Energy Reduction

On June 7, 2021, the generator terminal subsynchronous damping control (GTSDC) system of Datang Xilinhaote (Xilinhot) power plant completed the oscillation suppression test and put into operation successfully. NR worked as the total solution provider for this project. The successful operation of the system enhances the damping performance of the complex resonance between the generator and the grid, and can effectively solve the torsional vibration problem of the turbine generator shaft system u...

On January 20, 2022, the first converter valve of the China Great Bay Area DC back-to-back project was successfully put into operation for the first time, marking an important step forward for the interconnection of the core areas of the Eastern and Western Pearl River Delta of the Guangdong power grid. The converter valves were supplied by NR. Unit 1 on the East side of Guangzhou took the lead in entering the system commissioning stage among the four units of the whole project, creating a new...

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U...

Tolomatic Inc., an industry pioneer in innovative linear motion systems, will be showcasing its latest servo linear actuators at Automate 2025. Featuring an integrated servo motor, Tolomatic servo linear actuators are ideal for applications where dynamic movement, precise positioning and force repeatability are a priority. Tolomatic products Tolomatic products include the IMA and IMA-S linear servo actuators. These actuators feature integrated servo motors to save space and are available in b...

Smartkem, which is seeking to change the world of electronics with a new class of transistor technology, announced that now, Friday, March 21, 2025, Chairman and CEO Ian Jenks, CFO Babara Keck, and Head of Communications Selena Kirkwood will ring the opening bell at the Nasdaq MarketSite in Times Square, NYC. Commercialization of microLED Jenks stated, "We are extremely excited and honored to ring the opening bell to increase awareness of our progress to enable the adoption and mass commercial...

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, unveiled its broad spectrum of next-generation power and liquid cooling solutions at NVIDIA GTC 2025. These solutions are designed to bolster the performance and energy conservation in NVIDIA-enabled AI and HPC data centers, including the newly launched Power Capacitance Shelves and in-row 1.5MW liquid-to-liquid Coolant Distribution Units (CDU). NVIDIA Omniverse™ platform Delta’s AI-based Smart...

News

Plasmalex, a pioneer in advanced coating solutions, proudly introduces PlasmaGuard X, the newest innovation in its PlasmaGuard® platform of high-performance barrier coatings. It is the result of years of dedicated research and development, reinforcing Plasmalex's commitment to sustainability and meeting the increasing environmental awareness among its clients. PlasmaGuard® coatings Launch of the new PlasmaGuard® X ultra-thin barrier coating builds on the same strengths PlasmaGuard® sets a new standard in high-performance ultra-thin splash proof and barrier coatings for the protection of a wide range of products such as medical devices, consumer electronics, PCBAs but also various non-woven or nanofiber materials. They are not only high-performing, but also environmentally responsible, being 100% PFAS-free. After the successful introduction of the PlasmaGuard® coatings in 2023, the launch of the new PlasmaGuard® X ultra-thin barrier coating builds on the same strengths and unique properties of the PlasmaGuard® product line, while offering even higher barrier and corrosion protection properties. PlasmaGuard® S splash-proof coating PlasmaGuard® S is a completely halogen-free nanocoating, typically applied at a thickness of 10 to 200 nanometers. With a water contact angle of more than 105°, it effectively minimizes water ingress. This coating is versatile; suitable for a wide array of materials, including electronics, plastics, textiles, (nano)membranes, and medical devices. PlasmaGuard® X barrier coating: NEW Remarkable strength ensures unparalleled protection for a wide range of applications PlasmaGuard® X is a fully PFAS-free dielectric barrier coating designed for applications requiring the highest level of protection, such as PCBAs, sensors, medical devices, and implants. This multilayer coating applied at a thickness below 1,5 µm outperforms conventional conformal coatings that are many times thicker. This remarkable strength ensures unparalleled protection for a wide range of applications. Cost-effective industrial coating solution PlasmaGuard® coatings are not only environmentally friendly but also a cost-effective solution, providing sustainable coating solutions without compromising performance or budget. Plasmalex has developed a full range of high-capacity industrial coating equipment and processes, both for batch as well as roll-to-roll applications, enabling a high-capacity throughput in production environments. Plasmalex invites industry professionals, clients, and stakeholders to explore the exceptional features and benefits of PlasmaGuard®.

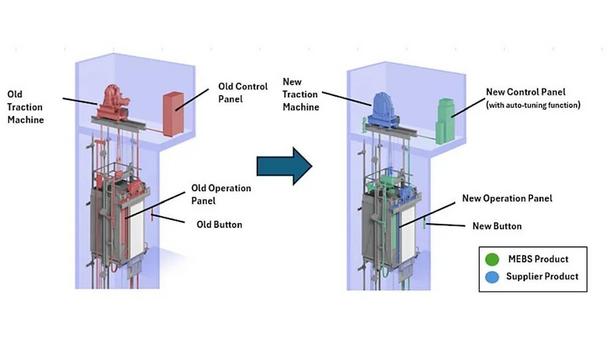

Mitsubishi Electric Building Solutions Corporation (MEBS, Head Office: Chiyoda-Ku, Tokyo; President: Iwao Oda) announced the launch scheduled for 19 March of a new overseas control renewal menu for elevators made by other companies installed in existing buildings. By developing a new control panel with an auto-tuning function, MEBS will respond to the diverse needs of its overseas customers for the renewal of control systems for elevators, while spurring the expansion of its maintenance and renewal business. Main Features of Renewal Menu 1) Achieving control that maximizes ride comfort even with other companies' traction machines through auto-tuning It is possible to upgrade to the latest control system by utilizing an MEBS control panel together with a traction machine made by another company. The newly developed control panel equipped with an auto-tuning function estimates the characteristics of the other company’s traction machine and automatically derives the control parameters for the combination of the other company’s traction machine and the MEBS control panel. This eliminates the need to develop a dedicated control panel for the traction machine and improves ride comfort. 2) Improving safety and contributing to sustainability by promoting the renewal of existing elevators The renewal menu promotes the renewal of existing elevators to improve safety and convenience, and contributes to sustainability by reducing power consumption and waste emissions through the reuse of some of the equipment. The menu also reduces downtime by eliminating the need to replace all of the equipment. 3) Achieving improved convenience in response to diversifying building solution needs By adopting the renewal menu, it is possible to introduce integrated building solutions utilizing MEBS’s unique technologies such as the global remote-maintenance service M’s BRIDGE, DOAS (Destination Oriented Allocation System, elevator coordination with mobile robots, Elevator Call System with Smartphone, and BMS (Building Management System). Elevator parts manufacturers MEBS receives numerous requests from customers with existing elevators In the overseas elevator market, there are many elevator parts manufacturers and specialized elevator maintenance companies that respond to diverse customer needs. With such a wide variety of choices available, MEBS receives numerous requests from customers with existing elevators made by other companies to provide them with higher-quality services by renewing their control systems using the control panels. MEBS’s newly developed control panel Normally, when combining a control panel with a traction machine from a different manufacturer, it is necessary to develop an individual control panel that matches the characteristics of the traction machine. However, by adopting MEBS’s newly developed control panel equipped with an autotuning function, there is no need to develop a dedicated control panel for each traction machine, and the latest control technology can be introduced while utilizing other companies’ traction machines. New autotuning function-equipped control panel The control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators As a result, performance can be improved while reducing costs and ensuring stable long-term operation. Until now, the control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators, but with this new autotuning function-equipped control panel, they can now offer control renewal for existing elevators made by other companies, which will allow us to meet an even wider variety of customer needs. Outlook MEBS, which is in charge of the building systems business, a key growth area for Mitsubishi Electric, is planning to expand and accelerate the global elevator maintenance and renewal business as a priority strategy. Through this menu, they are aiming to renew 1,000 elevators annually by 2030, mainly in North America and Europe.

Aldercote, the pioneering UK manufacturer of vehicle-mounted access platforms, has appointed a new sales executive to meet demand for the company’s innovative products, which are supplied to firms across the UK and Europe. Mark Tooley joins the team with almost a decade’s experience in the industry and will be working with current and prospective customers to help make them aware of Aldercote’s range of products and the expert engineering and diagnostic support services it offers. His previous role was with Access Hire, one of the largest hire companies in the sector. Aldercote’s commitment to innovation Mark said: “I’m looking forward to this new challenge in the industry I’ve gained a lifetime of experience in! I’m already enjoying engaging with customers and explaining how Aldercote’s commitment to engineering and innovation can help them find solutions for their platform needs." “I’ve had a really positive experience with the wider Aldercote team and it’s fantastic how we’re all working towards the company’s shared goals.” Aldercote’s VZ135e E-transit The firm launched its first platform designed especially for fully electric vehicles at the end of last year Established in Hull in 1999, Aldercote’s platforms are used by some of the UK and Ireland’s biggest utilities firms – including Openreach in the UK and Ireland’s electricity distribution network operator ESB – as well as local authorities, building maintenance providers and more. The company launched its first platform designed specifically for fully electric vehicles at the end of last year. The VZ135e E-transit is also Aldercote’s first to be built entirely without stabilizers – helping to increase vehicle payloads without compromising safety standards. Aldercote's new hires Marc Paish, Aldercote's managing director, said: “We are delighted to welcome Mark to the Aldercote team. His wealth of experience in the sector, and the knowledge he can share with us and our customers, is invaluable.” Two other new members have also recently joined the Aldercote team. Emily Boyd joins as customer relationship co-ordinator while Sam Dillon is the company’s newest service engineer. Both new hires are part of the company’s strategy ensuring gold-standard customer service.

Rethinking filtration: with BECO® Helix depth filter cartridges, Eaton's Filtration Division introduces a completely new approach to liquid filtration. These innovative depth filter cartridges provide a double depth filtration effect, significantly higher particle-holding capacity, and a longer service-life compared to other pleated depth filter cartridges. This performance is made possible by the unique helix wrapping of the pleated polypropylene (PP) fleece layers. BECO Helix depth filter cartridges The fine fleece layers provide reliable separation in particle, clarifying, and fine filtration The innovative structure and the graduated, thin fleece layers from coarse to fine, maximize the filter surface area and allow optimal flow with low pressure differentials. The funnel effect and high mechanical stability of the graduated fleece layers make BECO Helix depth filter cartridges excellent for backwashing. The fine fleece layers provide reliable separation in particle, clarifying, and fine filtration, while also protecting downstream membrane filter cartridges. Variety of different applications and filter housings Available in various lengths, with all common adapter designs and gasket materials, the BECO Helix depth filter cartridges ensure safe use across a variety of different applications and filter housings. The depth filter cartridges have a filter area of 0.7 square meters per 10-inch element, they are available with retention rates from 0.6 to 10.0 µm, and are available immediately. Regeneration and sterilization instructions "The BECO Helix depth filter cartridge with a retention rate of 0.6 µm was specifically designed for bottling processes in the beverage industry. It protects downstream membrane filters from clogging substances and significantly extends their service-life, provided the regeneration and sterilization instructions are properly followed," explains Elke Brandscheid, Team Leader Technical Service & Product Manager Filter Cartridges of Eaton's Filtration Division. The CIP and SIP capability (Clean-in-Place and Sterilize-in-Place) of the BECO Helix depth filter cartridges also makes them well-suited for this application, while their backwashability, even with hot water, further extends the service-life and reduces operating costs. Eaton’s long-standing expertise Eaton’s long-standing expertise in filtration for industries like cosmetics and fine chemicals All BECO Helix depth filter cartridges provide a beta ratio of ≥ 5,000 or a retention efficiency of ≥ 99.98%. These food-grade depth filter cartridges have been carefully developed through extensive research, drawing on Eaton’s long-standing expertise in filtration for industries such as food & beverage, cosmetics, and fine chemicals. The innovative design of the BECO Helix depth filter cartridges enables optimized filtration with extended service life, reduced operating costs, and more sustainable material use. CIP and SIP compatible backwashability CIP and SIP compatible backwashability, with a wide range of applications: BECO Helix depth filter cartridges, available in various retention rates and made from polypropylene, provide a safe and efficient solution for pre-filtration and fine filtration across diverse industries. Double depth filtration effect and maximum particle-holding capacity: The unique helix wrapping increases the filter surface area and mechanical stability, resulting in significantly improved filtration performance and extended service-life for the depth filter cartridges.

GlobalLogic Inc., a Hitachi Group Company and pioneer in Digital Engineering, announced availability of technology accelerators that significantly reduce time to market of custom Over-The-Top (OTT) applications by as much as 30 to 50 percent. This is accomplished through the development of advanced solution accelerators for application development and testing across all major mainstream OTT platforms. GlobalLogic delivers this capability through a software engineering team with deep expertise in the end-to-end OTT value chain, which has developed more than 200 complex applications over the past ten years as part of multiple global OTT services rollouts. OTT Digital Accelerators The world of streaming applications has become immense and complex. Consumers demand high-quality, immersive viewing experiences from any provider on any device. To satisfy this demand and increase consumer engagement, OTT service providers must develop extremely efficient, native application experiences across multiple platforms, including living room (Smart TV, Streaming Device), mobile, web and gaming environments. Faster development of OTT services GlobalLogic OTT Channel Development Accelerator and TestLab are two such accelerators enabling GlobalLogic clients Streaming applications must be highly reliable and resilient, to assure content will be available 24/7. And systems must be robust to enable providers to monetize the service. Global rollouts add additional complexity to the entire development process. Over the last ten years, GlobalLogic has been delivering custom OTT platform application development services for more than 20 streaming platform customers—resulting in the creation of best practice frameworks and accelerators for faster development of OTT services. The GlobalLogic OTT Channel Development Accelerator and TestLab are two such accelerators enabling GlobalLogic customers such as media companies to create exceptionally reliable, immersive experiences for consumers. Management of multiple devices The accelerators are platform-agnostic—compatible with the most commonly used consumer streaming services—as well as device-agnostic, supporting gaming consoles, set-top boxes, smartphones, PCs, and tablets. They also support management of multiple devices from a single interface. OTT Channel Development Accelerator: A customizable media platform that enables the creation of a fully functional, completely branded OTT channel or app from idea to launch-ready in just 2.5 months. Key Features and Benefits: Common code base for native applications on similar platforms Support for all VOD models (AVOD, SVOD, TVOD) Advanced, customizable UI/UX features such as unlimited screens or background video Versatile monetization options such as in-app purchases, subscription billing, or ad-based services Code base owned by client with flexible GlobalLogic engagement models OTT TestLab Accelerator: A unified infrastructure that schedules automated quality assurance tests on all OTT devices. Clients can test on their own devices, or leverage GlobalLogic’s devices and labs. This is further enhanced by custom, automated test cases for all major platforms and use cases. Key Features and Benefits: Makes testing possible as soon as the channel development project begins Jump starts continuous integration/continuous delivery (CI/CD) pipelines Simple KPI set up and viewing with easy app adjustment capabilities based on results Eliminates the need to purchase duplicate equipment dedicated to each device 3,000+ test devices spanning all major platforms, vendors, use-cases OTT application landscape “The OTT application landscape has grown dramatically larger and more complex over the past few years, and our clients are seeking partners to help navigate it,” said Arun Mukunda, VP and Global Head, Media and Entertainment, GlobalLogic. “Having delivered hundreds of complex OTT applications, GlobalLogic is in a unique position to help our clients rapidly create and launch high quality streaming services on a global scale at a pace never before possible.”

The surge in demand for Category 3 Control fire performance cables used in critical situations can only help to meet safety compliance requirements, says pioneering cable supplier AEI Cables. The systems powered by these cables – including smoke and heat extraction systems – assist fire services in firefighting and a safe evacuation in the case of life safety. Selection and installation of cables AEI Cables has been highlighting the importance of following the technical guidance for the selection and installation of cables for Category 3 Control fire performance cables under the revised British Standard BS8519: 2020 Code of Practice. These cables reduce harmful smoke, toxic gases and flame spread in the event of a real fire. Stuart Dover, General Manager of AEI Cables, said: "We are seeing quite an increase in demand for Category 3 Control cables and perhaps the information to use these cables for a specific safety reason is getting through to the supply chain." Guidance for Category 3 Control fire performance The guidance for Category 3 Control fire cables applies to evacuation alarms for the disabled in care homes Stuart Dover adds: "There can be no compromise when it comes to the selection of cables for these critical applications. We offer our comprehensive range of Category 3 Control backed up with our technical support and guidance for these specific uses." The guidance for Category 3 Control fire performance cables applies to evacuation alarms for the disabled in care homes, emergency voice communications systems and voice alarm systems in relevant buildings including tall buildings, office spaces, hospitals, shopping malls and stadia. AEI Cables’ products AEI Cables’ Firetec Enhanced cabling has been approved and certified by LPCB to BS8519 (Annex B), Category 3 Control in addition to Category 2 Control. The BS Code of Practice under BS8519 contains six categories of cables, three for power cables and three for control cables each covering survival times of 30, 60 or 120 minutes. All AEI Cables’ products are supplied with approvals from independent bodies including BASEC and LPCB. It also holds approvals from organizations, including Lloyds, the MoD, Network Rail and LUL and works to international standards around the world.

Expert Commentary

Fleet electrification provides opportunities to achieve climate goals while delivering social, financial, and environmental benefits to individuals, businesses, and communities, but the road to successful EV implementation is not without obstacles. Your EV fleets need to work — all the time under varying conditions — to ensure optimal uptime while maintaining energy efficiency. Consequently, electric vehicle service equipment (EVSE) can’t just be “tacked onto” your existing operation. Rather than a “new standalone addition,” it requires a thoughtful and forward-looking approach to seamlessly integrate into your overall facility. Ensuring the type of reliable power needed for an electrified fleet is critical. Luckily, there are a number of new and emerging solutions that promise to deliver clean and reliable local power generation. The Challenges The availability and reliability of the power needed to support electrified fleets is a primary roadblock for many commercial fleet operators. It’s important to look at where that power comes from, how much it will cost, and whether it will be available when needed. Projections indicate that the demand for electricity will surge by 50% during the next two decades Today’s energy landscape is complex. Projections indicate that the demand for electricity will surge by 50% during the next two decades, with no signs of slowing down. According to Grid Strategies, the U.S. electric grid is not prepared for this level of significant load growth. The sheer amount of power needed to keep trucks charged and running 24/7 can be substantial. This poses a key risk for reliability in EV infrastructures, particularly in mission-critical situations. In addition, most fleet operators have become accustomed to fairly predictable fuel costs, since many take advantage of long-term supply arrangements. By contrast, electricity grid costs can vary and result in unpredictable spikes. This adds an extra layer of complexity when it comes to the planning and timing of fleet charging. As a result, many fleet charging operations are turning to local power generation. Intelligent Microgrids, the Energy Insurance Microgrids are nothing new, with rural communities relying on them for decades. Increased affordability and shifting regulations are allowing for more of these microgrids to be powered by renewable energy methods. A common misconception is that microgrids can completely off-set power from the grid. In reality, they are designed to provide peak load shaving and system resiliency. Coupled with an EV infrastructure, microgrids can offer more flexible and reliable energy management. When compared to a traditional microgrid for a building system, microgrids for fleet electrification present new challenges. Most notably, microgrids for fleet electrification are not modeled on an existing load, but rather anticipated demand, which can make reliable load-based modeling more difficult. However, an "intelligent" microgrid uses control systems to manage, store, charge, and discharge energy across the system. Strategic energy management The system can buy power from the grid during low-cost periods while storing self-generated solar power These controls monitor supply and demand, track real-time electricity prices, and create efficient charging schedules, considering factors like Time of Use (TOU) and peak day rates. For example, when electric fleets plug in, demand may increase significantly overnight, making strategic energy management crucial. The system can buy power from the grid during low-cost periods while storing self-generated solar power for later use. When prices rise, it discharges stored energy, keeping costs stable. It can also operate independently, ensuring continuous power during outages and disruptions, improving efficiency, cost control, and reliability. Conversely, fleets often permit charging flexibility within defined boundaries, providing a unique dispatchable resource that can be tuned to fit the needs and energy resources of the customer. A New Category of Local Power Generation Linear generator technology is proving to be an innovative solution for EV infrastructures by providing flexible, resilient and cost-effective on-site base load power. Linear generator technology provides fuel-flexibility meaning they can directly run and switch among traditional fuels like natural gas or propane. Or, they can use low and zero-carbon fuels such as RNG, biogas, hydrogen, and ammonia. Its backup capabilities ensure power through hurricanes, sub-zero snowstorms, excessive heat, and other extreme conditions. Based on capex and operating costs, linear generators can provide a competitive levelized cost of ownership compared to grid power or other alternatives in certain regions. Net-zero goals These solutions allow for flexibility and integration of new fuels as they become available The technology can also be quickly deployed at scale, which is ideal for large fleet operators looking to quickly and cost-effectively deploy resilient EV charging infrastructure while reducing emissions and working toward net-zero goals. What’s more, linear generators deliver a more “future-proof” path. While the dominant sources of fuel for local power generation today is well understood, new and exciting fuels are on the horizon. These solutions allow for flexibility and integration of new fuels as they become available. All without having to replace or retrofit existing equipment. Experts Will Power the Future As companies look to integrate EVs into their operations, a well-thought-out plan for infrastructure is essential to ensure safety, reliability, and long-term success. The integration of onsite power systems will play a critical role in optimizing energy use, lowering costs, and maintaining system resilience. The good news is that energy management is becoming more flexible, ensuring that fleet electrification is not only sustainable but also cost-effective. To ensure a seamless transition and maximize the benefits of fleet electrification, many companies will be moving forward by working with experienced consultants and planners to create a future-proof infrastructure that meets both operational and environmental goals.

Power Beat

Electricians play a pivotal role in preventing electrical fires by following safe practices during installations, repairs, and inspections. At a minimum, electricians should ensure all electrical wiring and components are installed according to current building codes and manufacturers' specifications. This includes using the right size wires for the amperage load, using approved materials, and properly securing all connections. During electrical inspections, electricians should identify and address any potential fire hazards. Electricians can also advise homeowners on electrical safety measures they can take to prevent fires. These include safe appliance use, avoiding overloaded outlets, and the importance of smoke detectors and fire extinguishers. Maintenance of electrical systems Ground Fault Circuit Interrupters (GFCIs) can prevent possible fires. GFCI outlets have built-in protection to detect imbalances in electrical current and quickly shut off power to prevent shocks and potential fires, particularly in areas prone to moisture like kitchens and bathrooms. Regular maintenance of electrical systems is also crucial for fire prevention. Electricians can perform preventative maintenance checks to identify and address any developing issues before they become serious fire hazards. Fire departments responded to an average of 32,160 home fires involving electrical distribution Fire departments responded to an average of 32,160 home fires involving electrical distribution and lighting equipment each year in 2015–2019, according to the National Fire Protection Association (NFPA). Electrical fires cause scores of civilian deaths and hundreds of civilian injuries, as well as millions of dollars in property damage. Fire Hazards in the Home Some of the electrical components that present fire hazards in the home include faulty electrical outlets and switches, worn or damaged components, overloaded circuits, damaged or frayed cords, and misused extension cords and power strips. Improper use of light fixtures can also be a danger, and space heaters can be a fire hazard if they are placed too close to flammable materials or left unattended. Damaged or frayed cords can cause sparks and ignite nearby flammable materials As outlets and switches age, the wiring behind them can loosen and break, causing sparks and fire. Loose plugs can also overheat and ignite surrounding materials. Plugging too many appliances into a single outlet or using extension cords instead of proper wiring can overload a circuit, thus causing overheating and fires. Damaged or frayed cords can cause sparks and ignite nearby flammable materials. Cords that are kinked, pinched, or have exposed wires should be avoided and replaced immediately. Minimizing the Risk of Electrical Fires Here are some steps a homeowner can take to minimize the risk of fire from electrical systems: Upgrade the electrical system, especially if the home is older. If the electrical system has not been updated in a while, a qualified electrician can advise if it needs modernization. This could involve upgrading to breakers with better safety features such as Arc-Fault Circuit Interrupter (AFCI) and Ground Fault Circuit Interrupter (GFCI) technology. Schedule an electrical safety inspection. Having a qualified electrician periodically inspect a home's electrical system can identify potential problems before they escalate into fire hazards. Keep flammable materials away from electrical components, including curtains, furniture, and piles of paper. Sparks and overheating can easily ignite nearby flammables. Addressing Multiple Threats Effective communication is key for electricians to impress upon homeowners the seriousness of fire hazards. Avoid technical jargon and explain fire hazards in clear, concise language that homeowners can understand. Focus on the potential consequences, like damage to property or injury, to heighten awareness. Pictures can be worth a thousand words. Show homeowners examples of damaged wiring, overloaded outlets, or faulty installations that pose fire risks. This can be done through photos on a tablet or phone, or even carrying around small physical samples. Frame the conversation around safety for the homeowner and their family. Highlight how addressing these hazards can prevent potential fires and ensure a safe living environment. Provide a written report after the inspection or repair. This report should detail the identified hazards, the corrective actions taken, and any recommendations for future maintenance or upgrades. By combining clear communication, visual aids, and a focus on safety, electricians can effectively convey the importance of addressing fire hazards to homeowners and empower them to make informed decisions about their electrical systems.

Rising material prices and inflation, in general, are likely to continue to plague electricians and others in the trade service businesses, according to a new survey conducted by the business management software platform Simpro. In the survey, 20% of electrical respondents say they are more likely to face rising material prices this year, while 20% of owners, CEOs, and business managers in the broader category of trade service businesses are more likely to face inflation concerns. ongoing economic uncertainty Another big concern across all trade service businesses is staff retention. Even higher percentages of survey respondents expect continuing challenges presented by the labor market: 73% anticipate hiring to be more challenging in 2023 than last year because of a lack of skilled workers (cited by 51% of respondents) and ongoing economic uncertainty (cited by 50%). The survey, conducted in January 2023, also highlighted changes trade service companies saw in the market last year compared to 2021. Customer acquisition Customer acquisition was more challenging in 2022, according to 66% of survey respondents In a service-based industry, customer satisfaction is a high priority: 95% of trade professionals noted that customer experience is paramount, and 73% have adopted technology tools specifically designed to enhance the customer experience. Customer acquisition was more challenging in 2022, according to 66% of survey respondents, while customer retention was more challenging for 60% of respondents. Hiring was also more difficult than in 2021, according to 76% of the survey respondents. Simpro’s smart technology solutions In the survey, Simpro seeks to highlight the ways technological innovations can shape the future of trade services businesses and their customers. Simpro’s total business management software platform for commercial trade service businesses performs functions such as job quoting, scheduling, inventory tracking, invoicing, and others. Simpro’s smart technology solutions and expert long-term support help businesses build, repair and power their future with control over operations. “Voice of the Trades” survey Trade professionals are estimated to spend more than 18 hours a week on tasks such as scheduling In the “Voice of the Trades” survey, 72% of trade professionals (including HVAC, security, plumbers, contractors, electricians, and others) believe that new software and technology must be adopted to remain competitive. Also, 60% feel that administrative burdens have a negative impact on their ability to service customers. Trade professionals, including electricians, estimate they spend more than 18 hours a week on tasks such as scheduling, inventory, invoicing and overall workflow management. The report reveals why it is so hard to find a contractor or service technician right now: 49% of respondents share a belief that time on admin has directly contributed to that customer frustration. Clear roadmap for operational efficiency “The Voice of the Trades findings confirm the need for trade businesses worldwide to implement technology solutions to lessen the burden of business management in any economy,” said Gary Specter, CEO of Simpro. “This research provides a clear roadmap for improving operational efficiency so trade organizations can better serve their customers.” The report gleaned feedback from 840 respondents who are trade industry professionals, with a geographic pool that includes the U.S., U.K., Australia, New Zealand, and Canada. Founded in 2002 by an electrical contractor and headquartered in Brisbane, Australia, Simpro supports more than 8,000 businesses and 200,000 users worldwide in the electrical, plumbing, HVAC, security and fire protection industries with 700-plus employees in six offices around the world.

According to a report from the North American Electric Reliability Corporation (NERC), large parts of the United States are at either ‘high’ or ‘elevated’ risk of electricity shortfalls this summer. Notably, a large swath down the middle of the country, including the Midwest US region, faces a potential for insufficient operating reserves of electricity in normal peak conditions. Electricity shortage in peak summer months Furthermore, most of the states west of the Mississippi have a potential for insufficient operating reserves in above-normal conditions. With the beginning of the 2022 summer cooling season marked by some of the highest daily temperatures on record, the ‘above-normal’ conditions are less a possibility than a probability. In affected areas, the power grid could be forced to impose rotating blackouts on some of the hottest days of the year. Most of the Eastern United States of America appears to have sufficient operating reserves to meet demand. Lagging transition to 100% clean energy The underlying causes of the electricity shortage include a lagging transition to 100% clean energy The underlying causes of the electricity shortage include a lagging transition to 100% clean energy. While efforts continue to stimulate the next generation of renewable technologies, the development is not keeping up with the growing demand for electricity. Some resources necessary to maintain sufficient electricity supplies, including natural gas and carbon-based fuels, have been targeted by activist interest groups. Beyond the recent shutdown of coal and nuclear plants, factors in the shortage include planned maintenance and forced outages, as well as low wind conditions. Implementing new technologies Utility companies are caught in the middle, seeking to satisfy consumer demand, while implementing new technologies, such as next-generation nuclear, carbon and direct air capture, energy storage, hydrogen, geothermal, and other technologies. In the words of California Gov. Gavin Newsom, who stated “However, the situation deals (not) in ideology, (but) in reality.” NERC’s Annual Reliability Assessment NERC’s Annual Reliability Assessment covers four months (June through September) and evaluates electricity generation resources, transmission system adequacy, and energy sufficiency, in order to meet projected summer peak demand and operating reserves. It identifies potential reliability issues of interest and regional topics of concern. In the U.S., the Midcontinent Independent System Operator (MISO) faces capacity shortfalls in its North and Central areas, resulting in a high risk of energy emergencies during peak summer conditions. Across the MISO, peak demand projections have increased by 1.7% since last summer, as normal demand patterns resume after the COVID-19 pandemic. Another problem is 2.3% less generation capacity when compared to the summer of 2021. In Canada, the anticipated resource capacity in Saskatchewan will be strained to meet peak demand projections, which have increased 7.5% since 2021. Drought conditions contribute to electricity shortage Drought conditions also contribute to the problem, affecting wide areas of North America Drought conditions also contribute to the problem, affecting wide areas of North America and challenging electricity supplies, and having potential impacts on demand. Energy output from hydro-generators throughout most of the Western United States of America is affected by widespread drought and below-normal snowpack, according to NERC. Suppliers of electricity from coal-fired generators are having difficulty obtaining fuel and non-fuel consumables, as supply chains are stressed. Electricity suppliers at the risk of cyber security threats Furthermore, electricity is among the critical infrastructure sectors at risk of cyber security threats from Russia and other potential actors, amid heightened geopolitical tensions. Energy efficiency goals, such as those undertaken by the HVAC industry’s transition to electric heat pumps, can contribute to minimizing the need for electricity, especially helpful during a shortage.

Case studies

RO Capital Partners (“ROCP”), the RO Group’s venture capital arm, announces that its portfolio company, measurable.energy, has installed its smart power sockets in the office of PKF Francis Clark in Bristol. PKF Francis Clark is an award-winning firm of chartered accountants and business advisers. measurable.energy is a UK tech company that designs and manufactures smart, machine-learning-enabled power sockets that will reduce the energy costs of PKF Francis Clark’s Bristol office by more than 20%. PKF Francis Clark is located at 90 Victoria Street in that city, an office building comprising 24,377 sq. ft. of high-quality office accommodation across four storeys. Small Power energy use Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type measurable.energy’s solution eliminates ‘Small Power’ waste, which is energy not required by devices that are plugged in or directly wired; such as printers, AV equipment, chilled and hot water taps, monitors, and heaters, and which are often left fully on or in standby mode overnight. Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type of ‘Small Power’ energy use. Edward Rowlandson, Group Managing Director, the RO, said: "We are very pleased to have installed measurable.energy’s technology in our flagship Bristol property for a key tenant, PKF Francis Clark. We acquired 90 Victoria Street in Bristol in April 2023, and ROCP’s investment into Reading-based measurable.energy was also made early in 2023." PKF Francis Clark’s values Rowlandson added: “That investment was driven by the need to reduce energy, and we are delighted that PKF Francis Clark’s values align with our own, and that of measurable.energy. We look forward to seeing their simple solution for office occupiers who are under pressure to take action, cut energy costs, and reduce emissions installed in more properties around the country, as the business looks to scale.” CEO and Co-Founder of measurable.energy, Dan Williams said: “My electricity-saving message to companies is to not be fooled by the small size of certain devices. A very high percentage of an office occupier’s electricity bill hides in the shadows, among small gadgets and forgotten chargers." Power usage patterns Williams added:"This silent power drain adds up faster than tenants think, and without ever realizing it. Powered by machine learning, our plug sockets will automatically identify and eliminate ‘Small Power’ waste for PKF Francis Clark, turning every appliance in their Bristol office into a cost-saving superhero.” Jim Solomon, Regional Facilities Manager at PKF Francis Clark concluded: “Since deploying measurable. energy's AI-powered sockets, we have not only reduced our office's energy consumption of the devices using the sockets by 38%, but have also gained invaluable insights into our power usage patterns. This technology has been instrumental in our efforts to operate more sustainably and efficiently.”

Mota-Engil, a multi-national with activities focused on the construction and management of infrastructures, responsible for the construction of the Canoas wastewater lifting station, selected WEG as the provider of a large package of electrical solutions for an important initiative to decontaminate the waters of the Bogotá River, in Colombia. Sustainable development When the project is completed, the pumping station will receive the wastewater from approximately 70% of the city, corresponding to the Fucha, Tintal, and Tunjuelo river basins, and the wastewater from the Municipality of Soacha, to be later pumped to the future Canoas Wastewater Treatment Plant, which will be one of the largest in Latin America. This great milestone will make it possible to return quality water to the Bogotá River and guarantee the sustainable development of the country. Safe distribution of energy Seventeen medium voltage switchgears were also supplied in addition to low voltage load centers One of the great challenges of this project is to guarantee the safe distribution of energy to the electrical systems and motors. For this, WEG has supplied a complete 115 kV substation that includes two 30 MVA/115/13.2 kV transformers, adding more efficiency and reliability to the plant. 17 medium voltage switchgears were also supplied in addition to low voltage load centers. For this project, WEG will also be supplying six three-phase induction motors and six medium voltage variable frequency drives. Each 4,300 kW motor, vertically mounted, will be coupled to its respective pump and will be responsible for pumping 6.4 cubic meters of wastewater per second to 51.6 meters height from the well, one of the most critical processes in the plant. Improvement of the quality of life This demonstrates the company's ability to develop integrated solutions that meet the most diverse applications. With participation in other important projects in the water and wastewater segment, in various processes such as potable water treatment plants, wastewater treatment, and distribution systems, WEG reinforces its experience in this segment by being selected for this important project, thus contributing to the improvement of the quality of life of the population and the environment.

WEG stands out once again by supplying a large custom-built induction motor for an Integrated Steel Plant in the Eastern part of India, in the state of Odisha. The induction motor of the MGW line, 26 MW/4 Poles/11 kV, is the largest ever manufactured in WEG's manufacturing site in India for the Indian market, it was selected to drive the main air compressor of the oxygen plant, essential for the operation of the entire Phase-1 of the steel production plant. challenges of interchangeability The project involved replacing an existing motor at the plant, a complex task that required technical expertise to overcome the challenges of interchangeability of the new motor with the existing structure. For this, it was essential to combine all the dimensions of the machine, ensuring that no modifications were necessary on-site or in the foundation. From the water inlet and outlet to the oil lines, cable entry points and shaft details, each element was carefully considered for an efficient transition. WEG supplies induction motor System criticality has been significantly minimized, eliminating the need for complex maintenance The choice of an induction motor not only met the technical demands, but also offered substantial advantages over synchronous motors, commonly used for this application because induction motors are rare in this size and power. System criticality has been significantly minimized, eliminating the need for complex maintenance associated with components such as the exciter and exciter panels, as well as delicate integration with motor and rotor telemetry systems. WEG's commitment The reliability of WEG's induction motor was a key element in keeping production running smoothly. Since the motor was installed, the steel plant has not experienced any unplanned downtime in the last one year of operation, contributing to a continuous and efficient production environment. With WEG's commitment to offer technological and reliable solutions to the market, this association not only increases the productivity of the plant, but also contributes to increasing the steel production capacity on Indian soil.

Oshkosh Airport Products, a division of Pierce Manufacturing Inc., a subsidiary of Oshkosh Corporation announces Airservices Australia has issued a purchase order for four Oshkosh Airport Products Striker® Volterra™ 6x6 Aircraft Rescue and Fire Fighting (ARFF) hybrid electric vehicles. These environmentally advanced fire apparatus will be deployed at the new Western Sydney International Airport (WSI), set to open in 2026. Striker Volterra 6x6 The Striker Volterra 6x6 comes equipped with an Oshkosh-patented hybrid-electric drivetrain, featuring an electro-mechanical infinitely variable transmission. This enables zero-emissions operation through the integrated onboard batteries and uninterrupted power supply by coupling with the internal combustion engine for pumping and drive systems. innovative design Airservices Australia is making a significant investment to support the development of an “airport of the future” WSI is a transformational infrastructure project expected to boost economic activity, provide local employment opportunities, meet Sydney's carbon-neutral sustainability initiatives, and meet the area’s growing aviation needs. Airservices Australia is a government entity making a significant investment to support the development of an “airport of the future,” featuring world-pioneering technology, innovative design, and a sustainability plan incorporating assets like the Striker Volterra ARFF hybrid electric vehicles. sustainability "As the first airport built in Australia in over 50 years, WSI is not just an airport; it's a statement of intent for a more sustainable future,” said Dave Archer, Vice President of Engineering for Oshkosh Vocational. He adds, “The Striker Volterra vehicles, with their hybrid electric technology, align perfectly with Airservices Australia and WSI’s goals. These vehicles are not only an asset to emergency response capabilities but also play a crucial role in larger environmental sustainability initiatives." environmentally conscious choice Dave Archer continues, "They symbolize a dedication to intelligent design, energy optimization, fire crew safety and efficiency, and ultimately, a carbon-neutral future." Striker Volterra ARFF hybrid electric vehicles demonstrate the most advanced acceleration and reduced fuel consumption compared to our standard diesel models, making them an environmentally conscious choice for emergency response services. Striker Volterra features Striker Volterra ARFF demonstrates a 28 percent improved acceleration compared to the standard diesel models WSI’s four new Striker Volterra 6x6 vehicles will feature an industry-pioneering modular cab design, TAK-4® all-wheel independent suspension, and a 50’ Snozzle® High Reach Extendable Turret. They each house an 11,356-liter (3,000-gallon) water tank, a 1,590-liter (420-gallon) foam tank, and a 7,570 lpm (2,000 gpm) water pump, along with a 250 kg (550 lb.) dry chemical powder system. Accelerating from 0 to 80 kph (0 to 50 mph) in under 25 seconds, the Striker Volterra ARFF demonstrates a 28 percent improved acceleration compared to the standard diesel models when fully loaded. training, implementation, and service support Dave Archer added, “The collaboration between Oshkosh Airport Products and Airservices Australia marks a significant step forward in the aviation industry's commitment to sustainability. We remain committed to a strong partnership, providing world-class training, seamless implementation, and unwavering service support to ensure these vehicles exceed expectations in the critical missions of ARFF crews.” By leveraging new technologies and innovations like Oshkosh Airport Products’ Striker Volterra ARFF hybrid electric vehicles, WSI will showcase the feasibility of low-carbon operations and set a new standard for airports worldwide.

DNV is pleased to have supported a landmark solar and storage project in the Republic of Palau in the Western Pacific region. Philippines-based power producer - Solar Pacific Energy Corporation (SPEC), the solar developer of listed Alternergy Holdings Corporation, appointed DNV as Owner’s Engineer for the 15.3 MWp solar power and associated 13.2 MWh battery energy storage system (BESS) in Ngatpang state on Babeldoab, the largest island in the Palau archipelago. The USD 29 million project, which is jointly owned by SPEC and its listed parent – Alternergy, will meet more than 20% of Palau’s energy needs. SPEC was awarded a long-term power supply agreement by the Palau Public Utilities Corporation (PPUC) to feed power to the central grid in Badelboab. The power plant was inaugurated last June 2. DNV’s work scope for the solar + BESS hybrid system DNV assessed if the design would meet two main purposes: grid smoothing and energy generation DNV’s work scope for the solar + BESS hybrid system, SPEC’s first venture into overseas markets, spanned four phases across the design, pre-construction, construction, and project completion stages. DNV assessed if the design would meet two main purposes: grid smoothing and energy generation. It advised on project scheduling and progress tracking, and checked the engineering, procurement and construction (EPC) contract on SPEC’s behalf. “Solar Pacific is grateful to DNV for its excellent technical and project management support throughout the pre-construction and implementation stages of this exciting project. DNV provided valuable expertise to ensure the delivery of a rather complex project that involved a PV and battery storage hybrid solution on a challenging project site located in a remote location. We look forward to expanding our working relationship with DNV throughout the Asia Pacific region,” said Mike Lichtenfeld, the Chief Executive Officer (CEO) of Solar Pacific Energy Corporation (SPEC). DNV, Alternergy and SPEC partnership “Alternergy is delighted to conclude another successful renewable project with DNV,” said Gerry Magbanua, the President of Alternergy, adding “Since 2014, we have collaborated with DNV in developing our pioneering wind and solar projects in the Philippines.” Project construction management was conducted remotely from DNV’s Singapore office Project construction management was conducted remotely from DNV’s Singapore office, with DNV’s partner providing onsite construction personnel supervised and managed by DNV and owner’s site representatives (OSRs) for both the civil and electrical engineering aspects. The OSRs monitored construction and with input from DNV specialist engineers, delivered several monitoring, inspection, verification, witnessing and testing activities during construction, commissioning, testing and energization of the system. DNV inspections post-commissioning DNV inspections post-commissioning ensured that non-conformance with contract specifications was sufficiently rectified, before certifying the project as ready for handover and issuing the Final Completion Certification. According to DNV’s latest Energy Transition Outlook report, Southeast Asia will see solar PV and solar coupled with storage play a significant role in the region’s electricity generation share, rising sharply from the late 2030s to generating 74% of the electricity by 2050.

Located on the Red Sea coast of Saudi Arabia, Yanbu is the nerve center of the Kingdom’s petrochemicals industry. One of Yanbu’s critical installations is the power station, which has several Gas Turbine Generators (GTGs) with a total capacity of 524.6MW. The power station caters to the region’s total electricity demand. DG sets In case of any unexpected shutdown, the GTGs are restarted by DG sets designed specifically for Black Start applications. The DG sets are supplied by Saudi Diesel Equipment Co. Ltd., a well-known local manufacturer, and supplier to the oil and gas industry since 1978s. The new DG sets are supplied to replace a 35 years-old existing DG sets based on a detailed assessment by the company responsible for the maintenance of the power station. Entrusted with the task, Saudi Diesel opted for alternators from Nidec Leroy- Somer, its trusted supplier. DOL starter motors Given the critical nature of the project, the company ordered two DG sets for redundancy and reliability The GTGs are equipped with DOL starter motors of 600kW, 4.16kV rating, and the starting current is very high, 6 times the nominal current which means there is a huge inrush current experienced by the alternator. Given the critical nature of the project, the company ordered two DG sets for redundancy, and thereby, reliability. Black Start The DG set first acts as a Black Start and is primarily responsible to start the turbines that are down or under planned maintenance shutdown. The DG set is also used to feed auxiliary loads in case the need arises for emergency loads other than the turbine load, before or after the Black Start, till such time the turbines take over the full load. Challenge For Nidec Leroy- Somer, the challenge was to design a medium voltage 4.16kV alternator with a rated power of 4000kVA. This is a high-speed alternator, IP23 rated, so there were some constraints regarding the design of the machine. An important consideration was adapting the design to the ambient temperature of 50°C with the humidity reaching 100% in consideration of the very harsh environment at the site. D550 digital AVR AVR has functionalities including online monitoring with manual and remote controls Nidec Leroy- Somer also used the latest D550 digital AVR, which is ideal for parallel genset operation. The AVR also has a wide range of functionalities including online monitoring with manual and remote controls. The two alternators were designed and manufactured after a thorough calculation of all electrical parameters following detailed discussions with the client before finalizing the design. Once assembled, the alternators were tested and approved by Saudi Diesel along with third-party inspectors, a prerequisite for any machine exported to Saudi Arabia. synchronous speed “Any application that involves a power plant is very critical, because in case of a shutdown, the unit has to restart and come online as fast as possible, and these are very heavy turbines, each of 50MW. Also, they must run to a synchronous speed before energizing the equipment and connecting to the grid. That is the critical part, getting the GTGs into a synchronous speed before connecting to the grid,” says Nawar Shubber, Regional Sales Manager at Nidec Leroy-Somer. complete packaged units The two DG sets were supplied as complete packaged units, each measuring 13mtr (L) x 5mtr (W) x 6 meters (H) in dimensions. The diesel engine is from MTU, Germany. Each package is a complete unit with the Engine coupled to the Alternator, Diesel Tank, MV Switchgear, 480V Motor Control Center (MCC), Control Panel, Fire Alarm, Suppression System, and Radiator Cooling System. axial up-blast fans Two axial up-blast fans have been installed for ventilation purposes during operation to maintain the temperature rise inside the enclosure within 5-degC. The ingress protection rating during standby time for the whole package is IP56. The packages are based on a plug-and-play concept easy to install, easy to run, and easy to maintain. gas-tight enclosure Enclosures for the entire generator set, fabricated locally, contain UL-motorized louvers" “Enclosures for the entire generator set, fabricated locally, contain UL- motorized louvers for totally enclosed operation during shut-down. The package is designed as a gas-tight enclosure while the fire alarm and suppression systems in these units are tested by NFPA 2001 and BS EN 15004-1,” says Kathim Alrifai, Project Manager at Saudi Diesel Equipment Company. generator Apart from the harsh environment, the project is also located within a high seismic zone. The generator is mounted on dual spring and rubber vibration isolators designed to withstand earthquakes and seismic activity within specific limits, as determined by the data applicable to the city.