliable power supply for up to 40,000 people. SF6-free solution The Fluor-gas-free blue GIS portfolio was launched by Siemens ahead of EU regulations The installation of this 24kV circuit-breaker switchgear is an important step towards a climate-friendly and smart power distribution in Davos. The Fluor-gas-free blue GIS portfolio was launched by Siemens ahead of EU regulations, serving as another proof point of the company’s focus on sustainability across its portfolio. Siemens introduced the first SF6-free solution around seven years ago, since then installed many more successfully and this being the latest addition. Net-zero targets "If we want to achieve our net-zero targets, we need to make power grids future ready with innovative, eco-friendly technology," said Matthias Rebellius, Member of the Managing Board of Siemens AG and CEO of Siemens Smart Infrastructure. Matthias Rebellius adds, "Therefore, it is essential to invest in the continued expansion of power grids. I am pleased that our long-standing customer EWD is using our pioneering switchgear technology that paves the way for climate-neutral and smart power distribution in Davos." World Economic Forum "SF6 was never ideal for the environment," said Andy Kollegger, CEO of EWD, adding "There was no doubt in our minds: If there is an alternative on the market that has the same functionality but without this disadvantage, we will switch to it." With over 1.3 million overnight guests in 2023, Davos is one of Switzerland’s biggest tourist destinations. It is also the venue for the World Economic Forum (WEF), which sees almost 3,000 guests flocking to the town each year. While close to 12,000 residents live in the highest town in the Alps year-round, Davos accommodates over 40,000 people during high season. Sustainable power distribution With over 1.3 million overnight guests in 2023, Davos is one of Switzerland’s biggest tourist destinations EWD Elektrizitätswerk Davos AG operates three substations, 168 transformer stations, 154 kilometers of medium-voltage grid and 300 kilometers of low-voltage grid in the Davos grid area. Reliable power supply is essential to a well-functioning infrastructure. At the heart of sustainable power distribution is switchgear. Its applications include substations where it connects power generators and large power consumers, such as industrial plants or data centers, to the power grid. Important role of switchgear Another important role of switchgear is monitoring and protecting power grids, for example, against short circuits. The Clean Air used as an insulating medium in the blue GIS portfolio consists of natural components of ambient air, making it climate-friendly, extremely stable, non-toxic, non-flammable, and suitable for all operating temperatures. In addition, the blue GIS switchgear is equipped with smart sensors and standardized interfaces for Electrification X. Part of Siemens Xcelerator, Electrification X is a comprehensive IoT suite that provides solutions to challenges faced by public and private power grid operators. It improves energy efficiency and enables a seamless digital and sustainable transformation.

Phytron GmbH, the globally pioneering designer and manufacturer of harsh and extreme environment motion control components and systems, will demonstrate its expertise in deep space, ultra-high vacuum and cryogenic rated motors, gear units, actuators, and drives. Accompanied on stand G16 by Mclennan, its exclusive UK distribution partner, the German specialist can count over 500 motors successfully deployed on exploration craft and satellite systems in its more than 30 years working in deep space applications. Phytron’s latest successes Phytron’s latest successes in deep space applications include motion axes for instruments used Phytron's phySPACE space-qualified stepper motors are engineered to withstand extreme levels of vibration, radiation, and temperature - and with ECSS conform materials fulfill the demanding requirements for use in ultra-high vacuum – providing high precision positioning while maintaining optimal power consumption, minimal thermal dissipation, and low weight. Phytron’s latest successes in deep space applications include motion axes for instruments used on the James Webb Space Telescope and NASA’s InSight Mars Lander. Completely customized solutions Engineers from Phytron and Mclennan will be on hand at the show to discuss potential applications in ground-based simulation and deep space deployment as standard or completely customized solutions. Mclennan has a long working history with Phytron GmbH, providing product and service support as a specialized motion component supplier and system integrator with the German Mittelstand-certified manufacturer’s products applied across extreme and harsh environment motion control tasks in industry, scientific research, and deep space.

Berkshire-based mechanical and electrical engineering firm, Campbell West, has secured a significant run of new projects for hospital refurbishment works, as the firm celebrates the landmark opportunity to work with its 25th NHS Hospital Trust. The new projects will see Campbell West delivering mechanical and electrical (M&E) engineering works at Chelsea and Westminster Oncology Department, Croydon University Hospital, Whittington Hospital, Wexham Park Hospital, and Stoke Mandeville Hospital establishing the firm’s position as one of the most trusted M&E contractors in this sector. £15 million revenue The recent spate of project wins is a significant boost to Campbell West’s revenue targets, as the firm reported a more than 53% revenue increase in its last financial year and is on course to meet the new revenue target of £ 15 million. Commenting on the new projects, Co-Founder of Campbell West, Steven Campbell, said "Securing the opportunity to work with our 25th NHS Hospital Trust is a proud moment for everyone at Campbell West." delivering exceptional results Steven Campbell adds, "It gives us an exceptional start as we look ahead to the next 12 months and puts us firmly in the position as a supplier of mechanical and electrical engineering works in the healthcare sector." He continues, "Every new contract is an opportunity for us to demonstrate our expertise and our commitment to delivering exceptional results for our clients and ultimately improving facilities for patients and healthcare staff. We are excited about building on this momentum over the coming year." Campbell West Campbell West was originally founded in 2017 by Steven Campbell and Daniel West, who met while working together as apprentices. After an exceptional period of business growth, the firm employs 30 people and is supported by a wider network of specialist contractors. With an initial focus on the healthcare sector, the company has expanded its reach to other industries including local government, education settings, data centers, workspaces, and industrial buildings, plus large residential projects.

Emerson recently partnered with Laramie Energy to help the Colorado-based oil and gas producer comply with state and federal emissions regulations. Using ASCO™ zero-emissions electric dump valves, the only such all-electric solution for separators, scrubbers, and compression units, Emerson helped Laramie Energy achieve compliance by eliminating both vented and fugitive emissions from the liquid dump stage of their separation process. emissions regulations Conventional dump valves are often piloted by well gas, which can leak into the atmosphere as vented and fugitive emissions. Some states, including Colorado, have emissions regulations that include fines for non-compliance, and the Environmental Protection Agency (EPA) has established a waste emissions charge for methane emissions that exceed specified thresholds. Detection of fugitive emissions Companies that fall out of regulation must pay expensive fines and waste subsequent downtime If fugitive emissions are detected, the EPA requires oil and gas producers to report their greenhouse gas data and conduct tests, surveys, and repairs. Companies that fall out of regulation must pay expensive fines and waste subsequent downtime to reestablish compliance. ASCO zero-emission electric dump valves In comparison, ASCO zero-emission electric dump valves use ultra-low-power electric actuation, which removes the need to vent well gas in upstream applications. And, unlike traditional dump valves, they are fugitive-emissions-free by design because they have no valve packing. Increased production, reduced power usage ASCO electric dump valves actuate in 50 to 75 milliseconds, when compared to conventional valves With precise control, ASCO electric dump valves actuate in 50 to 75 milliseconds compared to conventional valves that take several seconds, thus virtually eliminating any chance of gas blowby. This helped Laramie Energy better maintain the static pressure of their vessels, which ultimately led to an increase in natural gas production. The valves also use 1.2 watts (W) of energy, when compared to a conventional electric retrofit kit that uses 96 W, reducing valve power usage by 98.75%. cost-effective, maintenance-free alternative “Though initially designed for legacy well sites, these fully electric dump valves can help oil and gas companies achieve compliance and avoid red tape on both newly drilled production sites and existing production sites to meet new standards,” said Michael Land, Sales Development Manager with Emerson’s discrete automation business. He adds, “Our solution provides a cost-effective, maintenance-free alternative to meet compliance, when compared to other solutions like instrument air, nitrogen, and electric retrofit kits.” additional benefits Laramie Energy focuses on developing unconventional oil and gas reserves within the Rocky Mountains, operating roughly 1,500 wells. The company installed ASCO electric dump valves in newly drilled wells, while updating its legacy wells with the solution. Beyond ensuring compliance, the valves have provided additional benefits, including less maintenance and greater well efficiency.

Power Beat

Electricians play a pivotal role in preventing electrical fires by following safe practices during installations, repairs, and inspections. At a minimum, electricians should ensure all electrical wiring and components are installed according to current building codes and manufacturers' specifications. This includes using the right size wires for the amperage load, using approved materials, and properly securing all connections. During electrical inspections, electricians should identify and address any potential fire hazards. Electricians can also advise homeowners on electrical safety measures they can take to prevent fires. These include safe appliance use, avoiding overloaded outlets, and the importance of smoke detectors and fire extinguishers. Maintenance of electrical systems Ground Fault Circuit Interrupters (GFCIs) can prevent possible fires. GFCI outlets have built-in protection to detect imbalances in electrical current and quickly shut off power to prevent shocks and potential fires, particularly in areas prone to moisture like kitchens and bathrooms. Regular maintenance of electrical systems is also crucial for fire prevention. Electricians can perform preventative maintenance checks to identify and address any developing issues before they become serious fire hazards. Fire departments responded to an average of 32,160 home fires involving electrical distribution Fire departments responded to an average of 32,160 home fires involving electrical distribution and lighting equipment each year in 2015–2019, according to the National Fire Protection Association (NFPA). Electrical fires cause scores of civilian deaths and hundreds of civilian injuries, as well as millions of dollars in property damage. Fire Hazards in the Home Some of the electrical components that present fire hazards in the home include faulty electrical outlets and switches, worn or damaged components, overloaded circuits, damaged or frayed cords, and misused extension cords and power strips. Improper use of light fixtures can also be a danger, and space heaters can be a fire hazard if they are placed too close to flammable materials or left unattended. Damaged or frayed cords can cause sparks and ignite nearby flammable materials As outlets and switches age, the wiring behind them can loosen and break, causing sparks and fire. Loose plugs can also overheat and ignite surrounding materials. Plugging too many appliances into a single outlet or using extension cords instead of proper wiring can overload a circuit, thus causing overheating and fires. Damaged or frayed cords can cause sparks and ignite nearby flammable materials. Cords that are kinked, pinched, or have exposed wires should be avoided and replaced immediately. Minimizing the Risk of Electrical Fires Here are some steps a homeowner can take to minimize the risk of fire from electrical systems: Upgrade the electrical system, especially if the home is older. If the electrical system has not been updated in a while, a qualified electrician can advise if it needs modernization. This could involve upgrading to breakers with better safety features such as Arc-Fault Circuit Interrupter (AFCI) and Ground Fault Circuit Interrupter (GFCI) technology. Schedule an electrical safety inspection. Having a qualified electrician periodically inspect a home's electrical system can identify potential problems before they escalate into fire hazards. Keep flammable materials away from electrical components, including curtains, furniture, and piles of paper. Sparks and overheating can easily ignite nearby flammables. Addressing Multiple Threats Effective communication is key for electricians to impress upon homeowners the seriousness of fire hazards. Avoid technical jargon and explain fire hazards in clear, concise language that homeowners can understand. Focus on the potential consequences, like damage to property or injury, to heighten awareness. Pictures can be worth a thousand words. Show homeowners examples of damaged wiring, overloaded outlets, or faulty installations that pose fire risks. This can be done through photos on a tablet or phone, or even carrying around small physical samples. Frame the conversation around safety for the homeowner and their family. Highlight how addressing these hazards can prevent potential fires and ensure a safe living environment. Provide a written report after the inspection or repair. This report should detail the identified hazards, the corrective actions taken, and any recommendations for future maintenance or upgrades. By combining clear communication, visual aids, and a focus on safety, electricians can effectively convey the importance of addressing fire hazards to homeowners and empower them to make informed decisions about their electrical systems.

Rising material prices and inflation, in general, are likely to continue to plague electricians and others in the trade service businesses, according to a new survey conducted by the business management software platform Simpro. In the survey, 20% of electrical respondents say they are more likely to face rising material prices this year, while 20% of owners, CEOs, and business managers in the broader category of trade service businesses are more likely to face inflation concerns. ongoing economic uncertainty Another big concern across all trade service businesses is staff retention. Even higher percentages of survey respondents expect continuing challenges presented by the labor market: 73% anticipate hiring to be more challenging in 2023 than last year because of a lack of skilled workers (cited by 51% of respondents) and ongoing economic uncertainty (cited by 50%). The survey, conducted in January 2023, also highlighted changes trade service companies saw in the market last year compared to 2021. Customer acquisition Customer acquisition was more challenging in 2022, according to 66% of survey respondents In a service-based industry, customer satisfaction is a high priority: 95% of trade professionals noted that customer experience is paramount, and 73% have adopted technology tools specifically designed to enhance the customer experience. Customer acquisition was more challenging in 2022, according to 66% of survey respondents, while customer retention was more challenging for 60% of respondents. Hiring was also more difficult than in 2021, according to 76% of the survey respondents. Simpro’s smart technology solutions In the survey, Simpro seeks to highlight the ways technological innovations can shape the future of trade services businesses and their customers. Simpro’s total business management software platform for commercial trade service businesses performs functions such as job quoting, scheduling, inventory tracking, invoicing, and others. Simpro’s smart technology solutions and expert long-term support help businesses build, repair and power their future with control over operations. “Voice of the Trades” survey Trade professionals are estimated to spend more than 18 hours a week on tasks such as scheduling In the “Voice of the Trades” survey, 72% of trade professionals (including HVAC, security, plumbers, contractors, electricians, and others) believe that new software and technology must be adopted to remain competitive. Also, 60% feel that administrative burdens have a negative impact on their ability to service customers. Trade professionals, including electricians, estimate they spend more than 18 hours a week on tasks such as scheduling, inventory, invoicing and overall workflow management. The report reveals why it is so hard to find a contractor or service technician right now: 49% of respondents share a belief that time on admin has directly contributed to that customer frustration. Clear roadmap for operational efficiency “The Voice of the Trades findings confirm the need for trade businesses worldwide to implement technology solutions to lessen the burden of business management in any economy,” said Gary Specter, CEO of Simpro. “This research provides a clear roadmap for improving operational efficiency so trade organizations can better serve their customers.” The report gleaned feedback from 840 respondents who are trade industry professionals, with a geographic pool that includes the U.S., U.K., Australia, New Zealand, and Canada. Founded in 2002 by an electrical contractor and headquartered in Brisbane, Australia, Simpro supports more than 8,000 businesses and 200,000 users worldwide in the electrical, plumbing, HVAC, security and fire protection industries with 700-plus employees in six offices around the world.

Case studies

Zermatt is a truly unique destination nestled in the Swiss Alps. The town is primarily renowned for its iconic Matterhorn Mountain, which stands at 4,478 meters and is one of the highest and most recognizable peaks in the Alps. Zermatt’s landscape includes 38 peaks over 4,000 meters. With around 2.5 million overnight stays recorded in 2023, Zermatt is one of the most popular tourist destinations in Switzerland. However, due to the town’s remote location and rugged terrain, Zermatt faces specific challenges. These include the need for reliable and sustainable infrastructure and the management of natural risks, such as avalanches and extreme weather events, which can disrupt infrastructure and pose safety concerns. These factors, combined with the altitude difference, oxygen-deficient air, and steep terrain, underscore the need for innovative solutions. For decades, together with its innovative customers, Siemens has been developing technological solutions to meet these challenges. Evaluation of energy flows The hut operates mainly autonomously and is largely self-sufficient in its energy needs The Monte Rosa Hut, located 2,883 meters above sea level, is one of the most iconic mountain huts in Switzerland. The high-tech hut has been equipped with Siemens building technology since its reopening in 2010. In 2021, 8.6 tons of lead batteries were replaced by 2.7 tons of lithium batteries. Continuous online evaluation of energy flows indicated the need for a new solution as the existing lead batteries would soon reach the end of their lifespan. The hut operates mainly autonomously and is largely self-sufficient in its energy needs. With the building management system Desigo CC, as the comprehensive on-site solution to manage all the systems, such as HVAC, Shading, Lighting, Power, Fire Safety, and Security, the operator can quickly review the key equipment values, check key room KPIs, and troubleshoot any potential problems. Troubleshooting potential problems In 2024, the open and flexible IoT platform “Building X” from Siemens was deployed. Building X is the scalable digital building platform to digitalize, manage, and optimize building operations, allowing for an enhanced user experience, increased performance, and improved sustainability. The Matterhorn summer paradise offers bike trails, adventurous kickbike and dirt scooter descents Zermatt Bergbahnen AG is Switzerland’s largest cable car company. The cable car station ‘Matterhorn glacier paradise’ is Europe’s highest cable car station at 3,883 m above sea level. It offers year-round snow experiences and stunning views of 38 peaks over 4,000 m. The Matterhorn summer paradise offers bike trails, adventurous kickbike and dirt scooter descents, and 400 km hiking trails. In the winter, the company offers, together with Cervinia/Valtournenche, 54 lifts and a total of 360 km of slopes. Rapidly changing weather Infrastructure in mountainous and challenging terrain demands high standards due to factors such as altitude, low oxygen levels, and rapidly changing weather. Siemens and Zermatt Bergbahnen share a long-standing and successful partnership in areas such as low-voltage power supply and state-of-the-art control solutions, which has been expanded with the completion of the Matterhorn Alpine Crossing and the connection from Matterhorn Glacier Paradise to Testa Grigia in Italy. Siemens solutions provide complete transparency and traceability of the system, thereby ensuring a seamless energy management overview of the entire infrastructure. This system ensures that all the energy values can be managed directly on the control units and displayed graphically on a state-of-the-art display/HMI or SCADA. Data from different subsystems provided by a wide range of manufacturers can be easily integrated into the overall Siemens system via standardized interfaces. Remote management of critical systems The Gornergrat Railway (GGB) and Matterhorn Gotthard Railway (MGB) are part of the BVZ Group The Gornergrat Railway (GGB) and Matterhorn Gotthard Railway (MGB) are part of the BVZ Group, which includes 10 subsidiaries. The BVZ Group provides public transport and tourism services in the cantons of Valais, Uri, and Grisons. The GGB adopted the first cloud-based operational model in 2017, which was facilitated by Siemens Mobility. It ensures seamless and reliable operation. This innovative approach eliminates the need for on-site server infrastructure and allows for the remote management of critical systems. The integrated control and information system, known as “Iltis”, enhances operational efficiency and safety. This system enables remote control of signaling, monitoring of operations, and management of passenger information systems. Streamlining depot operations Another world premiere in 2023: The first mobile depot control system in the cloud, the Controlguide® TrackOps Depot, for the Matterhorn Gotthard Bahn. Controlguide® TrackOps Depot is an innovative depot control solution, enabling the local management of shunting activities and streamlining depot operations. Utilizing cloud-based technologies, Siemens provided flexible and scalable depot control solutions to ensure the efficient management of railway operations. Tablet-based control interfaces were introduced for depot operations, thereby enabling the simplified and efficient management of shunting activities directly from the field.

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.

Jenkins sold a Jenkins Motor Test System to Oman, where temperatures can exceed 120ºF. While Jenkins Motor Test Systems are built tough and for industrial environments, this specific location required customizations to be the most effective in an extremely hot environment. Locations near large bodies of water or tropical environments can also cause problems as the humidity in the air will cause the copper wiring in the transformer to oxidize over time. Although Jenkins designs its equipment to operate for long periods, some applications for customer environments require specific customization. The Solution Jenkins engineers and winders worked together to develop a custom solution for this harsh climate, particularly paying close attention to temperature and water resistance. To customize the transformer for this environment, the Jenkins team made the following modifications: Doubling the spacing between winding layers to increase airflow. Encasing the transformer first in a high tolerance epoxy varnish, and then in a polyester over-dip that prevents the application from rust, dust, and harmful materials. Utilizing expanded metal at the base of the MTS enclosure, allows heat to escape, reducing the internal temperature. Installing temperature-sensitive cooling fans (set to 100ºF) atop the enclosure to prevent overheating. The Results Jenkins technicians checked insulation for 10,000 volts (resistance to ground), checked each voltage leg, and high voltage potential to ground, and ensured the taps were in the correct place. Voltage was confirmed to operate up to 20% above normal operation, ensuring maximum efficiency and longevity of the transformer. These modifications have resulted in prolonged use of the Jenkins Motor Test System in harsh environments and ultimately customer satisfaction.

As part of a long-term modernization project at the Baltimore Washington International (BWI) Airport, Helios Electric was retained to perform design-assist, system integration, and on-site field engineering services. The project involved replacing an existing 7.5/10.5 MVA outdoor substation transformer and performing retrofit services at the corresponding medium-voltage switchgear lineups. The project also included enhancements to the electrical system protection since power reliability was deemed vital for airport operations. SEL-787 transformer protection relay A new SEL-787 transformer protection relay was installed to perform advanced transformer monitoring, controls, and system protection. New pilot control devices were installed on the corresponding switchgear lineups to indicate transformer faults, alarms, and mechanical conditions. Vacuum circuit breakers at the existing switchgear lineups were retained and modified to establish connectivity with the new substation transformer and the new transformer protection relay. transformer protection functions This installation approach yielded improved protection for the new transformer while limiting the scope, budget, duration, and power outages required to accomplish the necessary tasks. The improved transformer protection functions included the following: ANSI-87 – Current Differential Protection ANSI-87G – Restricted Earth Fault Protection ANSI-50/51 – Phase Overcurrent Protection (Backup) ANSI-50/51G – Ground Overcurrent Protection (Backup) ANSI-63 – Transformer Sudden Pressure ANSI-71 – Transformer Low Oil Level ANSI-49 – Transformer High Winding Temperature ANSI-26 – Transformer High Oil Temperature AC/DC control modifications To fulfill the customer’s desired requirements, the Helios Electric team investigated the internal circuitry of the switchgear lineups and ascertained the specific AC/DC control modifications required at the existing. Work performed under this project included the following: Examining and analyzing the components and sub-components of the existing switchgear lineups. Tracing the existing 35kV-class and 15kV-class vacuum circuit breakers to determine the existing field configuration. Developing modified equipment shop drawings for approval, construction, and as-built conditions. Programming and configuration of SEL-787 Transformer Protection Relay to establish system protection, controls, and integration with the facility’s Supervisory Control and Data Acquisition (SCADA) System. Installing and modifying existing 35kV-class and 15kV-class vacuum circuit breaker controls to accommodate the new substation transformer and transformer protection relay. Developing Operation & Maintenance (O&M) manuals for modified electrical equipment lineups. On-site electrical equipment training for airport maintenance personnel.

SoFi Stadium, a world-class venue, turned to industry major - Belden for a complete end-to-end cabling and connectivity solution. Belden’s cutting-edge technology supports the stadium’s data-heavy demands, including the one-of-a-kind, roof-suspended Oculus video board, Wi-Fi infrastructure, digital ticketing, and a DAS system. Belden’s solutions for SoFi Stadium When the stadium’s owners required a solution that delivered top-tier quality, performance, and reliability while reducing labor costs, they called Belden. Count on Arrow to deliver unparalleled excellence in the low-voltage industry. Arrow will equip with the competitive advantage needed for any customer, any configuration, and any budget. Copper Cables & Copper Solutions Discover the ultimate lineup of Belden Inc. category cables, tailored to suit every application imaginable! Discover the ultimate lineup of Belden Inc. category cables, tailored to suit every application imaginable! Many cables featured their signature patented Bonded-Pair design, guaranteeing unparalleled signal integrity. Plus, with DataTuff® Industrial category cables, rest assured the system remains resilient against the toughest environmental conditions. Category 6A Choose from an assortment of configurations including small diameter, snake, industrial, non-bonded, and their innovative patented Bonded-Pair technology. Elevating performance benchmarks, Belden's renowned 10GXS Cable stands as the gold standard in the industry. Category 6 Belden has a wide array of Category 6 performance options, featuring their top-of-the-line REVConnect 3600 System cable boasting premium performance and ample headroom. The REVConnect 2400 System cable, surpasses TIA-568-C.2 standards, all backed by Belden’s renowned quality. Category 5e Belden presents a range of Category 5e performance options, with their flagship 1200 Series cable delivering exceptional headroom, surpassing the TIA-568-C.2 Category 5e standard. Featuring Bonded-Pair technology, their 1200 Series ensures unparalleled robustness in installations. Patch Panel Belden’s commercial-grade panels are available in modular (empty) configurations Belden offers a comprehensive range of copper patch panels tailored to meet the demands of both commercial and industrial settings. Belden’s commercial-grade panels are available in modular (empty) configurations or pre-loaded with high-quality copper jacks designed for Category 6A, 6, and 5E network installations. Trunk Cable Optimized for data centers, enterprise networks, and any environment prioritizing swift installation, Trunk Cable Assemblies offer factory termination and rigorous testing, slashing installation time by up to 90%. Eliminating the need for termination, these assemblies come in diverse lengths, equipped with connectors tailored to specific application requirements. Patch Cord Enhancing both performance and physical durability, Belden’s Copper Patch Cords ensure optimal transmission quality for network channels. With superb return loss characteristics adaptable to any environment, Belden’s Copper Patch Cords come in modular, small-diameter, and traceable solutions to meet specific needs. Fiber Cable & Fiber Solutions Discover an array of high-quality indoor and outdoor cable solutions within Belden’s comprehensive product line, featuring both tight buffer and loose tube designs. Tailored for diverse industrial settings, their offerings include armored, burial, and ruggedized options. Crafted to meet various specifications, their product range encompasses OM1, OM3, OM4, OM5, and OS2 (Single Mode) configurations. Tight Buffer Fiber Cables Tight-Buffered Fiber Cables are perfectly tailored for enterprise environments Tight-Buffered Fiber Cables are perfectly tailored for enterprise environments, these cables stand out as a crowd favorite, ideal for intra-building backbones and both horizontal and vertical installations. Offering versatility like no other, they come in fiber counts ranging from two to an impressive 144, making them adaptable to any project scale. Whether indoors or outdoors, these cables are engineered to exceed expectations, boasting a design that ensures seamless performance in any environment. Loose Tube Cables Belden’s Loose Tube Cables offer the ultimate solution for all outdoor and indoor/outdoor fiber optic needs. Whether it’s for OSP, conduit, direct burial, aerial, or trunking applications, Belden’s cables offer unmatched versatility and performance. Choose from a variety of options including dry or gel-filled single and double-jacket designs, with plenum and riser ratings. Armored Cables Belden’s armored cables are designed to withstand harsh environmental conditions, including extreme temperatures, moisture, and physical damage. The armor layer provides an extra level of protection against mechanical stresses, such as crushing, impact, and abrasion, ensuring the longevity and reliability of the cable. It also helps to maintain cable integrity in areas prone to disturbances such as rodent activity. Connectors Belden’s connectors seamlessly integrate fusion splicing with field-installable connectors Belden’s connectors seamlessly integrate the advantages of fusion splicing with the ease of field-installable connectors, they greatly enhance flexibility for field termination, while elevating installation performance and reliability beyond traditional mechanical splice connectors. Eliminating the need for crimping, polishing, or adhesives during termination significantly reduces installation errors. Cassettes Belden offers an advanced DCX and LAN Cassettes platform designed to cater to a wide spectrum of density requirements, ranging from low to ultra-high density applications. Cassettes platform encompasses frames, cassettes, and covers for a comprehensive array of connector types, including LC, SC, ST, and MPO connectors, as well as Copper RJ45 Jacks and Couplers. Patch Cords Simplified, durable, adaptable, and readily accessible. Unmatched quality and performance define Belden's FX patch cords, engineered with a robust design to endure daily wear and tear. Available in standard configurations off the shelf or swiftly customized for tailored installations, they ensure reliability in any setting.

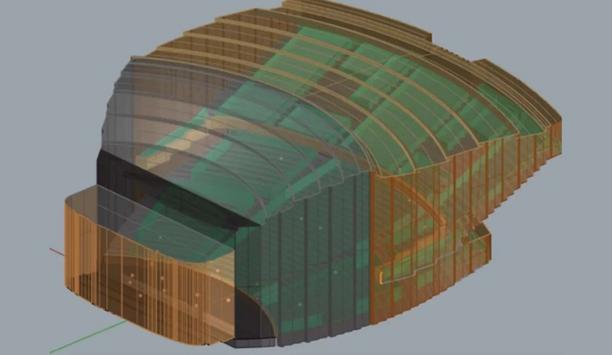

Siemens has developed a digital twin especially for large event spaces. The technology makes it possible to realistically reproduce and simulate very precisely a building’s acoustics and structure. The Sound of Science application will be used for the first time in the Großes Festspielhaus – the Large Festival Hall – at the Salzburg Festival. Sound of Science application Orchestral formations on the stage can also be tested and arranged in advance Sound of Science will enable event organizers to virtually explore how acoustics change in different spatial configurations – for example, how adding acoustic panels affects the listening experience – in order to select the optimal acoustic scenario. Orchestral formations on the stage can also be tested and arranged in advance – before a single note is heard in the real world. This approach saves money, resources and time. Siemens to use digital twins “With Sound of Science, we’re designing the future. Digital twins are not only transforming the everyday for many companies, but are also creating new opportunities for the cultural and creative industries,” said Prof. Dr. Stephan Frucht, Artistic Director of the Siemens Arts Program. Dr. Stephan Frucht adds, “In the future, we’ll be able to plan stage productions better and even simulate them acoustically in advance. We’re delighted to have the Salzburg Festival at our side as a long-standing partner, who recognizes the opportunities such innovations offer.” Sound of Science app for select partners Siemens will make the Sound of Science app available to selected partners from the cultural world free of charge as a demonstration application. There are currently no plans to market the application. Its simulation solutions, however, may be purchased. The Salzburg Festival’s Großes Festspielhaus is the first and only large event space to date in which Sound of Science is available. However, Siemens is planning to digitally simulate further spaces – including concert halls in Germany and England. At the Salzburg Festival, audiences will have an opportunity – unique for the time being – to use VR glasses to experience the application at the festival’s opening on July 20. Siemens and the Salzburg Festival “Siemens and the Salzburg Festival share a common passion for excellence and innovation. And we’re delighted to partake in this pioneering technological development and innovation as part of our long-standing close and trust-based partnership,” said Dr. Kristina Hammer, President of the Salzburg Festival. Dr. Kristina Hammer adds, “We’re excited to see what diverse applications will stem from Sound of Science in the future.” Siemens Simcenter’s simulation solutions The technologies used are part of the simulation solutions from Siemens Simcenter The technologies used are part of the simulation solutions from Siemens Simcenter, which has been part of the company’s core business for over 15 years. The technology is mostly used in industry – for example, for the acoustic optimization of vehicle interiors or for protection against street noise. For Sound of Science, Simcenter uses a combination of impulse response measurements and ray tracing for the 3D modeling of each event space. These methods can measure the echo and reverberation of a sound and simulate how sound waves propagate in a room. Depending on the material, reflections of sound waves behave differently. Those that bounce off a concrete wall react differently from those that hit a carpet or reach the ear directly. As a result, the simulation can reproduce the individual sound signature of each event space – in other words, its acoustic DNA. Siemens Festival Nights Siemens has been working closely with the Salzburg Festival for around 30 years. Since 1999, the company has also been the festival’s main sponsor. Since 2002, the Siemens Festival Nights have been held on Kapitelplatz square during the Salzburg Festival. Since its beginning, this open-air event has provided more than one million visitors with the opportunity to experience previous and current festival productions on an LED screen free of charge. In addition, some of the Salzburg Festival’s venues are equipped with Siemens technology from the areas of building automation, security and acoustics.

Zermatt is a truly unique destination nestled in the Swiss Alps. The town is primarily renowned for its iconic Matterhorn Mountain, which stands at 4,478 meters and is one of the highest and most recognizable peaks in the Alps. Zermatt’s landscape includes 38 peaks over 4,000 meters. With around 2.5 million overnight stays recorded in 2023, Zermatt is one of the most popular tourist destinations in Switzerland. However, due to the town’s remote location and rugged terrain, Zermatt faces specific challenges. These include the need for reliable and sustainable infrastructure and the management of natural risks, such as avalanches and extreme weather events, which can disrupt infrastructure and pose safety concerns. These factors, combined with the altitude difference, oxygen-deficient air, and steep terrain, underscore the need for innovative solutions. For decades, together with its innovative customers, Siemens has been developing technological solutions to meet these challenges. Evaluation of energy flows The hut operates mainly autonomously and is largely self-sufficient in its energy needs The Monte Rosa Hut, located 2,883 meters above sea level, is one of the most iconic mountain huts in Switzerland. The high-tech hut has been equipped with Siemens building technology since its reopening in 2010. In 2021, 8.6 tons of lead batteries were replaced by 2.7 tons of lithium batteries. Continuous online evaluation of energy flows indicated the need for a new solution as the existing lead batteries would soon reach the end of their lifespan. The hut operates mainly autonomously and is largely self-sufficient in its energy needs. With the building management system Desigo CC, as the comprehensive on-site solution to manage all the systems, such as HVAC, Shading, Lighting, Power, Fire Safety, and Security, the operator can quickly review the key equipment values, check key room KPIs, and troubleshoot any potential problems. Troubleshooting potential problems In 2024, the open and flexible IoT platform “Building X” from Siemens was deployed. Building X is the scalable digital building platform to digitalize, manage, and optimize building operations, allowing for an enhanced user experience, increased performance, and improved sustainability. The Matterhorn summer paradise offers bike trails, adventurous kickbike and dirt scooter descents Zermatt Bergbahnen AG is Switzerland’s largest cable car company. The cable car station ‘Matterhorn glacier paradise’ is Europe’s highest cable car station at 3,883 m above sea level. It offers year-round snow experiences and stunning views of 38 peaks over 4,000 m. The Matterhorn summer paradise offers bike trails, adventurous kickbike and dirt scooter descents, and 400 km hiking trails. In the winter, the company offers, together with Cervinia/Valtournenche, 54 lifts and a total of 360 km of slopes. Rapidly changing weather Infrastructure in mountainous and challenging terrain demands high standards due to factors such as altitude, low oxygen levels, and rapidly changing weather. Siemens and Zermatt Bergbahnen share a long-standing and successful partnership in areas such as low-voltage power supply and state-of-the-art control solutions, which has been expanded with the completion of the Matterhorn Alpine Crossing and the connection from Matterhorn Glacier Paradise to Testa Grigia in Italy. Siemens solutions provide complete transparency and traceability of the system, thereby ensuring a seamless energy management overview of the entire infrastructure. This system ensures that all the energy values can be managed directly on the control units and displayed graphically on a state-of-the-art display/HMI or SCADA. Data from different subsystems provided by a wide range of manufacturers can be easily integrated into the overall Siemens system via standardized interfaces. Remote management of critical systems The Gornergrat Railway (GGB) and Matterhorn Gotthard Railway (MGB) are part of the BVZ Group The Gornergrat Railway (GGB) and Matterhorn Gotthard Railway (MGB) are part of the BVZ Group, which includes 10 subsidiaries. The BVZ Group provides public transport and tourism services in the cantons of Valais, Uri, and Grisons. The GGB adopted the first cloud-based operational model in 2017, which was facilitated by Siemens Mobility. It ensures seamless and reliable operation. This innovative approach eliminates the need for on-site server infrastructure and allows for the remote management of critical systems. The integrated control and information system, known as “Iltis”, enhances operational efficiency and safety. This system enables remote control of signaling, monitoring of operations, and management of passenger information systems. Streamlining depot operations Another world premiere in 2023: The first mobile depot control system in the cloud, the Controlguide® TrackOps Depot, for the Matterhorn Gotthard Bahn. Controlguide® TrackOps Depot is an innovative depot control solution, enabling the local management of shunting activities and streamlining depot operations. Utilizing cloud-based technologies, Siemens provided flexible and scalable depot control solutions to ensure the efficient management of railway operations. Tablet-based control interfaces were introduced for depot operations, thereby enabling the simplified and efficient management of shunting activities directly from the field.

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.