Energy Storage

Allianz Engineering has introduced a new inspection service for solar photovoltaic (PV) systems, aimed at businesses and industrial sites. As the UK ramps up its use of solar energy, spurred by government incentives and growing public interest in sustainability, regular inspections are becoming increasingly important. This new service extends the existing ‘Electrical Fixed Wiring Inspection’ to include regular checks and tests for solar PV systems. It can be used alone or alongside...

TE Connectivity, a world pioneer in connectors and sensors, has reduced Scope 1 and 2 greenhouse gas emissions by 80% between September 2020 and October 2024, outperforming its goal of a 70% reduction. This milestone is one example of the company's significant progress toward its long-term sustainability ambitions, detailed in its annual One Connected World corporate responsibility report. Focus on energy efficiency "Our corporate responsibility ambitions align with the expectations...

FPT Industrial, the Iveco Group brand dedicated to the design, production, and sale of powertrains and solutions for on- and off-road vehicles, as well as marine and power generation applications, will be heading to Dubai to exhibit at Middle East Energy, one of the most reputable and long-established events in the energy industry, being held from April 7 to 9. The brand will be present alongside its distributor network at Booth S2.C40, showcasing a selection of its offerings for the power gene...

Delta, a global pioneer in power management and smart green solutions, highlighted at Hannover Messe 2025 a versatile set of AI-driven smart manufacturing, energy infrastructure, and data centre solutions. These include, the award-winning D-Bot series cobots, featuring advanced cognitive capabilities and integration with NVIDIA Omniverse to develop next-generation digital twins; and DeltaGrid®, the AI-enabled energy management platform to optimize efficiency in the energy infrastructure sup...

On January 20, 2022, the first converter valve of the China Great Bay Area DC back-to-back project was successfully put into operation for the first time, marking an important step forward for the interconnection of the core areas of the Eastern and Western Pearl River Delta of the Guangdong power grid. The converter valves were supplied by NR. Unit 1 on the East side of Guangzhou took the lead in entering the system commissioning stage among the four units of the whole project, creating a new...

Luxi Island microgrid system, which was designed, supplied, commissioned and delivered by NR, has been successfully put into operation. The system effectively solved the black start problem of 10kV feeder level microgrid with impulsive load, and has won high recognition from users with an advanced and intelligent control strategy, a stable and reliable microgrid system. Power supply of Luxi Island The power supply of Luxi Island was transmitted remotely by submarine cables Luxi Island is loc...

News

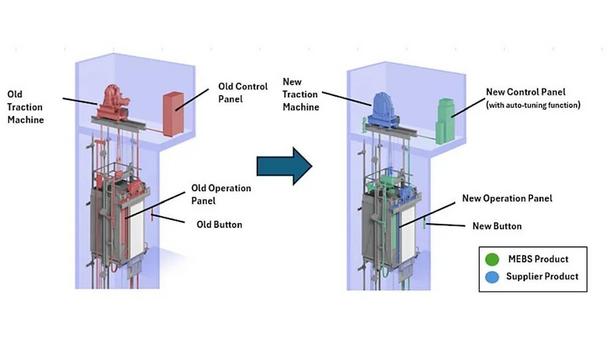

Mitsubishi Electric Building Solutions Corporation (MEBS, Head Office: Chiyoda-Ku, Tokyo; President: Iwao Oda) announced the launch scheduled for 19 March of a new overseas control renewal menu for elevators made by other companies installed in existing buildings. By developing a new control panel with an auto-tuning function, MEBS will respond to the diverse needs of its overseas customers for the renewal of control systems for elevators, while spurring the expansion of its maintenance and renewal business. Main Features of Renewal Menu 1) Achieving control that maximizes ride comfort even with other companies' traction machines through auto-tuning It is possible to upgrade to the latest control system by utilizing an MEBS control panel together with a traction machine made by another company. The newly developed control panel equipped with an auto-tuning function estimates the characteristics of the other company’s traction machine and automatically derives the control parameters for the combination of the other company’s traction machine and the MEBS control panel. This eliminates the need to develop a dedicated control panel for the traction machine and improves ride comfort. 2) Improving safety and contributing to sustainability by promoting the renewal of existing elevators The renewal menu promotes the renewal of existing elevators to improve safety and convenience, and contributes to sustainability by reducing power consumption and waste emissions through the reuse of some of the equipment. The menu also reduces downtime by eliminating the need to replace all of the equipment. 3) Achieving improved convenience in response to diversifying building solution needs By adopting the renewal menu, it is possible to introduce integrated building solutions utilizing MEBS’s unique technologies such as the global remote-maintenance service M’s BRIDGE, DOAS (Destination Oriented Allocation System, elevator coordination with mobile robots, Elevator Call System with Smartphone, and BMS (Building Management System). Elevator parts manufacturers MEBS receives numerous requests from customers with existing elevators In the overseas elevator market, there are many elevator parts manufacturers and specialized elevator maintenance companies that respond to diverse customer needs. With such a wide variety of choices available, MEBS receives numerous requests from customers with existing elevators made by other companies to provide them with higher-quality services by renewing their control systems using the control panels. MEBS’s newly developed control panel Normally, when combining a control panel with a traction machine from a different manufacturer, it is necessary to develop an individual control panel that matches the characteristics of the traction machine. However, by adopting MEBS’s newly developed control panel equipped with an autotuning function, there is no need to develop a dedicated control panel for each traction machine, and the latest control technology can be introduced while utilizing other companies’ traction machines. New autotuning function-equipped control panel The control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators As a result, performance can be improved while reducing costs and ensuring stable long-term operation. Until now, the control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators, but with this new autotuning function-equipped control panel, they can now offer control renewal for existing elevators made by other companies, which will allow us to meet an even wider variety of customer needs. Outlook MEBS, which is in charge of the building systems business, a key growth area for Mitsubishi Electric, is planning to expand and accelerate the global elevator maintenance and renewal business as a priority strategy. Through this menu, they are aiming to renew 1,000 elevators annually by 2030, mainly in North America and Europe.

Aldercote, the pioneering UK manufacturer of vehicle-mounted access platforms, has appointed a new sales executive to meet demand for the company’s innovative products, which are supplied to firms across the UK and Europe. Mark Tooley joins the team with almost a decade’s experience in the industry and will be working with current and prospective customers to help make them aware of Aldercote’s range of products and the expert engineering and diagnostic support services it offers. His previous role was with Access Hire, one of the largest hire companies in the sector. Aldercote’s commitment to innovation Mark said: “I’m looking forward to this new challenge in the industry I’ve gained a lifetime of experience in! I’m already enjoying engaging with customers and explaining how Aldercote’s commitment to engineering and innovation can help them find solutions for their platform needs." “I’ve had a really positive experience with the wider Aldercote team and it’s fantastic how we’re all working towards the company’s shared goals.” Aldercote’s VZ135e E-transit The firm launched its first platform designed especially for fully electric vehicles at the end of last year Established in Hull in 1999, Aldercote’s platforms are used by some of the UK and Ireland’s biggest utilities firms – including Openreach in the UK and Ireland’s electricity distribution network operator ESB – as well as local authorities, building maintenance providers and more. The company launched its first platform designed specifically for fully electric vehicles at the end of last year. The VZ135e E-transit is also Aldercote’s first to be built entirely without stabilizers – helping to increase vehicle payloads without compromising safety standards. Aldercote's new hires Marc Paish, Aldercote's managing director, said: “We are delighted to welcome Mark to the Aldercote team. His wealth of experience in the sector, and the knowledge he can share with us and our customers, is invaluable.” Two other new members have also recently joined the Aldercote team. Emily Boyd joins as customer relationship co-ordinator while Sam Dillon is the company’s newest service engineer. Both new hires are part of the company’s strategy ensuring gold-standard customer service.

On May 30, the first 100MWp tidal photovoltaics power station in China was connected to the grid with full capacity. This is the first time that China has complementary developed solar and tidal energy. The successful grid connection of this power station marks that China has made new achievements in the field of comprehensive utilization of marine energy. NR Electric provides a complete set of protection and monitoring equipment for the project, and implements the engineering integration of 110kV multi terminal differential (four terminal differential) line protection and 5MW/5MWh energy storage primary frequency modulation system. Frequency modulation system This project is the first PV power station in Zhejiang Province to synchronously constructe and install 5MW/5MWh energy storage system. Goose communication is used inside the energy storage system to realize the millisecond fast response The whole station has achieved a high level of automation. In conjunction with Zhejiang Electric Power Research Institute, the first photovoltaic power station fast frequency modulation pilot project was officially comissioned, which perfectly upgraded the coordination among energy storage, SVG and inverter. Goose communication is used inside the energy storage system to realize the millisecond fast response of primary frequency modulation with photovoltaics and energy storage. Power station reservoir area Zhejiang Wenling tidal PV Power Station is located in Jiangxia Tidal Power Station and Reservoir Area, Taizhou , Zhejiang. The total area of the reservoir area is about 1.33 km. The rated installed capacity is 100MWp. The project implements a new construction model of "new green energy tidal energy + solar energy", makes full use of the water surface of the power station reservoir area. After being connected to the grid, it is estimated that the annual average on-grid power generation will be about 106.87 million kWh, which will save 32,600 tons of standard coal every year.

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automation and ICS/SCADA security. Powered by the Intel® Xeon® 6 Processor, the ICS-P770 delivers exceptional compute performance, security acceleration, and high-speed connectivity for power grid applications. Designed to meet the most demanding requirements of modern digital substations, the ICS-P770 supports up to 512GB of DDR5 RDIMM memory and offers high-speed networking with four 2.5GbE RJ45, two GbE SFP, and two 25GbE/10GbE SFP/RJ45 interfaces. Redundant Storage Solutions The system provides multiple PCIe expansion slots, including 4 PCIe Gen5 slots, with support for HSR/PRP PCIe Card, ensuring seamless redundancy in the event of a network failure. Additionally, the industrial computer features four hot-swappable U.2 NVMe storage bays with RAID support, ensuring high-speed data logging and redundancy for critical energy applications. Strength Meets Security Designed to withstand harsh substation environments, the ICS-P770 features an IP30-rated rugged chassis with intelligent fan cooling and is certified for operation in extreme temperatures from -25°C to 55°C. Advanced security measures, including TPM 2.0 and Intel® QuickAssist Technology, ensure robust encryption, authentication, and secure remote access, making it an ideal choice for virtualization and SCADA security. Revolutionizing Substation Tech "Lanner Electronics' ICS-P770 is a game-changer for next-generation digital substations and virtual protection, automation, and control (vPAC). It offers unparalleled performance, availability, and reliability with its Intel® Xeon® 6 Processor (featuring 64 e-Cores), high-speed networking, network redundancy, and robust security features," said Dave Meng, Senior Director of Business Development for Power and Energy at Lanner. "This IEC 61850-3 certified server platform is designed to meet the most demanding requirements for substation virtualization.” Smart grid innovation Lanner invites industry professionals, system integrators, and energy leaders to Booth #5749 at DISTRIBUTECH 2025 for a firsthand look at how the ICS-P770 is transforming substation automation, real time analytics, and critical infrastructure protection.

Smartkem, which is seeking to change the world of electronics with a new class of transistor technology, announced that now, Friday, March 21, 2025, Chairman and CEO Ian Jenks, CFO Babara Keck, and Head of Communications Selena Kirkwood will ring the opening bell at the Nasdaq MarketSite in Times Square, NYC. Commercialization of microLED Jenks stated, "We are extremely excited and honored to ring the opening bell to increase awareness of our progress to enable the adoption and mass commercialization of microLED displays. We continue to advance our goal of commercializing our proprietary semiconductor materials, which enable flexible, transparent, and lightweight microLED displays." The Nasdaq opening bell ceremony will be broadcast live at 9:15 a.m. Eastern Time from the Nasdaq MarketSite Tower in New York City, New York.

Plasmalex, a pioneer in advanced coating solutions, proudly introduces PlasmaGuard X, the newest innovation in its PlasmaGuard® platform of high-performance barrier coatings. It is the result of years of dedicated research and development, reinforcing Plasmalex's commitment to sustainability and meeting the increasing environmental awareness among its clients. PlasmaGuard® coatings Launch of the new PlasmaGuard® X ultra-thin barrier coating builds on the same strengths PlasmaGuard® sets a new standard in high-performance ultra-thin splash proof and barrier coatings for the protection of a wide range of products such as medical devices, consumer electronics, PCBAs but also various non-woven or nanofiber materials. They are not only high-performing, but also environmentally responsible, being 100% PFAS-free. After the successful introduction of the PlasmaGuard® coatings in 2023, the launch of the new PlasmaGuard® X ultra-thin barrier coating builds on the same strengths and unique properties of the PlasmaGuard® product line, while offering even higher barrier and corrosion protection properties. PlasmaGuard® S splash-proof coating PlasmaGuard® S is a completely halogen-free nanocoating, typically applied at a thickness of 10 to 200 nanometers. With a water contact angle of more than 105°, it effectively minimizes water ingress. This coating is versatile; suitable for a wide array of materials, including electronics, plastics, textiles, (nano)membranes, and medical devices. PlasmaGuard® X barrier coating: NEW Remarkable strength ensures unparalleled protection for a wide range of applications PlasmaGuard® X is a fully PFAS-free dielectric barrier coating designed for applications requiring the highest level of protection, such as PCBAs, sensors, medical devices, and implants. This multilayer coating applied at a thickness below 1,5 µm outperforms conventional conformal coatings that are many times thicker. This remarkable strength ensures unparalleled protection for a wide range of applications. Cost-effective industrial coating solution PlasmaGuard® coatings are not only environmentally friendly but also a cost-effective solution, providing sustainable coating solutions without compromising performance or budget. Plasmalex has developed a full range of high-capacity industrial coating equipment and processes, both for batch as well as roll-to-roll applications, enabling a high-capacity throughput in production environments. Plasmalex invites industry professionals, clients, and stakeholders to explore the exceptional features and benefits of PlasmaGuard®.

Mitsubishi Electric Building Solutions Corporation (MEBS, Head Office: Chiyoda-Ku, Tokyo; President: Iwao Oda) announced the launch scheduled for 19 March of a new overseas control renewal menu for elevators made by other companies installed in existing buildings. By developing a new control panel with an auto-tuning function, MEBS will respond to the diverse needs of its overseas customers for the renewal of control systems for elevators, while spurring the expansion of its maintenance and renewal business. Main Features of Renewal Menu 1) Achieving control that maximizes ride comfort even with other companies' traction machines through auto-tuning It is possible to upgrade to the latest control system by utilizing an MEBS control panel together with a traction machine made by another company. The newly developed control panel equipped with an auto-tuning function estimates the characteristics of the other company’s traction machine and automatically derives the control parameters for the combination of the other company’s traction machine and the MEBS control panel. This eliminates the need to develop a dedicated control panel for the traction machine and improves ride comfort. 2) Improving safety and contributing to sustainability by promoting the renewal of existing elevators The renewal menu promotes the renewal of existing elevators to improve safety and convenience, and contributes to sustainability by reducing power consumption and waste emissions through the reuse of some of the equipment. The menu also reduces downtime by eliminating the need to replace all of the equipment. 3) Achieving improved convenience in response to diversifying building solution needs By adopting the renewal menu, it is possible to introduce integrated building solutions utilizing MEBS’s unique technologies such as the global remote-maintenance service M’s BRIDGE, DOAS (Destination Oriented Allocation System, elevator coordination with mobile robots, Elevator Call System with Smartphone, and BMS (Building Management System). Elevator parts manufacturers MEBS receives numerous requests from customers with existing elevators In the overseas elevator market, there are many elevator parts manufacturers and specialized elevator maintenance companies that respond to diverse customer needs. With such a wide variety of choices available, MEBS receives numerous requests from customers with existing elevators made by other companies to provide them with higher-quality services by renewing their control systems using the control panels. MEBS’s newly developed control panel Normally, when combining a control panel with a traction machine from a different manufacturer, it is necessary to develop an individual control panel that matches the characteristics of the traction machine. However, by adopting MEBS’s newly developed control panel equipped with an autotuning function, there is no need to develop a dedicated control panel for each traction machine, and the latest control technology can be introduced while utilizing other companies’ traction machines. New autotuning function-equipped control panel The control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators As a result, performance can be improved while reducing costs and ensuring stable long-term operation. Until now, the control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators, but with this new autotuning function-equipped control panel, they can now offer control renewal for existing elevators made by other companies, which will allow us to meet an even wider variety of customer needs. Outlook MEBS, which is in charge of the building systems business, a key growth area for Mitsubishi Electric, is planning to expand and accelerate the global elevator maintenance and renewal business as a priority strategy. Through this menu, they are aiming to renew 1,000 elevators annually by 2030, mainly in North America and Europe.

Aldercote, the pioneering UK manufacturer of vehicle-mounted access platforms, has appointed a new sales executive to meet demand for the company’s innovative products, which are supplied to firms across the UK and Europe. Mark Tooley joins the team with almost a decade’s experience in the industry and will be working with current and prospective customers to help make them aware of Aldercote’s range of products and the expert engineering and diagnostic support services it offers. His previous role was with Access Hire, one of the largest hire companies in the sector. Aldercote’s commitment to innovation Mark said: “I’m looking forward to this new challenge in the industry I’ve gained a lifetime of experience in! I’m already enjoying engaging with customers and explaining how Aldercote’s commitment to engineering and innovation can help them find solutions for their platform needs." “I’ve had a really positive experience with the wider Aldercote team and it’s fantastic how we’re all working towards the company’s shared goals.” Aldercote’s VZ135e E-transit The firm launched its first platform designed especially for fully electric vehicles at the end of last year Established in Hull in 1999, Aldercote’s platforms are used by some of the UK and Ireland’s biggest utilities firms – including Openreach in the UK and Ireland’s electricity distribution network operator ESB – as well as local authorities, building maintenance providers and more. The company launched its first platform designed specifically for fully electric vehicles at the end of last year. The VZ135e E-transit is also Aldercote’s first to be built entirely without stabilizers – helping to increase vehicle payloads without compromising safety standards. Aldercote's new hires Marc Paish, Aldercote's managing director, said: “We are delighted to welcome Mark to the Aldercote team. His wealth of experience in the sector, and the knowledge he can share with us and our customers, is invaluable.” Two other new members have also recently joined the Aldercote team. Emily Boyd joins as customer relationship co-ordinator while Sam Dillon is the company’s newest service engineer. Both new hires are part of the company’s strategy ensuring gold-standard customer service.

On May 30, the first 100MWp tidal photovoltaics power station in China was connected to the grid with full capacity. This is the first time that China has complementary developed solar and tidal energy. The successful grid connection of this power station marks that China has made new achievements in the field of comprehensive utilization of marine energy. NR Electric provides a complete set of protection and monitoring equipment for the project, and implements the engineering integration of 110kV multi terminal differential (four terminal differential) line protection and 5MW/5MWh energy storage primary frequency modulation system. Frequency modulation system This project is the first PV power station in Zhejiang Province to synchronously constructe and install 5MW/5MWh energy storage system. Goose communication is used inside the energy storage system to realize the millisecond fast response The whole station has achieved a high level of automation. In conjunction with Zhejiang Electric Power Research Institute, the first photovoltaic power station fast frequency modulation pilot project was officially comissioned, which perfectly upgraded the coordination among energy storage, SVG and inverter. Goose communication is used inside the energy storage system to realize the millisecond fast response of primary frequency modulation with photovoltaics and energy storage. Power station reservoir area Zhejiang Wenling tidal PV Power Station is located in Jiangxia Tidal Power Station and Reservoir Area, Taizhou , Zhejiang. The total area of the reservoir area is about 1.33 km. The rated installed capacity is 100MWp. The project implements a new construction model of "new green energy tidal energy + solar energy", makes full use of the water surface of the power station reservoir area. After being connected to the grid, it is estimated that the annual average on-grid power generation will be about 106.87 million kWh, which will save 32,600 tons of standard coal every year.

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automation and ICS/SCADA security. Powered by the Intel® Xeon® 6 Processor, the ICS-P770 delivers exceptional compute performance, security acceleration, and high-speed connectivity for power grid applications. Designed to meet the most demanding requirements of modern digital substations, the ICS-P770 supports up to 512GB of DDR5 RDIMM memory and offers high-speed networking with four 2.5GbE RJ45, two GbE SFP, and two 25GbE/10GbE SFP/RJ45 interfaces. Redundant Storage Solutions The system provides multiple PCIe expansion slots, including 4 PCIe Gen5 slots, with support for HSR/PRP PCIe Card, ensuring seamless redundancy in the event of a network failure. Additionally, the industrial computer features four hot-swappable U.2 NVMe storage bays with RAID support, ensuring high-speed data logging and redundancy for critical energy applications. Strength Meets Security Designed to withstand harsh substation environments, the ICS-P770 features an IP30-rated rugged chassis with intelligent fan cooling and is certified for operation in extreme temperatures from -25°C to 55°C. Advanced security measures, including TPM 2.0 and Intel® QuickAssist Technology, ensure robust encryption, authentication, and secure remote access, making it an ideal choice for virtualization and SCADA security. Revolutionizing Substation Tech "Lanner Electronics' ICS-P770 is a game-changer for next-generation digital substations and virtual protection, automation, and control (vPAC). It offers unparalleled performance, availability, and reliability with its Intel® Xeon® 6 Processor (featuring 64 e-Cores), high-speed networking, network redundancy, and robust security features," said Dave Meng, Senior Director of Business Development for Power and Energy at Lanner. "This IEC 61850-3 certified server platform is designed to meet the most demanding requirements for substation virtualization.” Smart grid innovation Lanner invites industry professionals, system integrators, and energy leaders to Booth #5749 at DISTRIBUTECH 2025 for a firsthand look at how the ICS-P770 is transforming substation automation, real time analytics, and critical infrastructure protection.

Smartkem, which is seeking to change the world of electronics with a new class of transistor technology, announced that now, Friday, March 21, 2025, Chairman and CEO Ian Jenks, CFO Babara Keck, and Head of Communications Selena Kirkwood will ring the opening bell at the Nasdaq MarketSite in Times Square, NYC. Commercialization of microLED Jenks stated, "We are extremely excited and honored to ring the opening bell to increase awareness of our progress to enable the adoption and mass commercialization of microLED displays. We continue to advance our goal of commercializing our proprietary semiconductor materials, which enable flexible, transparent, and lightweight microLED displays." The Nasdaq opening bell ceremony will be broadcast live at 9:15 a.m. Eastern Time from the Nasdaq MarketSite Tower in New York City, New York.

Plasmalex, a pioneer in advanced coating solutions, proudly introduces PlasmaGuard X, the newest innovation in its PlasmaGuard® platform of high-performance barrier coatings. It is the result of years of dedicated research and development, reinforcing Plasmalex's commitment to sustainability and meeting the increasing environmental awareness among its clients. PlasmaGuard® coatings Launch of the new PlasmaGuard® X ultra-thin barrier coating builds on the same strengths PlasmaGuard® sets a new standard in high-performance ultra-thin splash proof and barrier coatings for the protection of a wide range of products such as medical devices, consumer electronics, PCBAs but also various non-woven or nanofiber materials. They are not only high-performing, but also environmentally responsible, being 100% PFAS-free. After the successful introduction of the PlasmaGuard® coatings in 2023, the launch of the new PlasmaGuard® X ultra-thin barrier coating builds on the same strengths and unique properties of the PlasmaGuard® product line, while offering even higher barrier and corrosion protection properties. PlasmaGuard® S splash-proof coating PlasmaGuard® S is a completely halogen-free nanocoating, typically applied at a thickness of 10 to 200 nanometers. With a water contact angle of more than 105°, it effectively minimizes water ingress. This coating is versatile; suitable for a wide array of materials, including electronics, plastics, textiles, (nano)membranes, and medical devices. PlasmaGuard® X barrier coating: NEW Remarkable strength ensures unparalleled protection for a wide range of applications PlasmaGuard® X is a fully PFAS-free dielectric barrier coating designed for applications requiring the highest level of protection, such as PCBAs, sensors, medical devices, and implants. This multilayer coating applied at a thickness below 1,5 µm outperforms conventional conformal coatings that are many times thicker. This remarkable strength ensures unparalleled protection for a wide range of applications. Cost-effective industrial coating solution PlasmaGuard® coatings are not only environmentally friendly but also a cost-effective solution, providing sustainable coating solutions without compromising performance or budget. Plasmalex has developed a full range of high-capacity industrial coating equipment and processes, both for batch as well as roll-to-roll applications, enabling a high-capacity throughput in production environments. Plasmalex invites industry professionals, clients, and stakeholders to explore the exceptional features and benefits of PlasmaGuard®.

Expert Commentary

Fleet electrification provides opportunities to achieve climate goals while delivering social, financial, and environmental benefits to individuals, businesses, and communities, but the road to successful EV implementation is not without obstacles. Your EV fleets need to work — all the time under varying conditions — to ensure optimal uptime while maintaining energy efficiency. Consequently, electric vehicle service equipment (EVSE) can’t just be “tacked onto” your existing operation. Rather than a “new standalone addition,” it requires a thoughtful and forward-looking approach to seamlessly integrate into your overall facility. Ensuring the type of reliable power needed for an electrified fleet is critical. Luckily, there are a number of new and emerging solutions that promise to deliver clean and reliable local power generation. The Challenges The availability and reliability of the power needed to support electrified fleets is a primary roadblock for many commercial fleet operators. It’s important to look at where that power comes from, how much it will cost, and whether it will be available when needed. Projections indicate that the demand for electricity will surge by 50% during the next two decades Today’s energy landscape is complex. Projections indicate that the demand for electricity will surge by 50% during the next two decades, with no signs of slowing down. According to Grid Strategies, the U.S. electric grid is not prepared for this level of significant load growth. The sheer amount of power needed to keep trucks charged and running 24/7 can be substantial. This poses a key risk for reliability in EV infrastructures, particularly in mission-critical situations. In addition, most fleet operators have become accustomed to fairly predictable fuel costs, since many take advantage of long-term supply arrangements. By contrast, electricity grid costs can vary and result in unpredictable spikes. This adds an extra layer of complexity when it comes to the planning and timing of fleet charging. As a result, many fleet charging operations are turning to local power generation. Intelligent Microgrids, the Energy Insurance Microgrids are nothing new, with rural communities relying on them for decades. Increased affordability and shifting regulations are allowing for more of these microgrids to be powered by renewable energy methods. A common misconception is that microgrids can completely off-set power from the grid. In reality, they are designed to provide peak load shaving and system resiliency. Coupled with an EV infrastructure, microgrids can offer more flexible and reliable energy management. When compared to a traditional microgrid for a building system, microgrids for fleet electrification present new challenges. Most notably, microgrids for fleet electrification are not modeled on an existing load, but rather anticipated demand, which can make reliable load-based modeling more difficult. However, an "intelligent" microgrid uses control systems to manage, store, charge, and discharge energy across the system. Strategic energy management The system can buy power from the grid during low-cost periods while storing self-generated solar power These controls monitor supply and demand, track real-time electricity prices, and create efficient charging schedules, considering factors like Time of Use (TOU) and peak day rates. For example, when electric fleets plug in, demand may increase significantly overnight, making strategic energy management crucial. The system can buy power from the grid during low-cost periods while storing self-generated solar power for later use. When prices rise, it discharges stored energy, keeping costs stable. It can also operate independently, ensuring continuous power during outages and disruptions, improving efficiency, cost control, and reliability. Conversely, fleets often permit charging flexibility within defined boundaries, providing a unique dispatchable resource that can be tuned to fit the needs and energy resources of the customer. A New Category of Local Power Generation Linear generator technology is proving to be an innovative solution for EV infrastructures by providing flexible, resilient and cost-effective on-site base load power. Linear generator technology provides fuel-flexibility meaning they can directly run and switch among traditional fuels like natural gas or propane. Or, they can use low and zero-carbon fuels such as RNG, biogas, hydrogen, and ammonia. Its backup capabilities ensure power through hurricanes, sub-zero snowstorms, excessive heat, and other extreme conditions. Based on capex and operating costs, linear generators can provide a competitive levelized cost of ownership compared to grid power or other alternatives in certain regions. Net-zero goals These solutions allow for flexibility and integration of new fuels as they become available The technology can also be quickly deployed at scale, which is ideal for large fleet operators looking to quickly and cost-effectively deploy resilient EV charging infrastructure while reducing emissions and working toward net-zero goals. What’s more, linear generators deliver a more “future-proof” path. While the dominant sources of fuel for local power generation today is well understood, new and exciting fuels are on the horizon. These solutions allow for flexibility and integration of new fuels as they become available. All without having to replace or retrofit existing equipment. Experts Will Power the Future As companies look to integrate EVs into their operations, a well-thought-out plan for infrastructure is essential to ensure safety, reliability, and long-term success. The integration of onsite power systems will play a critical role in optimizing energy use, lowering costs, and maintaining system resilience. The good news is that energy management is becoming more flexible, ensuring that fleet electrification is not only sustainable but also cost-effective. To ensure a seamless transition and maximize the benefits of fleet electrification, many companies will be moving forward by working with experienced consultants and planners to create a future-proof infrastructure that meets both operational and environmental goals.

Power Beat

Electricians play a pivotal role in preventing electrical fires by following safe practices during installations, repairs, and inspections. At a minimum, electricians should ensure all electrical wiring and components are installed according to current building codes and manufacturers' specifications. This includes using the right size wires for the amperage load, using approved materials, and properly securing all connections. During electrical inspections, electricians should identify and address any potential fire hazards. Electricians can also advise homeowners on electrical safety measures they can take to prevent fires. These include safe appliance use, avoiding overloaded outlets, and the importance of smoke detectors and fire extinguishers. Maintenance of electrical systems Ground Fault Circuit Interrupters (GFCIs) can prevent possible fires. GFCI outlets have built-in protection to detect imbalances in electrical current and quickly shut off power to prevent shocks and potential fires, particularly in areas prone to moisture like kitchens and bathrooms. Regular maintenance of electrical systems is also crucial for fire prevention. Electricians can perform preventative maintenance checks to identify and address any developing issues before they become serious fire hazards. Fire departments responded to an average of 32,160 home fires involving electrical distribution Fire departments responded to an average of 32,160 home fires involving electrical distribution and lighting equipment each year in 2015–2019, according to the National Fire Protection Association (NFPA). Electrical fires cause scores of civilian deaths and hundreds of civilian injuries, as well as millions of dollars in property damage. Fire Hazards in the Home Some of the electrical components that present fire hazards in the home include faulty electrical outlets and switches, worn or damaged components, overloaded circuits, damaged or frayed cords, and misused extension cords and power strips. Improper use of light fixtures can also be a danger, and space heaters can be a fire hazard if they are placed too close to flammable materials or left unattended. Damaged or frayed cords can cause sparks and ignite nearby flammable materials As outlets and switches age, the wiring behind them can loosen and break, causing sparks and fire. Loose plugs can also overheat and ignite surrounding materials. Plugging too many appliances into a single outlet or using extension cords instead of proper wiring can overload a circuit, thus causing overheating and fires. Damaged or frayed cords can cause sparks and ignite nearby flammable materials. Cords that are kinked, pinched, or have exposed wires should be avoided and replaced immediately. Minimizing the Risk of Electrical Fires Here are some steps a homeowner can take to minimize the risk of fire from electrical systems: Upgrade the electrical system, especially if the home is older. If the electrical system has not been updated in a while, a qualified electrician can advise if it needs modernization. This could involve upgrading to breakers with better safety features such as Arc-Fault Circuit Interrupter (AFCI) and Ground Fault Circuit Interrupter (GFCI) technology. Schedule an electrical safety inspection. Having a qualified electrician periodically inspect a home's electrical system can identify potential problems before they escalate into fire hazards. Keep flammable materials away from electrical components, including curtains, furniture, and piles of paper. Sparks and overheating can easily ignite nearby flammables. Addressing Multiple Threats Effective communication is key for electricians to impress upon homeowners the seriousness of fire hazards. Avoid technical jargon and explain fire hazards in clear, concise language that homeowners can understand. Focus on the potential consequences, like damage to property or injury, to heighten awareness. Pictures can be worth a thousand words. Show homeowners examples of damaged wiring, overloaded outlets, or faulty installations that pose fire risks. This can be done through photos on a tablet or phone, or even carrying around small physical samples. Frame the conversation around safety for the homeowner and their family. Highlight how addressing these hazards can prevent potential fires and ensure a safe living environment. Provide a written report after the inspection or repair. This report should detail the identified hazards, the corrective actions taken, and any recommendations for future maintenance or upgrades. By combining clear communication, visual aids, and a focus on safety, electricians can effectively convey the importance of addressing fire hazards to homeowners and empower them to make informed decisions about their electrical systems.

Rising material prices and inflation, in general, are likely to continue to plague electricians and others in the trade service businesses, according to a new survey conducted by the business management software platform Simpro. In the survey, 20% of electrical respondents say they are more likely to face rising material prices this year, while 20% of owners, CEOs, and business managers in the broader category of trade service businesses are more likely to face inflation concerns. ongoing economic uncertainty Another big concern across all trade service businesses is staff retention. Even higher percentages of survey respondents expect continuing challenges presented by the labor market: 73% anticipate hiring to be more challenging in 2023 than last year because of a lack of skilled workers (cited by 51% of respondents) and ongoing economic uncertainty (cited by 50%). The survey, conducted in January 2023, also highlighted changes trade service companies saw in the market last year compared to 2021. Customer acquisition Customer acquisition was more challenging in 2022, according to 66% of survey respondents In a service-based industry, customer satisfaction is a high priority: 95% of trade professionals noted that customer experience is paramount, and 73% have adopted technology tools specifically designed to enhance the customer experience. Customer acquisition was more challenging in 2022, according to 66% of survey respondents, while customer retention was more challenging for 60% of respondents. Hiring was also more difficult than in 2021, according to 76% of the survey respondents. Simpro’s smart technology solutions In the survey, Simpro seeks to highlight the ways technological innovations can shape the future of trade services businesses and their customers. Simpro’s total business management software platform for commercial trade service businesses performs functions such as job quoting, scheduling, inventory tracking, invoicing, and others. Simpro’s smart technology solutions and expert long-term support help businesses build, repair and power their future with control over operations. “Voice of the Trades” survey Trade professionals are estimated to spend more than 18 hours a week on tasks such as scheduling In the “Voice of the Trades” survey, 72% of trade professionals (including HVAC, security, plumbers, contractors, electricians, and others) believe that new software and technology must be adopted to remain competitive. Also, 60% feel that administrative burdens have a negative impact on their ability to service customers. Trade professionals, including electricians, estimate they spend more than 18 hours a week on tasks such as scheduling, inventory, invoicing and overall workflow management. The report reveals why it is so hard to find a contractor or service technician right now: 49% of respondents share a belief that time on admin has directly contributed to that customer frustration. Clear roadmap for operational efficiency “The Voice of the Trades findings confirm the need for trade businesses worldwide to implement technology solutions to lessen the burden of business management in any economy,” said Gary Specter, CEO of Simpro. “This research provides a clear roadmap for improving operational efficiency so trade organizations can better serve their customers.” The report gleaned feedback from 840 respondents who are trade industry professionals, with a geographic pool that includes the U.S., U.K., Australia, New Zealand, and Canada. Founded in 2002 by an electrical contractor and headquartered in Brisbane, Australia, Simpro supports more than 8,000 businesses and 200,000 users worldwide in the electrical, plumbing, HVAC, security and fire protection industries with 700-plus employees in six offices around the world.

The electrical industry is expected to have a labor shortage of about 60,000 workers by 2026. A labor shortage in the electrical trade is not inevitable, but it is likely to continue if the industry does not take steps to address the issue. Like other skilled trades, the electrical industry is facing challenges that could contribute to a labor shortage, including an aging workforce, a lack of interest among younger generations, and competition from other industries. However, there are strategies the industry can implement to address these challenges and attract a new generation of workers. These strategies include increasing awareness of the benefits and opportunities of skilled trades, investing in training and education programs, improving working conditions and compensation, embracing technology, promoting diversity and inclusivity, and collaborating among industry, education, and government. Improving working conditions Factors in the current labor shortage in the electrical industry include: Aging workforce: Many workers in the electrical industry are nearing retirement age, and there are not enough younger workers to replace them. This has led to a shortage of skilled workers with many years of experience in the industry. Lack of interest in the trades: There has been a decline in the number of young people pursuing careers in the skilled trades, including electrical work. This is due in part to a focus on four-year college degrees as the preferred career path, as well as a lack of awareness of the benefits and opportunities of skilled trades. Competition from other industries: The electrical industry is competing with other industries, such as construction and manufacturing, for skilled workers. Training and education: Training and education are critical for developing the skills and knowledge necessary for electrical work. However, there is a shortage of qualified trainers and educators. Increasing demand: The demand for electrical services is increasing, particularly in areas such as renewable energy and smart grid technology. Attracting and retaining workers To attract and retain workers, the electrical industry must offer competitive wages and benefits One strategy to address the labor shortage is to increase awareness of skilled trades and to promote the benefits of a career in the electrical industry through outreach programs in schools, career fairs, and other events. Providing access to quality training and education programs that develop the skills and knowledge necessary for electrical work is crucial for attracting and retaining workers. This can be done through apprenticeship programs, vocational schools, and community colleges. To attract and retain workers, the electrical industry must offer competitive wages and benefits, as well as a safe and supportive work environment. This includes offering training and development opportunities, flexible schedules, and opportunities for advancement. Inclusive work environment The electrical industry is changing rapidly, and workers must be equipped with the latest technology and tools to stay competitive. Providing workers with training and access to the latest technology can help attract and retain workers. The electrical industry should actively promote diversity and inclusivity to attract a wider pool of workers. This includes efforts to recruit workers from underrepresented groups and create a welcoming and inclusive work environment. The electrical industry is changing rapidly, and workers must be equipped with the latest technology Companies in the electrical industry are addressing the labor shortage problem by investing in workforce development programs and initiatives. For example, Schneider Electric has developed a comprehensive workforce development program called the Schneider Electric Energy and Automation Training (SEAT) program. The SEAT program provides training and certification for employees, customers, and partners in areas such as energy management, automation, and digital transformation. Developing training programs Siemens has developed several initiatives to address the labor shortage in the electrical industry. These initiatives include apprenticeship programs, vocational training programs, and partnerships with educational institutions to develop training programs. Graybar, a distributor of electrical products and solutions, has developed a workforce development program called Graybar University to provide training and education for employees, customers, and partners in areas such as lighting, automation, and safety. Joint apprenticeship training program Collaboration among industry, education, and government is crucial for developing solutions The International Brotherhood of Electrical Workers (IBEW) and the National Electrical Contractors Association (NECA) have developed a joint apprenticeship training program that provides training and education for individuals looking to enter the electrical industry. The program provides on-the-job training and education in areas such as electrical theory, safety, and installation. Collaboration among industry, education, and government is crucial for developing solutions to the labor shortage in the electrical industry. This includes partnerships between industry and education institutions to provide training and education programs, as well as government initiatives to support workforce development in the skilled trades.

Case studies

Jenkins sold a Jenkins Motor Test System to Oman, where temperatures can exceed 120ºF. While Jenkins Motor Test Systems are built tough and for industrial environments, this specific location required customizations to be the most effective in an extremely hot environment. Locations near large bodies of water or tropical environments can also cause problems as the humidity in the air will cause the copper wiring in the transformer to oxidize over time. Although Jenkins designs its equipment to operate for long periods, some applications for customer environments require specific customization. The Solution Jenkins engineers and winders worked together to develop a custom solution for this harsh climate, particularly paying close attention to temperature and water resistance. To customize the transformer for this environment, the Jenkins team made the following modifications: Doubling the spacing between winding layers to increase airflow. Encasing the transformer first in a high tolerance epoxy varnish, and then in a polyester over-dip that prevents the application from rust, dust, and harmful materials. Utilizing expanded metal at the base of the MTS enclosure, allows heat to escape, reducing the internal temperature. Installing temperature-sensitive cooling fans (set to 100ºF) atop the enclosure to prevent overheating. The Results Jenkins technicians checked insulation for 10,000 volts (resistance to ground), checked each voltage leg, and high voltage potential to ground, and ensured the taps were in the correct place. Voltage was confirmed to operate up to 20% above normal operation, ensuring maximum efficiency and longevity of the transformer. These modifications have resulted in prolonged use of the Jenkins Motor Test System in harsh environments and ultimately customer satisfaction.

Fluence Energy, Inc., a global provider of energy storage products, services, and optimization software for renewables and storage, announces that the company has been selected by Origin Energy Limited (Origin) to deliver a 300 MW / 650 MWh battery at the Mortlake Power Station in southwest Victoria. The project will use Fluence’s Gridstack™ energy storage product with a 15-year service agreement contributing to Origin’s strategy to accelerate renewable energy and energy storage in its portfolio. The system will also utilize Fluence’s AI-powered asset performance management (APM) software, Nispera™, to optimize the battery’s operational performance. Energy storage projects The system will capture excess power during periods of high renewable generation “We are honored to be selected by Origin to deliver this grid-forming battery-based energy storage system and deploy our ecosystem of solutions,” said Fluence President and Chief Executive Officer, Julian Nebreda. Julian Nebreda adds, “Australia is an important market for Fluence. Our local team is now delivering over 1 GW energy storage projects within Australia to enhance grid stability and enable the country’s clean energy transition.” Energy storage system to be commissioned in late 2026 The site preparation and civil works of the Mortlake Battery are expected to commence following a period of detailed design and procurement activity. The energy storage system is anticipated to be commissioned in late 2026. Located in Victoria’s South West Renewable Energy Zone, this energy storage system will provide system strength to the grid. The system will capture excess power during periods of high renewable generation and discharge to meet peak demand.

Mota-Engil, a multi-national with activities focused on the construction and management of infrastructures, responsible for the construction of the Canoas wastewater lifting station, selected WEG as the provider of a large package of electrical solutions for an important initiative to decontaminate the waters of the Bogotá River, in Colombia. Sustainable development When the project is completed, the pumping station will receive the wastewater from approximately 70% of the city, corresponding to the Fucha, Tintal, and Tunjuelo river basins, and the wastewater from the Municipality of Soacha, to be later pumped to the future Canoas Wastewater Treatment Plant, which will be one of the largest in Latin America. This great milestone will make it possible to return quality water to the Bogotá River and guarantee the sustainable development of the country. Safe distribution of energy Seventeen medium voltage switchgears were also supplied in addition to low voltage load centers One of the great challenges of this project is to guarantee the safe distribution of energy to the electrical systems and motors. For this, WEG has supplied a complete 115 kV substation that includes two 30 MVA/115/13.2 kV transformers, adding more efficiency and reliability to the plant. 17 medium voltage switchgears were also supplied in addition to low voltage load centers. For this project, WEG will also be supplying six three-phase induction motors and six medium voltage variable frequency drives. Each 4,300 kW motor, vertically mounted, will be coupled to its respective pump and will be responsible for pumping 6.4 cubic meters of wastewater per second to 51.6 meters height from the well, one of the most critical processes in the plant. Improvement of the quality of life This demonstrates the company's ability to develop integrated solutions that meet the most diverse applications. With participation in other important projects in the water and wastewater segment, in various processes such as potable water treatment plants, wastewater treatment, and distribution systems, WEG reinforces its experience in this segment by being selected for this important project, thus contributing to the improvement of the quality of life of the population and the environment.

Zermatt is a truly unique destination nestled in the Swiss Alps. The town is primarily renowned for its iconic Matterhorn Mountain, which stands at 4,478 meters and is one of the highest and most recognizable peaks in the Alps. Zermatt’s landscape includes 38 peaks over 4,000 meters. With around 2.5 million overnight stays recorded in 2023, Zermatt is one of the most popular tourist destinations in Switzerland. However, due to the town’s remote location and rugged terrain, Zermatt faces specific challenges. These include the need for reliable and sustainable infrastructure and the management of natural risks, such as avalanches and extreme weather events, which can disrupt infrastructure and pose safety concerns. These factors, combined with the altitude difference, oxygen-deficient air, and steep terrain, underscore the need for innovative solutions. For decades, together with its innovative customers, Siemens has been developing technological solutions to meet these challenges. Evaluation of energy flows The hut operates mainly autonomously and is largely self-sufficient in its energy needs The Monte Rosa Hut, located 2,883 meters above sea level, is one of the most iconic mountain huts in Switzerland. The high-tech hut has been equipped with Siemens building technology since its reopening in 2010. In 2021, 8.6 tons of lead batteries were replaced by 2.7 tons of lithium batteries. Continuous online evaluation of energy flows indicated the need for a new solution as the existing lead batteries would soon reach the end of their lifespan. The hut operates mainly autonomously and is largely self-sufficient in its energy needs. With the building management system Desigo CC, as the comprehensive on-site solution to manage all the systems, such as HVAC, Shading, Lighting, Power, Fire Safety, and Security, the operator can quickly review the key equipment values, check key room KPIs, and troubleshoot any potential problems. Troubleshooting potential problems In 2024, the open and flexible IoT platform “Building X” from Siemens was deployed. Building X is the scalable digital building platform to digitalize, manage, and optimize building operations, allowing for an enhanced user experience, increased performance, and improved sustainability. The Matterhorn summer paradise offers bike trails, adventurous kickbike and dirt scooter descents Zermatt Bergbahnen AG is Switzerland’s largest cable car company. The cable car station ‘Matterhorn glacier paradise’ is Europe’s highest cable car station at 3,883 m above sea level. It offers year-round snow experiences and stunning views of 38 peaks over 4,000 m. The Matterhorn summer paradise offers bike trails, adventurous kickbike and dirt scooter descents, and 400 km hiking trails. In the winter, the company offers, together with Cervinia/Valtournenche, 54 lifts and a total of 360 km of slopes. Rapidly changing weather Infrastructure in mountainous and challenging terrain demands high standards due to factors such as altitude, low oxygen levels, and rapidly changing weather. Siemens and Zermatt Bergbahnen share a long-standing and successful partnership in areas such as low-voltage power supply and state-of-the-art control solutions, which has been expanded with the completion of the Matterhorn Alpine Crossing and the connection from Matterhorn Glacier Paradise to Testa Grigia in Italy. Siemens solutions provide complete transparency and traceability of the system, thereby ensuring a seamless energy management overview of the entire infrastructure. This system ensures that all the energy values can be managed directly on the control units and displayed graphically on a state-of-the-art display/HMI or SCADA. Data from different subsystems provided by a wide range of manufacturers can be easily integrated into the overall Siemens system via standardized interfaces. Remote management of critical systems The Gornergrat Railway (GGB) and Matterhorn Gotthard Railway (MGB) are part of the BVZ Group The Gornergrat Railway (GGB) and Matterhorn Gotthard Railway (MGB) are part of the BVZ Group, which includes 10 subsidiaries. The BVZ Group provides public transport and tourism services in the cantons of Valais, Uri, and Grisons. The GGB adopted the first cloud-based operational model in 2017, which was facilitated by Siemens Mobility. It ensures seamless and reliable operation. This innovative approach eliminates the need for on-site server infrastructure and allows for the remote management of critical systems. The integrated control and information system, known as “Iltis”, enhances operational efficiency and safety. This system enables remote control of signaling, monitoring of operations, and management of passenger information systems. Streamlining depot operations Another world premiere in 2023: The first mobile depot control system in the cloud, the Controlguide® TrackOps Depot, for the Matterhorn Gotthard Bahn. Controlguide® TrackOps Depot is an innovative depot control solution, enabling the local management of shunting activities and streamlining depot operations. Utilizing cloud-based technologies, Siemens provided flexible and scalable depot control solutions to ensure the efficient management of railway operations. Tablet-based control interfaces were introduced for depot operations, thereby enabling the simplified and efficient management of shunting activities directly from the field.

RO Capital Partners (“ROCP”), the RO Group’s venture capital arm, announces that its portfolio company, measurable.energy, has installed its smart power sockets in the office of PKF Francis Clark in Bristol. PKF Francis Clark is an award-winning firm of chartered accountants and business advisers. measurable.energy is a UK tech company that designs and manufactures smart, machine-learning-enabled power sockets that will reduce the energy costs of PKF Francis Clark’s Bristol office by more than 20%. PKF Francis Clark is located at 90 Victoria Street in that city, an office building comprising 24,377 sq. ft. of high-quality office accommodation across four storeys. Small Power energy use Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type measurable.energy’s solution eliminates ‘Small Power’ waste, which is energy not required by devices that are plugged in or directly wired; such as printers, AV equipment, chilled and hot water taps, monitors, and heaters, and which are often left fully on or in standby mode overnight. Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type of ‘Small Power’ energy use. Edward Rowlandson, Group Managing Director, the RO, said: "We are very pleased to have installed measurable.energy’s technology in our flagship Bristol property for a key tenant, PKF Francis Clark. We acquired 90 Victoria Street in Bristol in April 2023, and ROCP’s investment into Reading-based measurable.energy was also made early in 2023." PKF Francis Clark’s values Rowlandson added: “That investment was driven by the need to reduce energy, and we are delighted that PKF Francis Clark’s values align with our own, and that of measurable.energy. We look forward to seeing their simple solution for office occupiers who are under pressure to take action, cut energy costs, and reduce emissions installed in more properties around the country, as the business looks to scale.” CEO and Co-Founder of measurable.energy, Dan Williams said: “My electricity-saving message to companies is to not be fooled by the small size of certain devices. A very high percentage of an office occupier’s electricity bill hides in the shadows, among small gadgets and forgotten chargers." Power usage patterns Williams added:"This silent power drain adds up faster than tenants think, and without ever realizing it. Powered by machine learning, our plug sockets will automatically identify and eliminate ‘Small Power’ waste for PKF Francis Clark, turning every appliance in their Bristol office into a cost-saving superhero.” Jim Solomon, Regional Facilities Manager at PKF Francis Clark concluded: “Since deploying measurable. energy's AI-powered sockets, we have not only reduced our office's energy consumption of the devices using the sockets by 38%, but have also gained invaluable insights into our power usage patterns. This technology has been instrumental in our efforts to operate more sustainably and efficiently.”

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.

Jenkins sold a Jenkins Motor Test System to Oman, where temperatures can exceed 120ºF. While Jenkins Motor Test Systems are built tough and for industrial environments, this specific location required customizations to be the most effective in an extremely hot environment. Locations near large bodies of water or tropical environments can also cause problems as the humidity in the air will cause the copper wiring in the transformer to oxidize over time. Although Jenkins designs its equipment to operate for long periods, some applications for customer environments require specific customization. The Solution Jenkins engineers and winders worked together to develop a custom solution for this harsh climate, particularly paying close attention to temperature and water resistance. To customize the transformer for this environment, the Jenkins team made the following modifications: Doubling the spacing between winding layers to increase airflow. Encasing the transformer first in a high tolerance epoxy varnish, and then in a polyester over-dip that prevents the application from rust, dust, and harmful materials. Utilizing expanded metal at the base of the MTS enclosure, allows heat to escape, reducing the internal temperature. Installing temperature-sensitive cooling fans (set to 100ºF) atop the enclosure to prevent overheating. The Results Jenkins technicians checked insulation for 10,000 volts (resistance to ground), checked each voltage leg, and high voltage potential to ground, and ensured the taps were in the correct place. Voltage was confirmed to operate up to 20% above normal operation, ensuring maximum efficiency and longevity of the transformer. These modifications have resulted in prolonged use of the Jenkins Motor Test System in harsh environments and ultimately customer satisfaction.

Fluence Energy, Inc., a global provider of energy storage products, services, and optimization software for renewables and storage, announces that the company has been selected by Origin Energy Limited (Origin) to deliver a 300 MW / 650 MWh battery at the Mortlake Power Station in southwest Victoria. The project will use Fluence’s Gridstack™ energy storage product with a 15-year service agreement contributing to Origin’s strategy to accelerate renewable energy and energy storage in its portfolio. The system will also utilize Fluence’s AI-powered asset performance management (APM) software, Nispera™, to optimize the battery’s operational performance. Energy storage projects The system will capture excess power during periods of high renewable generation “We are honored to be selected by Origin to deliver this grid-forming battery-based energy storage system and deploy our ecosystem of solutions,” said Fluence President and Chief Executive Officer, Julian Nebreda. Julian Nebreda adds, “Australia is an important market for Fluence. Our local team is now delivering over 1 GW energy storage projects within Australia to enhance grid stability and enable the country’s clean energy transition.” Energy storage system to be commissioned in late 2026 The site preparation and civil works of the Mortlake Battery are expected to commence following a period of detailed design and procurement activity. The energy storage system is anticipated to be commissioned in late 2026. Located in Victoria’s South West Renewable Energy Zone, this energy storage system will provide system strength to the grid. The system will capture excess power during periods of high renewable generation and discharge to meet peak demand.

Mota-Engil, a multi-national with activities focused on the construction and management of infrastructures, responsible for the construction of the Canoas wastewater lifting station, selected WEG as the provider of a large package of electrical solutions for an important initiative to decontaminate the waters of the Bogotá River, in Colombia. Sustainable development When the project is completed, the pumping station will receive the wastewater from approximately 70% of the city, corresponding to the Fucha, Tintal, and Tunjuelo river basins, and the wastewater from the Municipality of Soacha, to be later pumped to the future Canoas Wastewater Treatment Plant, which will be one of the largest in Latin America. This great milestone will make it possible to return quality water to the Bogotá River and guarantee the sustainable development of the country. Safe distribution of energy Seventeen medium voltage switchgears were also supplied in addition to low voltage load centers One of the great challenges of this project is to guarantee the safe distribution of energy to the electrical systems and motors. For this, WEG has supplied a complete 115 kV substation that includes two 30 MVA/115/13.2 kV transformers, adding more efficiency and reliability to the plant. 17 medium voltage switchgears were also supplied in addition to low voltage load centers. For this project, WEG will also be supplying six three-phase induction motors and six medium voltage variable frequency drives. Each 4,300 kW motor, vertically mounted, will be coupled to its respective pump and will be responsible for pumping 6.4 cubic meters of wastewater per second to 51.6 meters height from the well, one of the most critical processes in the plant. Improvement of the quality of life This demonstrates the company's ability to develop integrated solutions that meet the most diverse applications. With participation in other important projects in the water and wastewater segment, in various processes such as potable water treatment plants, wastewater treatment, and distribution systems, WEG reinforces its experience in this segment by being selected for this important project, thus contributing to the improvement of the quality of life of the population and the environment.