Grid Parity

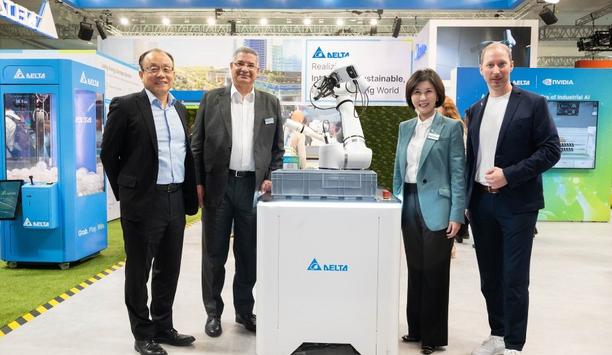

Delta, a global pioneer in power management and smart green solutions, highlighted at Hannover Messe 2025 a versatile set of AI-driven smart manufacturing, energy infrastructure, and data centre solutions. These include, the award-winning D-Bot series cobots, featuring advanced cognitive capabilities and integration with NVIDIA Omniverse to develop next-generation digital twins; and DeltaGrid®, the AI-enabled energy management platform to optimize efficiency in the energy infrastructure sup...

On June 7, 2021, the generator terminal subsynchronous damping control (GTSDC) system of Datang Xilinhaote (Xilinhot) power plant completed the oscillation suppression test and put into operation successfully. NR worked as the total solution provider for this project. The successful operation of the system enhances the damping performance of the complex resonance between the generator and the grid, and can effectively solve the torsional vibration problem of the turbine generator shaft system u...

On June 3, the Huzhou distributed power flow controller (DPFC) pilot project, developed and supplied by NR, successfully withstood the manual short circuit test. The system responded accurately and the test results met the expectations. The success of this manual short-circuit test fully verified the ability of NR DPFC ability to withstand AC short-circuit current, AC fault ride through ability, and the accuracy of cooperation with AC line protection, marking that the 220 kV DPFC project has al...

On January 20, 2022, the first converter valve of the China Great Bay Area DC back-to-back project was successfully put into operation for the first time, marking an important step forward for the interconnection of the core areas of the Eastern and Western Pearl River Delta of the Guangdong power grid. The converter valves were supplied by NR. Unit 1 on the East side of Guangzhou took the lead in entering the system commissioning stage among the four units of the whole project, creating a new...

Luxi Island microgrid system, which was designed, supplied, commissioned and delivered by NR, has been successfully put into operation. The system effectively solved the black start problem of 10kV feeder level microgrid with impulsive load, and has won high recognition from users with an advanced and intelligent control strategy, a stable and reliable microgrid system. Power supply of Luxi Island The power supply of Luxi Island was transmitted remotely by submarine cables Luxi Island is loc...

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, unveiled its broad spectrum of next-generation power and liquid cooling solutions at NVIDIA GTC 2025. These solutions are designed to bolster the performance and energy conservation in NVIDIA-enabled AI and HPC data centers, including the newly launched Power Capacitance Shelves and in-row 1.5MW liquid-to-liquid Coolant Distribution Units (CDU). NVIDIA Omniverse™ platform Delta’s AI-based Smart...

News

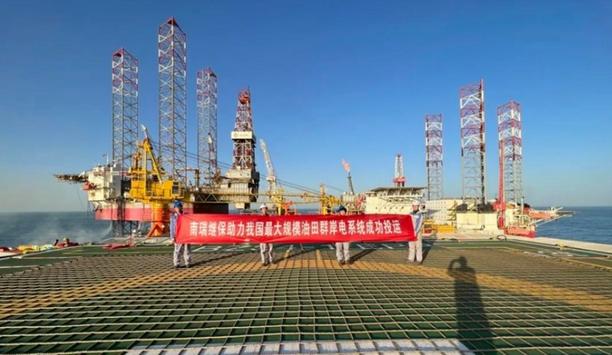

Recently China’s largest offshore oilfield group using land grid power supply application project - CNOOC Bozhong-Kenli Oilfield Group Shore Power Application Demonstration Project in the Bohai Sea region was successfully put into operation. Bozhong Kenli Oilfield shore power project includes onshore 220kV Haiguo switching station, offshore 220kV Haitai electric power platform, 220kV Haimin electric power platform, 220kV Hai'an electric power platform and 110kV Haixiang electric power platform. With the successful power transmission of each substation, it marks that the offshore and onshore backbone parts of Bozhong Kenli shore power project of Bohai Oilfield have been completed as scheduled. High energy consumption Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development as fuel for power generation, which not only has low efficiency and high energy consumption, and the stability is far lower than that of the large power grid. Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development After the shore power project is put into operation, compared with the peak year of power generation, the natural gas consumption will be reduced by 1.5 billion m3, the annual energy saving will be nearly 650,000 tons and other standard coals, which is equivalent to reducing carbon dioxide emissions by 1 million tons. Secondary system equipment The successful operation of the project will further change the previous "self-generation mode" of China's offshore oil fields. It is of great strategic significance for China to promote the adjustment of the national energy structure, achieve the goal of energy conservation and emission reduction, promote the green development of offshore oil and gas fields. As the supplier of the overall secondary system equipment of the shore power project, NR has provided a full set of core equipment such as integrated automation system, dispatching system, centralized control center, protection equipment, safety and stability control system, excitation inrush current suppressor, etc. for the four 220kV substations and one 110kV substation of the project. Special offshore environment NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology At the beginning of the project, NR went deep into the unique characteristics of the power grid structure and operation & maintenance of the Bozhong Kenli shore power project, and carried out in-depth relevant system research, simulation calculation and scheme design with CNOOC. As all systems of the offshore electric power platform are in the special offshore environment of high humidity and salinity, all complete sets of equipment provided by NR have passed the acceptance of the classification society of the classification society company, fully meeting the long-term, high requirements and high standards of operation in the offshore environment. NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology, excellent products and professional services, providing strong support for the power network construction of the world's largest offshore oilfield group. Ensuring energy security The smooth operation of Bozhong Kenli shore power project shows that as an enterprise in the field of power grid security and stability control, NR has made great support and positive contributions to the construction of major power projects in petrochemical industry. NR will continue to adhere to the corporate culture and work together to build on the past and open up the future, and protect the shore power access of CNOOC offshore oil and gas platforms from safe power supply to digital, unmanned and intelligent development, so as to contribute to promoting the high-quality development of the offshore oil industry and ensuring energy security.

Tingshan Frequency Converter Station of Hangzhou Flexible Low Frequency Transmission Pilot Project has been officially put into operation. It is the first time in the world to realize 220kV voltage level power frequency and low frequency controllable transformation. Flexible low-frequency transmission is a new type of AC transmission technology whose frequency is lower than the power frequency, which can effectively improve the transmission capacity, distance and efficiency of transmission lines. It has certain application advantages in medium and long distance offshore wind power transmission. Low-frequency transmission technology In order to optimize the power grid layout in Hangzhou, and explore the application prospect of flexible low-frequency transmission technology in urban high-density load areas, State Grid Zhejiang Company has planned and built Hangzhou flexible low-frequency transmission Pilot project in Hangzhou. Zhejiang Company has planned and built Hangzhou flexible low-frequency transmission Pilot project in Hangzhou The two high-voltage and high-capacity frequency converter stations in Tingshan and Zhongbu constructed in the project will form flexible low-frequency interconnection, which can realize flexible power flow mutual aid and asynchronous interconnection of the two major power grids in Fuyang and the south of Xiaoshan, improve the transmission capacity and flexibility of the two major power supply sections of 500kV Fuyang substation and 500kV Shengguang substation, improve the security and stability of the regional power grid. Low-frequency transmission project Tingshan Frequency Converter Station is the first high-voltage and high-capacity low-frequency converter station in the world, and also an important part of Hangzhou flexible low-frequency transmission project. The NR project team has tailored flexible low-frequency protection & control system, frequency conversion valve, low-frequency AC protection device, measuring equipment and other core complete sets of equipment for Tingshan frequency conversion station. In view of the high voltage and large capacity application scenario of Hangzhou Flexible Low Frequency Transmission Project, the project team put forward efficient start stop control strategy, steady state control strategy, low-frequency open phase operation control strategy, fault ride through strategy, frequency converter protection strategy and low-frequency AC protection scheme, which solved many problems such as low-frequency decoupling control, bridge arm balance control, fault current suppression, low-frequency open phase operation, etc. Advance power system NR has carried out fruitful research and exploration in the field of building an advance power system At the same time, the project team overcame the problems of synchronous pressurization of converter valve at power frequency and low-frequency, completed the insulation test between high-voltage and high-capacity frequency converter valve power frequency and low-frequency terminals for the first time. To build an advance power system with renewable energy as the main body has become the main development direction of the power industry. As a key high-tech enterprise, NR has carried out fruitful research and exploration in the field of building an advance power system. Flexible low-frequency equipment The complete set of flexible low-frequency equipment developed by NR has been successfully applied to Taizhou flexible low-frequency transmission project, and continues to serve the grid connected transmission of offshore wind power in Dachen Island. Hangzhou Flexible Low Frequency Power Transmission Project is an active attempt to apply flexible low frequency complete equipment to the construction of high elastic power grids in urban areas, and also provides a practical model for high-voltage and high-capacity offshore wind power transmission through low frequency. NR will continue to maintain high standards and quality to serve the project construction, give full play to its advantages, ensure the overall operation of the project, and continue to contribute to the construction of an advance power system.

Recently, Baihetan - Zhejiang ± 800kV UHV DC transmission project (referred as "Baizhe project") has been completed, and put into operation. The BaiZhe Project is a major clean energy project to promote the energy structure adjustment, energy conservation and emission reduction. It shoulders the strategic mission of delivering the power of the world's second largest hydropower station which is Baihetan hydropower station. New power giant dragon The project starts from Jinsha River converter station in Sichuan Province and ends at Qiantang River converter station in Zhejiang Province. It passes through five provinces, with a total length of 2121 km. The Jinsha River bank and the Qiantang River bank, thousands of miles away from the two places, are integrated together with the new power giant dragon.The project starts from Jinsha River converter station and ends at Qiantang River converter station NR has provided core equipment such as DC protection & control, converter valve, measurement, stability control, compressed air foam system (CAFS), intelligent auxiliary control system, AC protection and so on for the Baizhe Project. It has cooperated efficiently in various links such as equipment development, design, production, transportation, installation and commissioning to ensure the smooth operation of the project. Intelligent auxiliary control system The new generation of DC protection & control system based on the UAPC3.0 platform has been applied for the first time in the UHV project, and the new intelligent auxiliary control system has been deployed and promoted in the UHV converter station for the first time. The response speed, reliability, operation and maintenance intelligence of the protection & control system have been further improved. For the converter valve, the four-layer valve tower structure is newly designed, which greatly reduces the volume and weight of the valve tower on the premise of ensuring the safety of the equipment. Project implementation efficiency At the same time, a number of creative improvements have been made in the aspects of type test scheme At the same time, a number of creative improvements have been made in the aspects of type test scheme, valve tower maintenance, intelligent operation and maintenance of valve control, effectively improving the project implementation efficiency and equipment safety. In terms of stability control, the new generation of PCS-992 stability control system was first applied in the UHV project, and a system scheme of independently configuring stability control equipment for the high and low end power grid at the inverter side was proposed. The software design was optimized according to the DC equipment production timing and system operation mode, realizing the adaptive strategy function, and effectively improving the adaptability and reliability of the stability control system. Improving response speed In terms of CAFS, compressed air foam spray and fire monitor redundancy design are adopted. Meanwhile, device selection is optimized to improve response speed, fire resistance measures are strengthened to improve reliability, and safe operation of converter is ensured. The smooth operation of the Baizhe project once again reflects the technical advantages of NR's multi-disciplinary integration and the ability to implement major projects with efficient cooperation, and highlights the company's outstanding comprehensive strength in the field of high-end electric equipment. In the future, NR will continue to devote itself to the construction and development of DC transmission and make greater contributions to the optimization of the energy structure and the realization of the green power application worldwide.

On May 30, the first 100MWp tidal photovoltaics power station in China was connected to the grid with full capacity. This is the first time that China has complementary developed solar and tidal energy. The successful grid connection of this power station marks that China has made new achievements in the field of comprehensive utilization of marine energy. NR Electric provides a complete set of protection and monitoring equipment for the project, and implements the engineering integration of 110kV multi terminal differential (four terminal differential) line protection and 5MW/5MWh energy storage primary frequency modulation system. Frequency modulation system This project is the first PV power station in Zhejiang Province to synchronously constructe and install 5MW/5MWh energy storage system. Goose communication is used inside the energy storage system to realize the millisecond fast response The whole station has achieved a high level of automation. In conjunction with Zhejiang Electric Power Research Institute, the first photovoltaic power station fast frequency modulation pilot project was officially comissioned, which perfectly upgraded the coordination among energy storage, SVG and inverter. Goose communication is used inside the energy storage system to realize the millisecond fast response of primary frequency modulation with photovoltaics and energy storage. Power station reservoir area Zhejiang Wenling tidal PV Power Station is located in Jiangxia Tidal Power Station and Reservoir Area, Taizhou , Zhejiang. The total area of the reservoir area is about 1.33 km. The rated installed capacity is 100MWp. The project implements a new construction model of "new green energy tidal energy + solar energy", makes full use of the water surface of the power station reservoir area. After being connected to the grid, it is estimated that the annual average on-grid power generation will be about 106.87 million kWh, which will save 32,600 tons of standard coal every year.

On June 17, 2022, the world's first 35kV high-voltage direct coupled energy storage system developed by NR was successfully connected to the grid in Shaoxing Hongxu energy storage power station in China. It not only helps to achieve the efficient use of clean energy and promote the green and low-carbon transformation, but also enhances the flexible regulation capacity of the power grid. High voltage direct coupled energy storage not only reduces the electrical distance from the main grid, but also has the advantages of stronger grid support effect, response consistency and higher conversion efficiency. Energy storage batteries The smooth operation of the project helps to explore and establish the standard of advance energy storage technology, promote the energy storage system to move towards a higher voltage level, larger capacity, safer, more reliable and more efficient direction, and can adapt to the characteristics of multiple types of energy storage batteries, making a useful attempt for the development direction of energy storage. The whole system uses a cascade topology to distribute the batteries to each PCS module The whole system uses a cascade topology to distribute the batteries to each PCS module. The reliability of the whole energy storage system is effectively improved through the integrated closed self-circulation air cooling technology and online thermal redundancy technology. At the same time, the multi-level active equalization technology is used to greatly improve the utilization of the battery and eliminate the "short board effect" of the battery cluster. Green power systems NR has provided a complete set of solutions for Shaoxing 35kV high voltage direct coupled energy storage system, including energy management system (EMS), Power Management System (PMS), high and low voltage full series air / liquid cooled Power conversion system (PCS), and battery management system (BMS). NR will continue to do a good job in the exploration of new energy storage systems, promote the research and practice of grid-forming energy storage application, and make more contributions to the construction of green power systems.

On June 8, 2022, NR controlled switching device was successfully put into operation in Fengning pumped storage power station with the largest installed capacity in the world, which successfully ensured that the pumping and storage power station units were connected to Zhangbei flexible DC power grid. This is the first application of NR's controlled switching device in a large-scale pumped storage project. Fengning pumped storage power station is a key project serving the Beijing Winter Olympics to achieve 100% green power supply. It is the first time that the pumped storage power station connected to the flexible DC power grid, which provide a valuable solution to solve the problem of large-scale development and utilization of renewable energy. Transformer charging excitation Fengning pumped storage power station is known as the world's largest "super power bank", close to the core area of the 10 GW wind power base. The power station is equipped with 12 units, with a total installed capacity of 3.6 GW, an annual saving of 480,000 tons of standard coal and a reduction of 1.2 million tons of carbon dioxide emissions. NR has cooperated with customer to discuss the issues of main transformer charging excitation In order to reduce the impact of the main transformer switching of Fengning Pumped Storage Power Station on the flexible DC system in Zhangbei, NR has cooperated with customer to discuss the issues of main transformer charging excitation inrush current and voltage harmonics, and proposed a solution for adding controlled switching device on all 500kV transformer sides circuit breakers of pumped-storage power stations. Main transformer switching In order to meet the complex "pumped storage + flexible DC" excitation inrush current suppression requirements, NR has comprehensively considered factors such as the harsh working conditions of two main transformers in parallel, the mechanical dispersion of circuit breakers, transformer parameters, and remanence level. Before the main transformer was officially put into operation, a large amount of test data was collected, and simulation calculation research was fully carried out. The main transformer switching test of 1, 2, 9 and 10 units successfully suppressed the maximum inrush current from more than 1000A to less than 300A, effectively reducing the busbar voltage distortion and system harmonic content. The pumped-storage power station can be reliably integrated into the flexible DC grid under the impact disturbance of the main transformer switching. Advanced power system With the construction and development of an advance power system with a high proportion of renewable energy and power electronic device connected to the grid, the need for grid stability to suppress harmonics and disturbances has become prominent. As an important technical means to mitigate transient shocks, controlled switching technology will also face more opportunities and challenges. NR will continue to develop high-quality product and solution to make more efforts for power system reliability and flexibility.

Recently China’s largest offshore oilfield group using land grid power supply application project - CNOOC Bozhong-Kenli Oilfield Group Shore Power Application Demonstration Project in the Bohai Sea region was successfully put into operation. Bozhong Kenli Oilfield shore power project includes onshore 220kV Haiguo switching station, offshore 220kV Haitai electric power platform, 220kV Haimin electric power platform, 220kV Hai'an electric power platform and 110kV Haixiang electric power platform. With the successful power transmission of each substation, it marks that the offshore and onshore backbone parts of Bozhong Kenli shore power project of Bohai Oilfield have been completed as scheduled. High energy consumption Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development as fuel for power generation, which not only has low efficiency and high energy consumption, and the stability is far lower than that of the large power grid. Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development After the shore power project is put into operation, compared with the peak year of power generation, the natural gas consumption will be reduced by 1.5 billion m3, the annual energy saving will be nearly 650,000 tons and other standard coals, which is equivalent to reducing carbon dioxide emissions by 1 million tons. Secondary system equipment The successful operation of the project will further change the previous "self-generation mode" of China's offshore oil fields. It is of great strategic significance for China to promote the adjustment of the national energy structure, achieve the goal of energy conservation and emission reduction, promote the green development of offshore oil and gas fields. As the supplier of the overall secondary system equipment of the shore power project, NR has provided a full set of core equipment such as integrated automation system, dispatching system, centralized control center, protection equipment, safety and stability control system, excitation inrush current suppressor, etc. for the four 220kV substations and one 110kV substation of the project. Special offshore environment NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology At the beginning of the project, NR went deep into the unique characteristics of the power grid structure and operation & maintenance of the Bozhong Kenli shore power project, and carried out in-depth relevant system research, simulation calculation and scheme design with CNOOC. As all systems of the offshore electric power platform are in the special offshore environment of high humidity and salinity, all complete sets of equipment provided by NR have passed the acceptance of the classification society of the classification society company, fully meeting the long-term, high requirements and high standards of operation in the offshore environment. NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology, excellent products and professional services, providing strong support for the power network construction of the world's largest offshore oilfield group. Ensuring energy security The smooth operation of Bozhong Kenli shore power project shows that as an enterprise in the field of power grid security and stability control, NR has made great support and positive contributions to the construction of major power projects in petrochemical industry. NR will continue to adhere to the corporate culture and work together to build on the past and open up the future, and protect the shore power access of CNOOC offshore oil and gas platforms from safe power supply to digital, unmanned and intelligent development, so as to contribute to promoting the high-quality development of the offshore oil industry and ensuring energy security.

Tingshan Frequency Converter Station of Hangzhou Flexible Low Frequency Transmission Pilot Project has been officially put into operation. It is the first time in the world to realize 220kV voltage level power frequency and low frequency controllable transformation. Flexible low-frequency transmission is a new type of AC transmission technology whose frequency is lower than the power frequency, which can effectively improve the transmission capacity, distance and efficiency of transmission lines. It has certain application advantages in medium and long distance offshore wind power transmission. Low-frequency transmission technology In order to optimize the power grid layout in Hangzhou, and explore the application prospect of flexible low-frequency transmission technology in urban high-density load areas, State Grid Zhejiang Company has planned and built Hangzhou flexible low-frequency transmission Pilot project in Hangzhou. Zhejiang Company has planned and built Hangzhou flexible low-frequency transmission Pilot project in Hangzhou The two high-voltage and high-capacity frequency converter stations in Tingshan and Zhongbu constructed in the project will form flexible low-frequency interconnection, which can realize flexible power flow mutual aid and asynchronous interconnection of the two major power grids in Fuyang and the south of Xiaoshan, improve the transmission capacity and flexibility of the two major power supply sections of 500kV Fuyang substation and 500kV Shengguang substation, improve the security and stability of the regional power grid. Low-frequency transmission project Tingshan Frequency Converter Station is the first high-voltage and high-capacity low-frequency converter station in the world, and also an important part of Hangzhou flexible low-frequency transmission project. The NR project team has tailored flexible low-frequency protection & control system, frequency conversion valve, low-frequency AC protection device, measuring equipment and other core complete sets of equipment for Tingshan frequency conversion station. In view of the high voltage and large capacity application scenario of Hangzhou Flexible Low Frequency Transmission Project, the project team put forward efficient start stop control strategy, steady state control strategy, low-frequency open phase operation control strategy, fault ride through strategy, frequency converter protection strategy and low-frequency AC protection scheme, which solved many problems such as low-frequency decoupling control, bridge arm balance control, fault current suppression, low-frequency open phase operation, etc. Advance power system NR has carried out fruitful research and exploration in the field of building an advance power system At the same time, the project team overcame the problems of synchronous pressurization of converter valve at power frequency and low-frequency, completed the insulation test between high-voltage and high-capacity frequency converter valve power frequency and low-frequency terminals for the first time. To build an advance power system with renewable energy as the main body has become the main development direction of the power industry. As a key high-tech enterprise, NR has carried out fruitful research and exploration in the field of building an advance power system. Flexible low-frequency equipment The complete set of flexible low-frequency equipment developed by NR has been successfully applied to Taizhou flexible low-frequency transmission project, and continues to serve the grid connected transmission of offshore wind power in Dachen Island. Hangzhou Flexible Low Frequency Power Transmission Project is an active attempt to apply flexible low frequency complete equipment to the construction of high elastic power grids in urban areas, and also provides a practical model for high-voltage and high-capacity offshore wind power transmission through low frequency. NR will continue to maintain high standards and quality to serve the project construction, give full play to its advantages, ensure the overall operation of the project, and continue to contribute to the construction of an advance power system.

Recently, Baihetan - Zhejiang ± 800kV UHV DC transmission project (referred as "Baizhe project") has been completed, and put into operation. The BaiZhe Project is a major clean energy project to promote the energy structure adjustment, energy conservation and emission reduction. It shoulders the strategic mission of delivering the power of the world's second largest hydropower station which is Baihetan hydropower station. New power giant dragon The project starts from Jinsha River converter station in Sichuan Province and ends at Qiantang River converter station in Zhejiang Province. It passes through five provinces, with a total length of 2121 km. The Jinsha River bank and the Qiantang River bank, thousands of miles away from the two places, are integrated together with the new power giant dragon.The project starts from Jinsha River converter station and ends at Qiantang River converter station NR has provided core equipment such as DC protection & control, converter valve, measurement, stability control, compressed air foam system (CAFS), intelligent auxiliary control system, AC protection and so on for the Baizhe Project. It has cooperated efficiently in various links such as equipment development, design, production, transportation, installation and commissioning to ensure the smooth operation of the project. Intelligent auxiliary control system The new generation of DC protection & control system based on the UAPC3.0 platform has been applied for the first time in the UHV project, and the new intelligent auxiliary control system has been deployed and promoted in the UHV converter station for the first time. The response speed, reliability, operation and maintenance intelligence of the protection & control system have been further improved. For the converter valve, the four-layer valve tower structure is newly designed, which greatly reduces the volume and weight of the valve tower on the premise of ensuring the safety of the equipment. Project implementation efficiency At the same time, a number of creative improvements have been made in the aspects of type test scheme At the same time, a number of creative improvements have been made in the aspects of type test scheme, valve tower maintenance, intelligent operation and maintenance of valve control, effectively improving the project implementation efficiency and equipment safety. In terms of stability control, the new generation of PCS-992 stability control system was first applied in the UHV project, and a system scheme of independently configuring stability control equipment for the high and low end power grid at the inverter side was proposed. The software design was optimized according to the DC equipment production timing and system operation mode, realizing the adaptive strategy function, and effectively improving the adaptability and reliability of the stability control system. Improving response speed In terms of CAFS, compressed air foam spray and fire monitor redundancy design are adopted. Meanwhile, device selection is optimized to improve response speed, fire resistance measures are strengthened to improve reliability, and safe operation of converter is ensured. The smooth operation of the Baizhe project once again reflects the technical advantages of NR's multi-disciplinary integration and the ability to implement major projects with efficient cooperation, and highlights the company's outstanding comprehensive strength in the field of high-end electric equipment. In the future, NR will continue to devote itself to the construction and development of DC transmission and make greater contributions to the optimization of the energy structure and the realization of the green power application worldwide.

On May 30, the first 100MWp tidal photovoltaics power station in China was connected to the grid with full capacity. This is the first time that China has complementary developed solar and tidal energy. The successful grid connection of this power station marks that China has made new achievements in the field of comprehensive utilization of marine energy. NR Electric provides a complete set of protection and monitoring equipment for the project, and implements the engineering integration of 110kV multi terminal differential (four terminal differential) line protection and 5MW/5MWh energy storage primary frequency modulation system. Frequency modulation system This project is the first PV power station in Zhejiang Province to synchronously constructe and install 5MW/5MWh energy storage system. Goose communication is used inside the energy storage system to realize the millisecond fast response The whole station has achieved a high level of automation. In conjunction with Zhejiang Electric Power Research Institute, the first photovoltaic power station fast frequency modulation pilot project was officially comissioned, which perfectly upgraded the coordination among energy storage, SVG and inverter. Goose communication is used inside the energy storage system to realize the millisecond fast response of primary frequency modulation with photovoltaics and energy storage. Power station reservoir area Zhejiang Wenling tidal PV Power Station is located in Jiangxia Tidal Power Station and Reservoir Area, Taizhou , Zhejiang. The total area of the reservoir area is about 1.33 km. The rated installed capacity is 100MWp. The project implements a new construction model of "new green energy tidal energy + solar energy", makes full use of the water surface of the power station reservoir area. After being connected to the grid, it is estimated that the annual average on-grid power generation will be about 106.87 million kWh, which will save 32,600 tons of standard coal every year.

On June 17, 2022, the world's first 35kV high-voltage direct coupled energy storage system developed by NR was successfully connected to the grid in Shaoxing Hongxu energy storage power station in China. It not only helps to achieve the efficient use of clean energy and promote the green and low-carbon transformation, but also enhances the flexible regulation capacity of the power grid. High voltage direct coupled energy storage not only reduces the electrical distance from the main grid, but also has the advantages of stronger grid support effect, response consistency and higher conversion efficiency. Energy storage batteries The smooth operation of the project helps to explore and establish the standard of advance energy storage technology, promote the energy storage system to move towards a higher voltage level, larger capacity, safer, more reliable and more efficient direction, and can adapt to the characteristics of multiple types of energy storage batteries, making a useful attempt for the development direction of energy storage. The whole system uses a cascade topology to distribute the batteries to each PCS module The whole system uses a cascade topology to distribute the batteries to each PCS module. The reliability of the whole energy storage system is effectively improved through the integrated closed self-circulation air cooling technology and online thermal redundancy technology. At the same time, the multi-level active equalization technology is used to greatly improve the utilization of the battery and eliminate the "short board effect" of the battery cluster. Green power systems NR has provided a complete set of solutions for Shaoxing 35kV high voltage direct coupled energy storage system, including energy management system (EMS), Power Management System (PMS), high and low voltage full series air / liquid cooled Power conversion system (PCS), and battery management system (BMS). NR will continue to do a good job in the exploration of new energy storage systems, promote the research and practice of grid-forming energy storage application, and make more contributions to the construction of green power systems.

On June 8, 2022, NR controlled switching device was successfully put into operation in Fengning pumped storage power station with the largest installed capacity in the world, which successfully ensured that the pumping and storage power station units were connected to Zhangbei flexible DC power grid. This is the first application of NR's controlled switching device in a large-scale pumped storage project. Fengning pumped storage power station is a key project serving the Beijing Winter Olympics to achieve 100% green power supply. It is the first time that the pumped storage power station connected to the flexible DC power grid, which provide a valuable solution to solve the problem of large-scale development and utilization of renewable energy. Transformer charging excitation Fengning pumped storage power station is known as the world's largest "super power bank", close to the core area of the 10 GW wind power base. The power station is equipped with 12 units, with a total installed capacity of 3.6 GW, an annual saving of 480,000 tons of standard coal and a reduction of 1.2 million tons of carbon dioxide emissions. NR has cooperated with customer to discuss the issues of main transformer charging excitation In order to reduce the impact of the main transformer switching of Fengning Pumped Storage Power Station on the flexible DC system in Zhangbei, NR has cooperated with customer to discuss the issues of main transformer charging excitation inrush current and voltage harmonics, and proposed a solution for adding controlled switching device on all 500kV transformer sides circuit breakers of pumped-storage power stations. Main transformer switching In order to meet the complex "pumped storage + flexible DC" excitation inrush current suppression requirements, NR has comprehensively considered factors such as the harsh working conditions of two main transformers in parallel, the mechanical dispersion of circuit breakers, transformer parameters, and remanence level. Before the main transformer was officially put into operation, a large amount of test data was collected, and simulation calculation research was fully carried out. The main transformer switching test of 1, 2, 9 and 10 units successfully suppressed the maximum inrush current from more than 1000A to less than 300A, effectively reducing the busbar voltage distortion and system harmonic content. The pumped-storage power station can be reliably integrated into the flexible DC grid under the impact disturbance of the main transformer switching. Advanced power system With the construction and development of an advance power system with a high proportion of renewable energy and power electronic device connected to the grid, the need for grid stability to suppress harmonics and disturbances has become prominent. As an important technical means to mitigate transient shocks, controlled switching technology will also face more opportunities and challenges. NR will continue to develop high-quality product and solution to make more efforts for power system reliability and flexibility.

Expert Commentary

Fleet electrification provides opportunities to achieve climate goals while delivering social, financial, and environmental benefits to individuals, businesses, and communities, but the road to successful EV implementation is not without obstacles. Your EV fleets need to work — all the time under varying conditions — to ensure optimal uptime while maintaining energy efficiency. Consequently, electric vehicle service equipment (EVSE) can’t just be “tacked onto” your existing operation. Rather than a “new standalone addition,” it requires a thoughtful and forward-looking approach to seamlessly integrate into your overall facility. Ensuring the type of reliable power needed for an electrified fleet is critical. Luckily, there are a number of new and emerging solutions that promise to deliver clean and reliable local power generation. The Challenges The availability and reliability of the power needed to support electrified fleets is a primary roadblock for many commercial fleet operators. It’s important to look at where that power comes from, how much it will cost, and whether it will be available when needed. Projections indicate that the demand for electricity will surge by 50% during the next two decades Today’s energy landscape is complex. Projections indicate that the demand for electricity will surge by 50% during the next two decades, with no signs of slowing down. According to Grid Strategies, the U.S. electric grid is not prepared for this level of significant load growth. The sheer amount of power needed to keep trucks charged and running 24/7 can be substantial. This poses a key risk for reliability in EV infrastructures, particularly in mission-critical situations. In addition, most fleet operators have become accustomed to fairly predictable fuel costs, since many take advantage of long-term supply arrangements. By contrast, electricity grid costs can vary and result in unpredictable spikes. This adds an extra layer of complexity when it comes to the planning and timing of fleet charging. As a result, many fleet charging operations are turning to local power generation. Intelligent Microgrids, the Energy Insurance Microgrids are nothing new, with rural communities relying on them for decades. Increased affordability and shifting regulations are allowing for more of these microgrids to be powered by renewable energy methods. A common misconception is that microgrids can completely off-set power from the grid. In reality, they are designed to provide peak load shaving and system resiliency. Coupled with an EV infrastructure, microgrids can offer more flexible and reliable energy management. When compared to a traditional microgrid for a building system, microgrids for fleet electrification present new challenges. Most notably, microgrids for fleet electrification are not modeled on an existing load, but rather anticipated demand, which can make reliable load-based modeling more difficult. However, an "intelligent" microgrid uses control systems to manage, store, charge, and discharge energy across the system. Strategic energy management The system can buy power from the grid during low-cost periods while storing self-generated solar power These controls monitor supply and demand, track real-time electricity prices, and create efficient charging schedules, considering factors like Time of Use (TOU) and peak day rates. For example, when electric fleets plug in, demand may increase significantly overnight, making strategic energy management crucial. The system can buy power from the grid during low-cost periods while storing self-generated solar power for later use. When prices rise, it discharges stored energy, keeping costs stable. It can also operate independently, ensuring continuous power during outages and disruptions, improving efficiency, cost control, and reliability. Conversely, fleets often permit charging flexibility within defined boundaries, providing a unique dispatchable resource that can be tuned to fit the needs and energy resources of the customer. A New Category of Local Power Generation Linear generator technology is proving to be an innovative solution for EV infrastructures by providing flexible, resilient and cost-effective on-site base load power. Linear generator technology provides fuel-flexibility meaning they can directly run and switch among traditional fuels like natural gas or propane. Or, they can use low and zero-carbon fuels such as RNG, biogas, hydrogen, and ammonia. Its backup capabilities ensure power through hurricanes, sub-zero snowstorms, excessive heat, and other extreme conditions. Based on capex and operating costs, linear generators can provide a competitive levelized cost of ownership compared to grid power or other alternatives in certain regions. Net-zero goals These solutions allow for flexibility and integration of new fuels as they become available The technology can also be quickly deployed at scale, which is ideal for large fleet operators looking to quickly and cost-effectively deploy resilient EV charging infrastructure while reducing emissions and working toward net-zero goals. What’s more, linear generators deliver a more “future-proof” path. While the dominant sources of fuel for local power generation today is well understood, new and exciting fuels are on the horizon. These solutions allow for flexibility and integration of new fuels as they become available. All without having to replace or retrofit existing equipment. Experts Will Power the Future As companies look to integrate EVs into their operations, a well-thought-out plan for infrastructure is essential to ensure safety, reliability, and long-term success. The integration of onsite power systems will play a critical role in optimizing energy use, lowering costs, and maintaining system resilience. The good news is that energy management is becoming more flexible, ensuring that fleet electrification is not only sustainable but also cost-effective. To ensure a seamless transition and maximize the benefits of fleet electrification, many companies will be moving forward by working with experienced consultants and planners to create a future-proof infrastructure that meets both operational and environmental goals.

The promise of electric vehicles is closer to reality than ever before. New plans and investments at the federal level designate billions of dollars to move our country toward clean energy, including $2 million to help auto manufacturers retool facilities to increase EV production. Additionally, the Biden Administration has announced a goal to create 100% carbon-free electricity by 2035 and a net-zero carbon economy by 2050. Domestic EV marketplace The domestic EV marketplace has grown from 16,000 to more than 2 million vehicles in the last decade and is poised to expand at lightning speed over the next ten years. S&P Global mobility has predicted that by 2030, electric vehicles (EVs) will make up 40% of the U.S. market share of new vehicles on the road. This dramatic increase in EVs will require a nationwide network of charging stations to meet the demand from the current 140,000 to over 1.1 million. Charging stations It is a necessity that regulators lay the groundwork now for a reliable and secure charging networkThe expansion of charging stations will undoubtedly give zero-emissions drivers more confidence in their ability to refuel more conveniently. Still, it’s critical that confidence in infrastructure security also be prioritized alongside this growth. If not adequately protected and monitored, charging stations could serve as access points for cybercriminals, potentially leading to personal data leaks, attacks on vehicle systems, and even widespread blackouts. As EVs continue to gain momentum as realistic alternatives to CO-2 emitting vehicles, it is a necessity that developers and regulators lay the groundwork now for a reliable and secure charging network for the long term. EV Charging Infrastructure and the electric grid The nation’s electric grid generates and delivers electricity essential to everyday life. It’s made up of power plants and other sources of generated electricity, complete with transmission and distribution lines and infrastructure that delivers essential power. Grid connection An important aspect to remember about EV charging stations is that they connect to their relative electric grid. Simply put, the infrastructure for charging stations is comprised of devices that wait for another device to connect and communicate. However, it lacks a third-party firewall or other devices that can act as protection. Unfortunately, this results in vulnerability and means new doors for cybercriminals to walk through. Cybersecurity risks If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts Even before EV charging stations are factored in, the electric grid faces substantial cybersecurity risks from criminals, terrorists, hackers, and foreign governments every day. If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts that would undoubtedly affect EV charging stations and other essential institutions such as banks, hospitals, and gas stations. With the expansion of EV charging stations, the risks only grow. Now is the time to address threats and strategize before disaster strikes. Risks of connectivity emerge The world we live in has reached a level of being almost entirely connected at all times – security systems, appliances, health monitors, industrial sensors, and now, our vehicles. While the connectivity of vehicles has been incredibly beneficial to consumers and the automotive industry alike, the growth in the internet of things (IoT) has opened countless doorways for cybersecurity threats. Software flaws One young information technology security specialist reported finding flaws within a third-party software that a handful of leading EV manufacturers use. It gave him access to more than 25 EVs in at least 13 countries. The man, who stumbled on the findings in 2022, said he could remotely control some EV functions, including starting vehicles, unlocking windows and doors, disabling security systems, and turning on stereo systems and flashing headlights. The IT specialist said he could also tell if a person was in the vehicle. In a separate and concerning situation, a single compromised password led to a foreign-fronted cyberattack on a U.S.-based pipeline in 2021. It halted the fuel supply process on the east coast and cost the company $4.4 million in ransom money. Cyberattacks Thousands of charging stations are already in danger of being targeted by cybercriminals The point is that even massive and powerful companies can fall victim to cyberattacks. Even though cybersecurity is a critical issue for EV manufacturers, their systems are still vulnerable to hackers. Thousands of charging stations are already in danger of being targeted by cybercriminals, and as the number of stations grows, so too will the risk. The higher the number of entry points, the more opportunities hackers will see. If they can break into and gain access to even the most sophisticated EVs, it could be catastrophic. Ensuring security and reliability through proactivity Because charging stations are connected to the country’s primary grid, the entire infrastructure must be armed with the most aggressive security measures. The risks associated with modernized electric vehicles are not something that traditional automotive safety regulations and security standards properly cover. The complicated and rapid evolution of EVs is putting them at a heightened threat. When charging stations are connected to the electrical grid, it is imperative to ensure strong cybersecurity measures are in place to remain dependable and effective. Embedding cybersecurity technology We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection The best way to ensure the electric grid's safety is to build cybersecurity technology directly into the charging stations. We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection. Unfortunately, the promising growth EVs and their charging stations bring to our environment also contributes to technology’s vulnerabilities, which can cause key security measures to be overlooked. There’s no getting around it: EV charging stations are highly vulnerable to hackers. Awareness and solutions As the growth continues, there is an acute need for heightened awareness and solutions for the weaknesses associated with these charging stations. These solutions should consider everything from the charging points and devices to operators of the energy distribution networks and infrastructure providers. We must aim to implement advanced cybersecurity measures that will keep safe drivers and all the data that EVs contain.

As the demand for power increases in the UK across growing domestic and industrial markets including the nuclear industry, so the need for reliable power generation, transmission, and distribution using Medium Voltage cables has risen with it. The demands for power has never been greater, with the explosion of development in towns and cities across the UK and the growth of industrial development and technology reliant on consistent supplies. Medium voltage cables As the incidence of non-approved cables continues, Medium Voltage (MV) cables coming onto the market should be independently approved and certified as compliant as the pressure mounts on the installation of quality products in modern building developments. Indeed, new demands are being placed on the grid continually for reliable supplies and the development of nuclear plants at sites including Sellafield and Capenhurst only increases that need for reliable supply using approved products throughout the supply chain. New demands are being placed on the grid continually for reliable supplies The supply chain should be particularly careful around the application of these cables into such high-risk environments as these as well as hospitals, major industrial sites and sub-stations serving infrastructure sites. MV cables are crucial to our infrastructure. Electricity leaves the generating site and is routed via a step-up transformer to take it up to the National Grid distribution voltages of 400Kv, 275Kv, and 132Kv. Once in the local area, the supply goes through step-down transformers that reduce the voltage to 415V with domestic supplies tapped off at 230V. Large volumes of power To facilitate moving electricity around the National Grid, there are almost 4,500 miles of overhead lines, almost 1,000 miles of underground cables, and 342 Grid substations. Once stepped down, power is then distributed on local networks at a lower voltage, commonly 66Kv,33Kv, and 11Kv. In all, there are 14 licensed District Network Operators (DNOs). Very often, the supply of power to consumers of large volumes of electricity is routed via sub-stations to feed large sites such as industrial installations, hospitals, and educational institutions. To provide power to the sub-stations - very often located on the premises of the establishment that they supply - Medium Voltage (MV) cables are used. MV cables were only developed as the level of voltages increased and the need arose for a greater classification range. A developing market The size of the market has developed to the point where the global MV cables market was valued at $39.31 billion in 2016 and is projected to grow at a rate of more than six percent until 2022. The technical design and specification of the cables themselves are of paramount importance within the power distribution network. The AEI Cables range of MV cables meet all requirements of BS6622, BS7835, and IEC60502-2 and are all approved and certified by third-party approval organization BASEC for ranges up to 33kV. There are a number of technical considerations to be taken into account including the size of the installation, the position of the installation in relation to the network, and the presence of primary and secondary sub-stations. Non-approved cabling Prior to installation, a detailed route survey should also be carried out to plan where cables will be joined and to identify any possible obstructions which may require special civil engineering works such as directional drilling. Underlying the critical nature of supplies to these types of services, the incidence of non-approved cables continues, so the application of MV cables into these important and sensitive environments becomes critical. In these environments, it is even more crucial to get it right the first time There have been many instances in the recent past of non-approved cables coming onto the market, but in these environments it is even more crucial to get it right the first time, thereby reducing the risk and the cost of anything going wrong. Look for the British Standard, European or international standard number, the manufacturer’s mark, and third-party approval markings. Even if there are markings, it is worth checking because some labels and stamps have been used fraudulently. Cables can become untraceable Cables that are unmarked but not checked can become untraceable so it is important at the point of receipt for contractors to check every time. Also, keep records of purchase and delivery to ensure that what is being installed is what was specified originally. It is well worth the small amount of time to make these checks, especially as these cables are buried and relied on to provide a continuous power supply. In a number of instances, cables are even being laid under the sea to avoid lengthy and costly delays in seeking permission from landowners. Some cables are provided with an armored layer to help protect them against damage whether installed below or above ground, generally for industrial applications. Armoring also protects a cable during storage, transport to site, and installation. Metallic armoring is always earthed at one or more points in the circuit and may therefore contribute as a protective conductor to carry earth fault current. Extensive testing Modern polymeric-insulated LV and MV cables designed for UK utility use are usually not armored but have a concentric layer of copper wires under the outer sheath. Faults in underground cables are very expensive to repair, especially cables installed under roads and pavements. Repairing a fault will probably involve cutting out a length of cable on either side of the fault and installing a new length together with joints to connect to the existing cable. MV cables are subjected to extensive testing of material components and electrical tests including AC voltage and partial discharge. MV cables are subjected to extensive testing of material components and electrical tests Supplying industries At AEI Cables, we supply products to the construction, industrial, fire protection, defense, mining, and rail industries worldwide meeting the requirements for MV cables to BS 6622 and BS7835 and the highest relevant industry standards including ISO 9001 ISO 14001, and ISO 18001 for ranges up to 500kV. These products are also approved by leading independent approvals organizations nationally and internationally including BASEC, LPCB, and Lloyds. Third-party approval verifies that they can pass rigorous testing in the conditions in which they will operate. The demand continues for MV cables of quality which can consistently supply power to meet the growing challenge in whatever form it is presented.

Power Beat

The electrical industry is expected to have a labor shortage of about 60,000 workers by 2026. A labor shortage in the electrical trade is not inevitable, but it is likely to continue if the industry does not take steps to address the issue. Like other skilled trades, the electrical industry is facing challenges that could contribute to a labor shortage, including an aging workforce, a lack of interest among younger generations, and competition from other industries. However, there are strategies the industry can implement to address these challenges and attract a new generation of workers. These strategies include increasing awareness of the benefits and opportunities of skilled trades, investing in training and education programs, improving working conditions and compensation, embracing technology, promoting diversity and inclusivity, and collaborating among industry, education, and government. Improving working conditions Factors in the current labor shortage in the electrical industry include: Aging workforce: Many workers in the electrical industry are nearing retirement age, and there are not enough younger workers to replace them. This has led to a shortage of skilled workers with many years of experience in the industry. Lack of interest in the trades: There has been a decline in the number of young people pursuing careers in the skilled trades, including electrical work. This is due in part to a focus on four-year college degrees as the preferred career path, as well as a lack of awareness of the benefits and opportunities of skilled trades. Competition from other industries: The electrical industry is competing with other industries, such as construction and manufacturing, for skilled workers. Training and education: Training and education are critical for developing the skills and knowledge necessary for electrical work. However, there is a shortage of qualified trainers and educators. Increasing demand: The demand for electrical services is increasing, particularly in areas such as renewable energy and smart grid technology. Attracting and retaining workers To attract and retain workers, the electrical industry must offer competitive wages and benefits One strategy to address the labor shortage is to increase awareness of skilled trades and to promote the benefits of a career in the electrical industry through outreach programs in schools, career fairs, and other events. Providing access to quality training and education programs that develop the skills and knowledge necessary for electrical work is crucial for attracting and retaining workers. This can be done through apprenticeship programs, vocational schools, and community colleges. To attract and retain workers, the electrical industry must offer competitive wages and benefits, as well as a safe and supportive work environment. This includes offering training and development opportunities, flexible schedules, and opportunities for advancement. Inclusive work environment The electrical industry is changing rapidly, and workers must be equipped with the latest technology and tools to stay competitive. Providing workers with training and access to the latest technology can help attract and retain workers. The electrical industry should actively promote diversity and inclusivity to attract a wider pool of workers. This includes efforts to recruit workers from underrepresented groups and create a welcoming and inclusive work environment. The electrical industry is changing rapidly, and workers must be equipped with the latest technology Companies in the electrical industry are addressing the labor shortage problem by investing in workforce development programs and initiatives. For example, Schneider Electric has developed a comprehensive workforce development program called the Schneider Electric Energy and Automation Training (SEAT) program. The SEAT program provides training and certification for employees, customers, and partners in areas such as energy management, automation, and digital transformation. Developing training programs Siemens has developed several initiatives to address the labor shortage in the electrical industry. These initiatives include apprenticeship programs, vocational training programs, and partnerships with educational institutions to develop training programs. Graybar, a distributor of electrical products and solutions, has developed a workforce development program called Graybar University to provide training and education for employees, customers, and partners in areas such as lighting, automation, and safety. Joint apprenticeship training program Collaboration among industry, education, and government is crucial for developing solutions The International Brotherhood of Electrical Workers (IBEW) and the National Electrical Contractors Association (NECA) have developed a joint apprenticeship training program that provides training and education for individuals looking to enter the electrical industry. The program provides on-the-job training and education in areas such as electrical theory, safety, and installation. Collaboration among industry, education, and government is crucial for developing solutions to the labor shortage in the electrical industry. This includes partnerships between industry and education institutions to provide training and education programs, as well as government initiatives to support workforce development in the skilled trades.

Case studies

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.

Jenkins sold a Jenkins Motor Test System to Oman, where temperatures can exceed 120ºF. While Jenkins Motor Test Systems are built tough and for industrial environments, this specific location required customizations to be the most effective in an extremely hot environment. Locations near large bodies of water or tropical environments can also cause problems as the humidity in the air will cause the copper wiring in the transformer to oxidize over time. Although Jenkins designs its equipment to operate for long periods, some applications for customer environments require specific customization. The Solution Jenkins engineers and winders worked together to develop a custom solution for this harsh climate, particularly paying close attention to temperature and water resistance. To customize the transformer for this environment, the Jenkins team made the following modifications: Doubling the spacing between winding layers to increase airflow. Encasing the transformer first in a high tolerance epoxy varnish, and then in a polyester over-dip that prevents the application from rust, dust, and harmful materials. Utilizing expanded metal at the base of the MTS enclosure, allows heat to escape, reducing the internal temperature. Installing temperature-sensitive cooling fans (set to 100ºF) atop the enclosure to prevent overheating. The Results Jenkins technicians checked insulation for 10,000 volts (resistance to ground), checked each voltage leg, and high voltage potential to ground, and ensured the taps were in the correct place. Voltage was confirmed to operate up to 20% above normal operation, ensuring maximum efficiency and longevity of the transformer. These modifications have resulted in prolonged use of the Jenkins Motor Test System in harsh environments and ultimately customer satisfaction.

Fluence Energy, Inc., a global provider of energy storage products, services, and optimization software for renewables and storage, announces that the company has been selected by Origin Energy Limited (Origin) to deliver a 300 MW / 650 MWh battery at the Mortlake Power Station in southwest Victoria. The project will use Fluence’s Gridstack™ energy storage product with a 15-year service agreement contributing to Origin’s strategy to accelerate renewable energy and energy storage in its portfolio. The system will also utilize Fluence’s AI-powered asset performance management (APM) software, Nispera™, to optimize the battery’s operational performance. Energy storage projects The system will capture excess power during periods of high renewable generation “We are honored to be selected by Origin to deliver this grid-forming battery-based energy storage system and deploy our ecosystem of solutions,” said Fluence President and Chief Executive Officer, Julian Nebreda. Julian Nebreda adds, “Australia is an important market for Fluence. Our local team is now delivering over 1 GW energy storage projects within Australia to enhance grid stability and enable the country’s clean energy transition.” Energy storage system to be commissioned in late 2026 The site preparation and civil works of the Mortlake Battery are expected to commence following a period of detailed design and procurement activity. The energy storage system is anticipated to be commissioned in late 2026. Located in Victoria’s South West Renewable Energy Zone, this energy storage system will provide system strength to the grid. The system will capture excess power during periods of high renewable generation and discharge to meet peak demand.

As part of a long-term modernization project at the Baltimore Washington International (BWI) Airport, Helios Electric was retained to perform design-assist, system integration, and on-site field engineering services. The project involved replacing an existing 7.5/10.5 MVA outdoor substation transformer and performing retrofit services at the corresponding medium-voltage switchgear lineups. The project also included enhancements to the electrical system protection since power reliability was deemed vital for airport operations. SEL-787 transformer protection relay A new SEL-787 transformer protection relay was installed to perform advanced transformer monitoring, controls, and system protection. New pilot control devices were installed on the corresponding switchgear lineups to indicate transformer faults, alarms, and mechanical conditions. Vacuum circuit breakers at the existing switchgear lineups were retained and modified to establish connectivity with the new substation transformer and the new transformer protection relay. transformer protection functions This installation approach yielded improved protection for the new transformer while limiting the scope, budget, duration, and power outages required to accomplish the necessary tasks. The improved transformer protection functions included the following: ANSI-87 – Current Differential Protection ANSI-87G – Restricted Earth Fault Protection ANSI-50/51 – Phase Overcurrent Protection (Backup) ANSI-50/51G – Ground Overcurrent Protection (Backup) ANSI-63 – Transformer Sudden Pressure ANSI-71 – Transformer Low Oil Level ANSI-49 – Transformer High Winding Temperature ANSI-26 – Transformer High Oil Temperature AC/DC control modifications To fulfill the customer’s desired requirements, the Helios Electric team investigated the internal circuitry of the switchgear lineups and ascertained the specific AC/DC control modifications required at the existing. Work performed under this project included the following: Examining and analyzing the components and sub-components of the existing switchgear lineups. Tracing the existing 35kV-class and 15kV-class vacuum circuit breakers to determine the existing field configuration. Developing modified equipment shop drawings for approval, construction, and as-built conditions. Programming and configuration of SEL-787 Transformer Protection Relay to establish system protection, controls, and integration with the facility’s Supervisory Control and Data Acquisition (SCADA) System. Installing and modifying existing 35kV-class and 15kV-class vacuum circuit breaker controls to accommodate the new substation transformer and transformer protection relay. Developing Operation & Maintenance (O&M) manuals for modified electrical equipment lineups. On-site electrical equipment training for airport maintenance personnel.