Artificial Intelligence

In the ever-evolving landscape of electrical services, the journey towards condition monitoring represents a significant leap forward. Now, customers face challenges, such as aging workforce and infrastructure, rising cost of energy and operation, and lack of transparency to the condition of key building systems. Dealing with these challenges will require a transformation driven by the need for enhanced reliability, efficiency, and safety in electrical distribution systems, with increased autom...

Delta, a global pioneer in power management and smart green solutions, highlighted at Hannover Messe 2025 a versatile set of AI-driven smart manufacturing, energy infrastructure, and data centre solutions. These include, the award-winning D-Bot series cobots, featuring advanced cognitive capabilities and integration with NVIDIA Omniverse to develop next-generation digital twins; and DeltaGrid®, the AI-enabled energy management platform to optimize efficiency in the energy infrastructure sup...

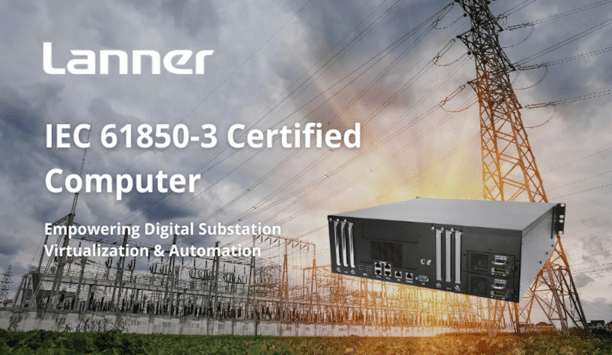

Lanner Electronics, a global pioneer in industrial computing and network security solutions, proudly announces the launch of the ICS-P770. An IEC 61850-3, IEEE 1613, and EN50121-4 certified industrial grade computing platform designed to power mission-critical substation automation, virtualization, and network security. Powering Digital Substations The ICS-P770 is a rugged 3U rackmount industrial computer built to handle the demands of digital substation automationThe ICS-P770 is a rugged 3U...

Lanner Electronics, a pioneer in network computing appliances and industrial AI computers, will officially unveil its latest innovation, the EAI-I233 and EAI-I251 industrial-grade Edge AI computers, at NVIDIA GTC 2025. Powered by the NVIDIA® Jetson AGX Orin™ system on module (SOM), these advanced platforms are designed to deliver low-latency AI inferencing capabilities at the edge for industries including retail, manufacturing, transportation, and smart city. EAI-I233: AI inference s...

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, unveiled its broad spectrum of next-generation power and liquid cooling solutions at NVIDIA GTC 2025. These solutions are designed to bolster the performance and energy conservation in NVIDIA-enabled AI and HPC data centers, including the newly launched Power Capacitance Shelves and in-row 1.5MW liquid-to-liquid Coolant Distribution Units (CDU). NVIDIA Omniverse™ platform Delta’s AI-based Smart...

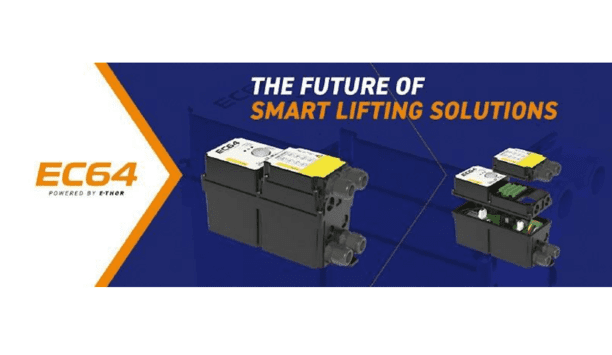

After a period of development, EdmoLift introduces EC64, an innovative and future-proof electrical control system. With a modular design and smart features. The new electrical control system is designed to meet both current and future needs. The initial sales launch will take place on June 1, 2025. Future Ready electrical control system "EC64 is the result of several years of development, combining EdmoLift’s expertise in smart lifting solutions with the latest technology". "Than...

News

As part of CORE’s annual maintenance program, an FAA-certified contractor is continuing to operate unmanned drone aircraft in the utility right-of-way in the Greenland-Palmer Lake area now through February. The drones will be used to visually inspect roughly 1,700 poles and electrical equipment, after which CORE crews and contractors will make repairs to any identified deficiencies. Along with their drone contractors, they will likely see CORE lineman inspecting poles and equipment on foot. They use their drone and foot patrol simultaneously to be as efficient and thorough as possible. CORE is committed to maintaining a safe and reliable system. They appreciate users' understanding while they complete this important work.

The U.S. Air Force (USAF) has selected Verizon Business to install 5G and/or 4G LTE network enhancements on 35 Air Force installations located throughout the United States. network solutions Through the Air Force’s Offer to Lease (OTL) program, Verizon Business will deliver network enhancements like C-Band carrier adds, new macro builds, and small cells. Verizon’s network solutions will bring higher speeds, increased bandwidth, and lower latency for base personnel and the surrounding community, contributing to the diverse missions at each base while also enhancing the quality of life for personnel and military families. Offer to Lease (OTL) program “This is Verizon’s 7th OTL win out of 8 attempts, which serves as a testament to the trust the U.S. Air Force has in the strength and speed of our network, as well as the quality of the professional and managed services expertise they gain from our people,” said Maggie Hallbach, senior vice president, Verizon Public Sector. “We are honored to have Verizon Business serve as one of their most trusted partners.” Verizon’s 5G portfolio The award builds on Verizon Business’s recent momentum with the U.S. Air Force The Air Force bases are located in Alabama, Alaska, Arkansas, California, Delaware, Washington, D.C., Florida, Idaho, Illinois, Kansas, Louisiana, Maryland, Massachusetts, Michigan, Mississippi, Missouri, Montana, New Hampshire, New Jersey, New York, Ohio, Oklahoma, Texas, Virginia, and Washington. The award builds on Verizon Business’s recent momentum with the U.S. Air Force and broadens Verizon’s 5G portfolio with the federal government, and the U.S. Dept. of Defense specifically. wireless improvements Titled Opportunity to Lease (OTL) 3, Groups A, B, and C, the win builds on Verizon’s OTL 1a, 1b, 2 and 2b wins in 2019, 2021, and 2023, empowering Verizon to provide wireless improvements to more than three dozen Air Force bases, including the 5G Ultra Wideband deployment work Verizon completed at Tyndall Air Force Base in Florida. Through its involvement in the OTL program, Verizon is delivering 5G and other wireless network services across 72 Air Force bases throughout the United States. digital transformation Verizon’s 5G investment in the Armed Forces is helping U.S. military leadership pursue its most strategic digital transformation priorities. This includes supporting flight line test equipment, animated simulation, and training, full-motion, high-definition video to support telemedicine for its airmen, and ultra-fast artificial intelligence for biometric identification.

GlobalLogic Inc. is pleased to announce the opening of a new Security Operations Center (SOC) in Kraków, Poland that utilizes the capabilities of Hitachi Cyber. This announcement comes as organizations face a critical moment in cyber security, with the start of 2025 bringing heightened risks from AI-driven attacks, ransomware-as-a-service, and supply chain vulnerabilities. According to recent reports by ENISA, cyber incidents across Europe have doubled in the past year, and the impact on critical sectors such as healthcare, energy, and manufacturing has been profound. Additionally, according to Fortinet's 2024 Global Cyber Security Skills Gap Report, 70% of companies struggle to safeguard their assets due to a growing shortage of skilled cyber security professionals. Kraków Security Operations Center (SOC) The Kraków SOC is positioned to address these pressing challenges by providing 24/7 monitoring and tailored solutions that help organizations mitigate risks, ensure compliance with regulations like GDPR and NIS2, and build resilience against an increasingly sophisticated threat landscape. Individual approach and advanced technology The new SOC offers a unique combination of services, covering the protection of networks, servers The new SOC offers a unique combination of services, covering the protection of networks, servers, applications, devices, and processes. These solutions leverage advanced tools for detection, analysis, and response, utilizing — among other technologies — AI capabilities to precisely monitor threats. The center's offerings are tailored to the specific needs of various sectors, including finance, energy, rail, manufacturing, and healthcare. The SOC is distinguished by its customized approach and ability to address the challenges related to operational technology (OT), such as industrial equipment and information technology (IT) such as infrastructure, which requires specialized security measures. Use of advanced tools and AI The center focuses on identifying and responding to threats in OT and IT environments, taking into account differences in their architecture, protocols, and communication. Through the use of advanced tools and AI, the SOC enables the detection of unusual behaviors and rapid responses to potential attacks. In addition, it supports organizations in meeting regulatory requirements, helping them effectively mitigate risks and build resilience. Growing security needs SOC-as-a-Service offers an opportunity to quickly scale operations to cater to growing security needs The center in Kraków enables the outsourcing of SOC functions, which is particularly attractive to small and medium-sized enterprises. These organizations can benefit from a fully operational SOC without incurring the costs of building and maintaining their infrastructure. For large organizations, SOC-as-a-Service offers an opportunity to quickly scale operations in response to growing security needs. The combination of GlobalLogic’s experience in digital engineering and Hitachi’s cyber security expertise and Hitachi Europe's complex market overview enables the delivery of a unique solution: GlobalLogic Secure Application Engineering. Leverage AI to strengthen protective capabilities As part of this service, security engineers propose enhancements and ensure compliance at every stage of an application's lifecycle, leveraging artificial intelligence to strengthen protective capabilities and introduce innovative security mechanisms. This solution bridges the gap between security and efficiency-focused engineering, ensuring seamless integration throughout the process. As a result, the Kraków-based SOC offers an innovative approach to data protection. Combine cutting-edge technology with industry expertise Matt Castonguay, Chief Revenue Officer - Hitachi Systems Trusted Cyber Management, Hitachi, said “The opening of our state-of-the-art Security Operations Center in Kraków reflects Hitachi Cyber's unwavering commitment to safeguarding businesses across Europe against an ever-evolving threat landscape.” He adds, “By combining cutting-edge technology with decades of expertise, we are empowering organizations to navigate complexity, ensure compliance, and build resilience in the face of growing cyber security challenges. This initiative reinforces our vision of creating a secure digital future, where innovation and security go hand in hand.” Kraków's investment in the future This state-of-the-art center, now fully operational, is a strategic point of support for companies “The opening of the SOC in Kraków marks another step in our mission to support European companies in protecting their data and safeguarding their reputations. Utilizing Hitachi Cyber, we provide clients with comprehensive protection that not only addresses current needs but also prepares them for future challenges,” emphasizes Igor Byeda, Group Vice President, of Europe at GlobalLogic. This state-of-the-art center, now fully operational, is a strategic point of support for companies in the European region, offering scalable solutions and specialized expertise to address evolving business needs. Leverage skilled professionals and advanced technologies By leveraging the center’s skilled professionals and advanced technologies, organizations can scale their operations efficiently, while reducing reliance on internal resources and optimizing security processes, resulting in significant cost savings of £1 to £3 million annually for large organizations. Through the integration of global expertise, local resources, and advanced technologies, the newly launched SOC is an important contribution to building a secure digital ecosystem in Poland and across the continent.

Siemens is ramping up investments in the U.S. to support and benefit from America’s industrial tech growth. “The industrial tech sector is the basis to boost manufacturing in America and there’s no company more prepared than Siemens to make this future a reality for customers from small and medium sized enterprises to industrial giants,” said Roland Busch, President and CEO of Siemens AG. Recent investments of Altair The $285 million investment is expected to create over 900 skilled manufacturing jobs The U.S. is already the largest market for the company, relying on American talent and American supply chains. The recent investments in the company’s U.S. manufacturing footprint and the planned acquisition of Altair, a Michigan-based software company, amount to more than $10 billion. This week, Siemens is unveiling two state-of-the-art manufacturing facilities for electrical products in Fort Worth, Texas, and Pomona, California. The $285 million investment is expected to create over 900 skilled manufacturing jobs. Industrial AI revolution The equipment produced will support critical sectors such as the commercial, industrial and construction markets while powering AI data centers all over the country to support America’s leadership in the industrial AI revolution. With that Siemens is more than doubling its production capacity of electric equipment to power critical American infrastructure such as AI data centers. Smarter software to help design America’s manufacturing The mix with existing software from Siemens will create the world's most complete AI-powered design In October 2024, Siemens signed an agreement to acquire Altair. The combination with existing software from Siemens will create the world's most complete AI-powered design and simulation portfolio. This will allow users in America and all around the world to design and manufacture more complex and smarter products faster – by simulating in the digital world, first. They could for example do a virtual crash-test for a new car design; or calculate in advance how a cell phone reacts to drops and thus develop the design optimally, before they build it in the real world. Powerful AI tools help along the way. Innovation and strength of America’s industry “We believe in the innovation and strength of America’s industry. That’s why Siemens has invested over $90 billion in the country in the last 20 years. This year’s investment will bring this number to over $100 billion. We are bringing more jobs, more technology and a boost to America’s AI capabilities,” said Roland Busch. Siemens employs more than 45,000 people in the U.S. and is partnering with about 12,000 suppliers nationwide.

Siemens is presenting its new developments in industrial automation and digitalization for the intralogistics industry at this year's Logimat. Faced with global challenges like labor shortages, growing sustainability requirements, and demographic change, the technology company is introducing innovative automation and digitalization solutions that increase efficiency, adaptability, and sustainability in intralogistics. Siemens Xcelerator ecosystem Siemens shows in a highlight showcase how the mix of software-defined and data-driven With Simatic Robot Pick AI Pro, an industrial vision AI for the development of AI-supported picking robots, Siemens demonstrates in a highlight showcase how the combination of software-defined and data-driven automation creates more adaptability and flexibility in automation solutions in order to overcome the challenges and complexity of today's intralogistics and to offer future-proof solutions. The Siemens Xcelerator ecosystem plays a central role by promoting innovation and integration across platform boundaries, which is accelerating the transition to a Digital Enterprise. Automation for advanced robotic solutions A blueprint for software-defined automation for advanced robotic solutions for robot-based picking of small parts in the intralogistics industry The centerpiece of the showcase at the Siemens booth is Simatic Robot Pick AI Pro, a pre-trained deep-learning vision software from Siemens that enables model-free 3D robot picking of unknown objects with individually adaptable vacuum multi-grippers. Simatic Robot Pick AI Pro The software reliably delivers gripping poses for a wide variety of inventory items in milliseconds The software reliably delivers gripping poses (6-DoF) for a wide variety of inventory items in milliseconds, regardless of their shape, size, or packaging. This means that Simatic Robot Pick AI Pro will facilitate the development of cost-effective, autonomous, and scalable robot solutions for single-piece order picking for sectors like e-commerce. It also addresses the labor shortage associated with monotonous picking tasks. Siemens Industrial Operations X portfolios Simatic Robot Pick AI Pro is a solution of Siemens Industrial Operations X portfolios, which is part of Siemens Xcelerator. Siemens Industrial Operations X combines software-defined automation and data-driven solutions within industrial ecosystems aiming to make systems more adaptive. An essential component of software-defined automation is Simatic AX, a modern development environment that increases efficiency in the creation and management of both physical and virtual controls. Use of advanced technologies Use of advanced technologies like edge and cloud computing to optimize operational processes Virtual PLCs (programmable logic controllers) are also being used to provide greater flexibility and scalability in deploying control systems as software containers based on industrial edge management. Industrial Operations X integrates these technologies and enables a seamless collaboration between different systems and the use of advanced technologies like edge and cloud computing to optimize and continuously improve operational processes. With this, machine builders can develop flexible and scalable robot order-picking systems that can be adapted to meet specific requirements. Robots with Siemens AI vision software Robots with Siemens AI vision software can autonomously identify and handle a variety of unknown objects, ensuring increased flexibility and adaptability in dynamic environments. There is also a seamless integration with TIA, which ensures a continuous data flow from the robot order-picking cell to the entire operational process. Development of new solutions and technologies Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers Siemens Xcelerator offers an open ecosystem for collaboration and innovation within a network of certified partners, such as Zivid for industrial 3D cameras or Piab for vacuum tools, to support the development of new solutions and technologies. At the exhibition, Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers in code generation and fault diagnosis and facilitates the engineering of complex automation systems. Siemens Industrial Copilot for engineering complex machines With the Siemens Industrial Copilot for TIA Portal Engineering, Siemens presents the first generative AI assistant for industrial engineering. Thanks to its seamless integration into the TIA Portal, the AI assistant simplifies and accelerates development processes and significantly minimizes error sources. It also allows less experienced professionals to effectively apply their knowledge and skills.

From September 20th to 21st, Hitachi will hold the Hitachi Social Innovation Forum 2023 Japan, the largest event of the Hitachi Group, as a place to create opportunities for collaborative creation with customers and partners. The event will be held at Tokyo Big Sight. In addition to a Keynote session on Hitachi's management vision by President and CEO of Hitachi, Keiji Kojima, the Forum will showcase over 60 programs that include Special sessions to discuss various fields and business trends with industry professionals; Business sessions to engage customers, partners, and experts in meaningful debate on social issues and potential solutions; and an Interactive Exhibition where visitors can experience the latest technologies and social innovation business initiatives. Key emerging technologies This year, GlobalLogic will demonstrate key emerging technologies, including Generative AI, Metaverse, and Web3.0, and how to rapidly deploy these capabilities to boost purposeful innovation, new products, and experiences to benefit society. They can find the booth "Accelerating Digital Innovation With Purpose: Generative AI, Metaverse, Web3.0" in the exhibition hall.

As part of CORE’s annual maintenance program, an FAA-certified contractor is continuing to operate unmanned drone aircraft in the utility right-of-way in the Greenland-Palmer Lake area now through February. The drones will be used to visually inspect roughly 1,700 poles and electrical equipment, after which CORE crews and contractors will make repairs to any identified deficiencies. Along with their drone contractors, they will likely see CORE lineman inspecting poles and equipment on foot. They use their drone and foot patrol simultaneously to be as efficient and thorough as possible. CORE is committed to maintaining a safe and reliable system. They appreciate users' understanding while they complete this important work.

The U.S. Air Force (USAF) has selected Verizon Business to install 5G and/or 4G LTE network enhancements on 35 Air Force installations located throughout the United States. network solutions Through the Air Force’s Offer to Lease (OTL) program, Verizon Business will deliver network enhancements like C-Band carrier adds, new macro builds, and small cells. Verizon’s network solutions will bring higher speeds, increased bandwidth, and lower latency for base personnel and the surrounding community, contributing to the diverse missions at each base while also enhancing the quality of life for personnel and military families. Offer to Lease (OTL) program “This is Verizon’s 7th OTL win out of 8 attempts, which serves as a testament to the trust the U.S. Air Force has in the strength and speed of our network, as well as the quality of the professional and managed services expertise they gain from our people,” said Maggie Hallbach, senior vice president, Verizon Public Sector. “We are honored to have Verizon Business serve as one of their most trusted partners.” Verizon’s 5G portfolio The award builds on Verizon Business’s recent momentum with the U.S. Air Force The Air Force bases are located in Alabama, Alaska, Arkansas, California, Delaware, Washington, D.C., Florida, Idaho, Illinois, Kansas, Louisiana, Maryland, Massachusetts, Michigan, Mississippi, Missouri, Montana, New Hampshire, New Jersey, New York, Ohio, Oklahoma, Texas, Virginia, and Washington. The award builds on Verizon Business’s recent momentum with the U.S. Air Force and broadens Verizon’s 5G portfolio with the federal government, and the U.S. Dept. of Defense specifically. wireless improvements Titled Opportunity to Lease (OTL) 3, Groups A, B, and C, the win builds on Verizon’s OTL 1a, 1b, 2 and 2b wins in 2019, 2021, and 2023, empowering Verizon to provide wireless improvements to more than three dozen Air Force bases, including the 5G Ultra Wideband deployment work Verizon completed at Tyndall Air Force Base in Florida. Through its involvement in the OTL program, Verizon is delivering 5G and other wireless network services across 72 Air Force bases throughout the United States. digital transformation Verizon’s 5G investment in the Armed Forces is helping U.S. military leadership pursue its most strategic digital transformation priorities. This includes supporting flight line test equipment, animated simulation, and training, full-motion, high-definition video to support telemedicine for its airmen, and ultra-fast artificial intelligence for biometric identification.

GlobalLogic Inc. is pleased to announce the opening of a new Security Operations Center (SOC) in Kraków, Poland that utilizes the capabilities of Hitachi Cyber. This announcement comes as organizations face a critical moment in cyber security, with the start of 2025 bringing heightened risks from AI-driven attacks, ransomware-as-a-service, and supply chain vulnerabilities. According to recent reports by ENISA, cyber incidents across Europe have doubled in the past year, and the impact on critical sectors such as healthcare, energy, and manufacturing has been profound. Additionally, according to Fortinet's 2024 Global Cyber Security Skills Gap Report, 70% of companies struggle to safeguard their assets due to a growing shortage of skilled cyber security professionals. Kraków Security Operations Center (SOC) The Kraków SOC is positioned to address these pressing challenges by providing 24/7 monitoring and tailored solutions that help organizations mitigate risks, ensure compliance with regulations like GDPR and NIS2, and build resilience against an increasingly sophisticated threat landscape. Individual approach and advanced technology The new SOC offers a unique combination of services, covering the protection of networks, servers The new SOC offers a unique combination of services, covering the protection of networks, servers, applications, devices, and processes. These solutions leverage advanced tools for detection, analysis, and response, utilizing — among other technologies — AI capabilities to precisely monitor threats. The center's offerings are tailored to the specific needs of various sectors, including finance, energy, rail, manufacturing, and healthcare. The SOC is distinguished by its customized approach and ability to address the challenges related to operational technology (OT), such as industrial equipment and information technology (IT) such as infrastructure, which requires specialized security measures. Use of advanced tools and AI The center focuses on identifying and responding to threats in OT and IT environments, taking into account differences in their architecture, protocols, and communication. Through the use of advanced tools and AI, the SOC enables the detection of unusual behaviors and rapid responses to potential attacks. In addition, it supports organizations in meeting regulatory requirements, helping them effectively mitigate risks and build resilience. Growing security needs SOC-as-a-Service offers an opportunity to quickly scale operations to cater to growing security needs The center in Kraków enables the outsourcing of SOC functions, which is particularly attractive to small and medium-sized enterprises. These organizations can benefit from a fully operational SOC without incurring the costs of building and maintaining their infrastructure. For large organizations, SOC-as-a-Service offers an opportunity to quickly scale operations in response to growing security needs. The combination of GlobalLogic’s experience in digital engineering and Hitachi’s cyber security expertise and Hitachi Europe's complex market overview enables the delivery of a unique solution: GlobalLogic Secure Application Engineering. Leverage AI to strengthen protective capabilities As part of this service, security engineers propose enhancements and ensure compliance at every stage of an application's lifecycle, leveraging artificial intelligence to strengthen protective capabilities and introduce innovative security mechanisms. This solution bridges the gap between security and efficiency-focused engineering, ensuring seamless integration throughout the process. As a result, the Kraków-based SOC offers an innovative approach to data protection. Combine cutting-edge technology with industry expertise Matt Castonguay, Chief Revenue Officer - Hitachi Systems Trusted Cyber Management, Hitachi, said “The opening of our state-of-the-art Security Operations Center in Kraków reflects Hitachi Cyber's unwavering commitment to safeguarding businesses across Europe against an ever-evolving threat landscape.” He adds, “By combining cutting-edge technology with decades of expertise, we are empowering organizations to navigate complexity, ensure compliance, and build resilience in the face of growing cyber security challenges. This initiative reinforces our vision of creating a secure digital future, where innovation and security go hand in hand.” Kraków's investment in the future This state-of-the-art center, now fully operational, is a strategic point of support for companies “The opening of the SOC in Kraków marks another step in our mission to support European companies in protecting their data and safeguarding their reputations. Utilizing Hitachi Cyber, we provide clients with comprehensive protection that not only addresses current needs but also prepares them for future challenges,” emphasizes Igor Byeda, Group Vice President, of Europe at GlobalLogic. This state-of-the-art center, now fully operational, is a strategic point of support for companies in the European region, offering scalable solutions and specialized expertise to address evolving business needs. Leverage skilled professionals and advanced technologies By leveraging the center’s skilled professionals and advanced technologies, organizations can scale their operations efficiently, while reducing reliance on internal resources and optimizing security processes, resulting in significant cost savings of £1 to £3 million annually for large organizations. Through the integration of global expertise, local resources, and advanced technologies, the newly launched SOC is an important contribution to building a secure digital ecosystem in Poland and across the continent.

Siemens is ramping up investments in the U.S. to support and benefit from America’s industrial tech growth. “The industrial tech sector is the basis to boost manufacturing in America and there’s no company more prepared than Siemens to make this future a reality for customers from small and medium sized enterprises to industrial giants,” said Roland Busch, President and CEO of Siemens AG. Recent investments of Altair The $285 million investment is expected to create over 900 skilled manufacturing jobs The U.S. is already the largest market for the company, relying on American talent and American supply chains. The recent investments in the company’s U.S. manufacturing footprint and the planned acquisition of Altair, a Michigan-based software company, amount to more than $10 billion. This week, Siemens is unveiling two state-of-the-art manufacturing facilities for electrical products in Fort Worth, Texas, and Pomona, California. The $285 million investment is expected to create over 900 skilled manufacturing jobs. Industrial AI revolution The equipment produced will support critical sectors such as the commercial, industrial and construction markets while powering AI data centers all over the country to support America’s leadership in the industrial AI revolution. With that Siemens is more than doubling its production capacity of electric equipment to power critical American infrastructure such as AI data centers. Smarter software to help design America’s manufacturing The mix with existing software from Siemens will create the world's most complete AI-powered design In October 2024, Siemens signed an agreement to acquire Altair. The combination with existing software from Siemens will create the world's most complete AI-powered design and simulation portfolio. This will allow users in America and all around the world to design and manufacture more complex and smarter products faster – by simulating in the digital world, first. They could for example do a virtual crash-test for a new car design; or calculate in advance how a cell phone reacts to drops and thus develop the design optimally, before they build it in the real world. Powerful AI tools help along the way. Innovation and strength of America’s industry “We believe in the innovation and strength of America’s industry. That’s why Siemens has invested over $90 billion in the country in the last 20 years. This year’s investment will bring this number to over $100 billion. We are bringing more jobs, more technology and a boost to America’s AI capabilities,” said Roland Busch. Siemens employs more than 45,000 people in the U.S. and is partnering with about 12,000 suppliers nationwide.

Siemens is presenting its new developments in industrial automation and digitalization for the intralogistics industry at this year's Logimat. Faced with global challenges like labor shortages, growing sustainability requirements, and demographic change, the technology company is introducing innovative automation and digitalization solutions that increase efficiency, adaptability, and sustainability in intralogistics. Siemens Xcelerator ecosystem Siemens shows in a highlight showcase how the mix of software-defined and data-driven With Simatic Robot Pick AI Pro, an industrial vision AI for the development of AI-supported picking robots, Siemens demonstrates in a highlight showcase how the combination of software-defined and data-driven automation creates more adaptability and flexibility in automation solutions in order to overcome the challenges and complexity of today's intralogistics and to offer future-proof solutions. The Siemens Xcelerator ecosystem plays a central role by promoting innovation and integration across platform boundaries, which is accelerating the transition to a Digital Enterprise. Automation for advanced robotic solutions A blueprint for software-defined automation for advanced robotic solutions for robot-based picking of small parts in the intralogistics industry The centerpiece of the showcase at the Siemens booth is Simatic Robot Pick AI Pro, a pre-trained deep-learning vision software from Siemens that enables model-free 3D robot picking of unknown objects with individually adaptable vacuum multi-grippers. Simatic Robot Pick AI Pro The software reliably delivers gripping poses for a wide variety of inventory items in milliseconds The software reliably delivers gripping poses (6-DoF) for a wide variety of inventory items in milliseconds, regardless of their shape, size, or packaging. This means that Simatic Robot Pick AI Pro will facilitate the development of cost-effective, autonomous, and scalable robot solutions for single-piece order picking for sectors like e-commerce. It also addresses the labor shortage associated with monotonous picking tasks. Siemens Industrial Operations X portfolios Simatic Robot Pick AI Pro is a solution of Siemens Industrial Operations X portfolios, which is part of Siemens Xcelerator. Siemens Industrial Operations X combines software-defined automation and data-driven solutions within industrial ecosystems aiming to make systems more adaptive. An essential component of software-defined automation is Simatic AX, a modern development environment that increases efficiency in the creation and management of both physical and virtual controls. Use of advanced technologies Use of advanced technologies like edge and cloud computing to optimize operational processes Virtual PLCs (programmable logic controllers) are also being used to provide greater flexibility and scalability in deploying control systems as software containers based on industrial edge management. Industrial Operations X integrates these technologies and enables a seamless collaboration between different systems and the use of advanced technologies like edge and cloud computing to optimize and continuously improve operational processes. With this, machine builders can develop flexible and scalable robot order-picking systems that can be adapted to meet specific requirements. Robots with Siemens AI vision software Robots with Siemens AI vision software can autonomously identify and handle a variety of unknown objects, ensuring increased flexibility and adaptability in dynamic environments. There is also a seamless integration with TIA, which ensures a continuous data flow from the robot order-picking cell to the entire operational process. Development of new solutions and technologies Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers Siemens Xcelerator offers an open ecosystem for collaboration and innovation within a network of certified partners, such as Zivid for industrial 3D cameras or Piab for vacuum tools, to support the development of new solutions and technologies. At the exhibition, Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers in code generation and fault diagnosis and facilitates the engineering of complex automation systems. Siemens Industrial Copilot for engineering complex machines With the Siemens Industrial Copilot for TIA Portal Engineering, Siemens presents the first generative AI assistant for industrial engineering. Thanks to its seamless integration into the TIA Portal, the AI assistant simplifies and accelerates development processes and significantly minimizes error sources. It also allows less experienced professionals to effectively apply their knowledge and skills.

From September 20th to 21st, Hitachi will hold the Hitachi Social Innovation Forum 2023 Japan, the largest event of the Hitachi Group, as a place to create opportunities for collaborative creation with customers and partners. The event will be held at Tokyo Big Sight. In addition to a Keynote session on Hitachi's management vision by President and CEO of Hitachi, Keiji Kojima, the Forum will showcase over 60 programs that include Special sessions to discuss various fields and business trends with industry professionals; Business sessions to engage customers, partners, and experts in meaningful debate on social issues and potential solutions; and an Interactive Exhibition where visitors can experience the latest technologies and social innovation business initiatives. Key emerging technologies This year, GlobalLogic will demonstrate key emerging technologies, including Generative AI, Metaverse, and Web3.0, and how to rapidly deploy these capabilities to boost purposeful innovation, new products, and experiences to benefit society. They can find the booth "Accelerating Digital Innovation With Purpose: Generative AI, Metaverse, Web3.0" in the exhibition hall.

Case studies

Quanergy Solutions, Inc., a provider of 3D LiDAR (Light Detection and Ranging) security solutions, was chosen by Vancouver International Airport (YVR) to analyze footfall to support the passenger journey with the ultimate goal of enhancing operational efficiencies. Quanergy’s technology is delivering accurate data-driven insights for YVR’s Domestic Check-in and Security Screening facilities. Real-time insights “Through the implementation of Quanergy’s solutions, we have harnessed the power of real-time insights, gaining a deep understanding of passenger volumes and the associated wait times at different stages of their journey through the terminal,” said Jason Williams, Manager of Innovation & Technology Group, YVR. He adds, “With this high-precision data at our disposal, we can trigger real-time alerts whenever we approach or exceed predefined thresholds. This invaluable capability enables us to collaborate seamlessly with our stakeholders, ensuring that our travelers experience a smooth and stress-free journey through our airport.” Q-Track YVR currently uses insights to meet several operational and business imperatives, such as reducing check-in time With Quanergy’s 3D LiDAR sensor and advanced perception software solution, Q-Track, YVR can accurately identify, classify, and track people/objects for enhanced operational insights. YVR currently uses these insights to meet several operational and business imperatives, such as reducing check-in time and time spent passing through security, which ultimately sees an increase in customer happiness. streamline operations “We are pleased to have collaborated closely with the YVR team, resolving a multifaceted challenge encountered by many passenger terminals today,” said Adam Andres, Vice President of Global Sales at Quanergy. He adds, “The forward-thinking of the YVR Innovation and Technology Group, in embracing Quanergy’s field-tested and fully scalable Q-Track solution, led to the achievement of our project objectives. We take pride in our contribution, providing real-time actionable intelligence to enhance security, streamline operations, and elevate the overall passenger experience.”

Mitsubishi Electric Corporation announced that it has delivered the first unit of an air-surveillance radar system to the Philippine Air Force last month. The system, which was designed, manufactured and tested in Japan, was ordered by the Department of National Defense of the Republic of the Philippines in August 2020. first unit of air-surveillance radar system delivered Mitsubishi Electric continues to work on the remaining units for future delivery This is the first time a Japanese company has transferred finished defense equipment to a foreign government since the Japanese government established the Three Principles on Transfer of Defense Equipment and Technology in April 2014. Mitsubishi Electric continues to work on the remaining units for future delivery. Mitsubishi Electric contributes to Japan’s security In accordance with the government’s aforementioned Three Principles, Mitsubishi Electric is contributing to Japan’s security by working to strengthen deterrence through cooperation with the Japanese government, in order to meet needs for joint development, equipment transfer and participation in supply chains involving various governments and companies in other countries.

Mota-Engil, a multi-national with activities focused on the construction and management of infrastructures, responsible for the construction of the Canoas wastewater lifting station, selected WEG as the provider of a large package of electrical solutions for an important initiative to decontaminate the waters of the Bogotá River, in Colombia. Sustainable development When the project is completed, the pumping station will receive the wastewater from approximately 70% of the city, corresponding to the Fucha, Tintal, and Tunjuelo river basins, and the wastewater from the Municipality of Soacha, to be later pumped to the future Canoas Wastewater Treatment Plant, which will be one of the largest in Latin America. This great milestone will make it possible to return quality water to the Bogotá River and guarantee the sustainable development of the country. Safe distribution of energy Seventeen medium voltage switchgears were also supplied in addition to low voltage load centers One of the great challenges of this project is to guarantee the safe distribution of energy to the electrical systems and motors. For this, WEG has supplied a complete 115 kV substation that includes two 30 MVA/115/13.2 kV transformers, adding more efficiency and reliability to the plant. 17 medium voltage switchgears were also supplied in addition to low voltage load centers. For this project, WEG will also be supplying six three-phase induction motors and six medium voltage variable frequency drives. Each 4,300 kW motor, vertically mounted, will be coupled to its respective pump and will be responsible for pumping 6.4 cubic meters of wastewater per second to 51.6 meters height from the well, one of the most critical processes in the plant. Improvement of the quality of life This demonstrates the company's ability to develop integrated solutions that meet the most diverse applications. With participation in other important projects in the water and wastewater segment, in various processes such as potable water treatment plants, wastewater treatment, and distribution systems, WEG reinforces its experience in this segment by being selected for this important project, thus contributing to the improvement of the quality of life of the population and the environment.

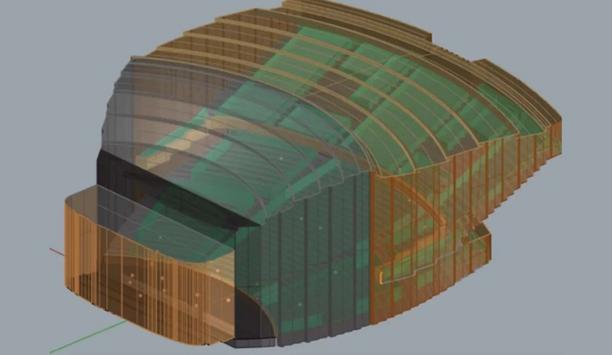

Siemens has developed a digital twin especially for large event spaces. The technology makes it possible to realistically reproduce and simulate very precisely a building’s acoustics and structure. The Sound of Science application will be used for the first time in the Großes Festspielhaus – the Large Festival Hall – at the Salzburg Festival. Sound of Science application Orchestral formations on the stage can also be tested and arranged in advance Sound of Science will enable event organizers to virtually explore how acoustics change in different spatial configurations – for example, how adding acoustic panels affects the listening experience – in order to select the optimal acoustic scenario. Orchestral formations on the stage can also be tested and arranged in advance – before a single note is heard in the real world. This approach saves money, resources and time. Siemens to use digital twins “With Sound of Science, we’re designing the future. Digital twins are not only transforming the everyday for many companies, but are also creating new opportunities for the cultural and creative industries,” said Prof. Dr. Stephan Frucht, Artistic Director of the Siemens Arts Program. Dr. Stephan Frucht adds, “In the future, we’ll be able to plan stage productions better and even simulate them acoustically in advance. We’re delighted to have the Salzburg Festival at our side as a long-standing partner, who recognizes the opportunities such innovations offer.” Sound of Science app for select partners Siemens will make the Sound of Science app available to selected partners from the cultural world free of charge as a demonstration application. There are currently no plans to market the application. Its simulation solutions, however, may be purchased. The Salzburg Festival’s Großes Festspielhaus is the first and only large event space to date in which Sound of Science is available. However, Siemens is planning to digitally simulate further spaces – including concert halls in Germany and England. At the Salzburg Festival, audiences will have an opportunity – unique for the time being – to use VR glasses to experience the application at the festival’s opening on July 20. Siemens and the Salzburg Festival “Siemens and the Salzburg Festival share a common passion for excellence and innovation. And we’re delighted to partake in this pioneering technological development and innovation as part of our long-standing close and trust-based partnership,” said Dr. Kristina Hammer, President of the Salzburg Festival. Dr. Kristina Hammer adds, “We’re excited to see what diverse applications will stem from Sound of Science in the future.” Siemens Simcenter’s simulation solutions The technologies used are part of the simulation solutions from Siemens Simcenter The technologies used are part of the simulation solutions from Siemens Simcenter, which has been part of the company’s core business for over 15 years. The technology is mostly used in industry – for example, for the acoustic optimization of vehicle interiors or for protection against street noise. For Sound of Science, Simcenter uses a combination of impulse response measurements and ray tracing for the 3D modeling of each event space. These methods can measure the echo and reverberation of a sound and simulate how sound waves propagate in a room. Depending on the material, reflections of sound waves behave differently. Those that bounce off a concrete wall react differently from those that hit a carpet or reach the ear directly. As a result, the simulation can reproduce the individual sound signature of each event space – in other words, its acoustic DNA. Siemens Festival Nights Siemens has been working closely with the Salzburg Festival for around 30 years. Since 1999, the company has also been the festival’s main sponsor. Since 2002, the Siemens Festival Nights have been held on Kapitelplatz square during the Salzburg Festival. Since its beginning, this open-air event has provided more than one million visitors with the opportunity to experience previous and current festival productions on an LED screen free of charge. In addition, some of the Salzburg Festival’s venues are equipped with Siemens technology from the areas of building automation, security and acoustics.

RO Capital Partners (“ROCP”), the RO Group’s venture capital arm, announces that its portfolio company, measurable.energy, has installed its smart power sockets in the office of PKF Francis Clark in Bristol. PKF Francis Clark is an award-winning firm of chartered accountants and business advisers. measurable.energy is a UK tech company that designs and manufactures smart, machine-learning-enabled power sockets that will reduce the energy costs of PKF Francis Clark’s Bristol office by more than 20%. PKF Francis Clark is located at 90 Victoria Street in that city, an office building comprising 24,377 sq. ft. of high-quality office accommodation across four storeys. Small Power energy use Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type measurable.energy’s solution eliminates ‘Small Power’ waste, which is energy not required by devices that are plugged in or directly wired; such as printers, AV equipment, chilled and hot water taps, monitors, and heaters, and which are often left fully on or in standby mode overnight. Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type of ‘Small Power’ energy use. Edward Rowlandson, Group Managing Director, the RO, said: "We are very pleased to have installed measurable.energy’s technology in our flagship Bristol property for a key tenant, PKF Francis Clark. We acquired 90 Victoria Street in Bristol in April 2023, and ROCP’s investment into Reading-based measurable.energy was also made early in 2023." PKF Francis Clark’s values Rowlandson added: “That investment was driven by the need to reduce energy, and we are delighted that PKF Francis Clark’s values align with our own, and that of measurable.energy. We look forward to seeing their simple solution for office occupiers who are under pressure to take action, cut energy costs, and reduce emissions installed in more properties around the country, as the business looks to scale.” CEO and Co-Founder of measurable.energy, Dan Williams said: “My electricity-saving message to companies is to not be fooled by the small size of certain devices. A very high percentage of an office occupier’s electricity bill hides in the shadows, among small gadgets and forgotten chargers." Power usage patterns Williams added:"This silent power drain adds up faster than tenants think, and without ever realizing it. Powered by machine learning, our plug sockets will automatically identify and eliminate ‘Small Power’ waste for PKF Francis Clark, turning every appliance in their Bristol office into a cost-saving superhero.” Jim Solomon, Regional Facilities Manager at PKF Francis Clark concluded: “Since deploying measurable. energy's AI-powered sockets, we have not only reduced our office's energy consumption of the devices using the sockets by 38%, but have also gained invaluable insights into our power usage patterns. This technology has been instrumental in our efforts to operate more sustainably and efficiently.”

Fluence Energy, Inc., a global provider of energy storage products, services, and optimization software for renewables and storage, announces that the company has been selected by Origin Energy Limited (Origin) to deliver a 300 MW / 650 MWh battery at the Mortlake Power Station in southwest Victoria. The project will use Fluence’s Gridstack™ energy storage product with a 15-year service agreement contributing to Origin’s strategy to accelerate renewable energy and energy storage in its portfolio. The system will also utilize Fluence’s AI-powered asset performance management (APM) software, Nispera™, to optimize the battery’s operational performance. Energy storage projects The system will capture excess power during periods of high renewable generation “We are honored to be selected by Origin to deliver this grid-forming battery-based energy storage system and deploy our ecosystem of solutions,” said Fluence President and Chief Executive Officer, Julian Nebreda. Julian Nebreda adds, “Australia is an important market for Fluence. Our local team is now delivering over 1 GW energy storage projects within Australia to enhance grid stability and enable the country’s clean energy transition.” Energy storage system to be commissioned in late 2026 The site preparation and civil works of the Mortlake Battery are expected to commence following a period of detailed design and procurement activity. The energy storage system is anticipated to be commissioned in late 2026. Located in Victoria’s South West Renewable Energy Zone, this energy storage system will provide system strength to the grid. The system will capture excess power during periods of high renewable generation and discharge to meet peak demand.

Quanergy Solutions, Inc., a provider of 3D LiDAR (Light Detection and Ranging) security solutions, was chosen by Vancouver International Airport (YVR) to analyze footfall to support the passenger journey with the ultimate goal of enhancing operational efficiencies. Quanergy’s technology is delivering accurate data-driven insights for YVR’s Domestic Check-in and Security Screening facilities. Real-time insights “Through the implementation of Quanergy’s solutions, we have harnessed the power of real-time insights, gaining a deep understanding of passenger volumes and the associated wait times at different stages of their journey through the terminal,” said Jason Williams, Manager of Innovation & Technology Group, YVR. He adds, “With this high-precision data at our disposal, we can trigger real-time alerts whenever we approach or exceed predefined thresholds. This invaluable capability enables us to collaborate seamlessly with our stakeholders, ensuring that our travelers experience a smooth and stress-free journey through our airport.” Q-Track YVR currently uses insights to meet several operational and business imperatives, such as reducing check-in time With Quanergy’s 3D LiDAR sensor and advanced perception software solution, Q-Track, YVR can accurately identify, classify, and track people/objects for enhanced operational insights. YVR currently uses these insights to meet several operational and business imperatives, such as reducing check-in time and time spent passing through security, which ultimately sees an increase in customer happiness. streamline operations “We are pleased to have collaborated closely with the YVR team, resolving a multifaceted challenge encountered by many passenger terminals today,” said Adam Andres, Vice President of Global Sales at Quanergy. He adds, “The forward-thinking of the YVR Innovation and Technology Group, in embracing Quanergy’s field-tested and fully scalable Q-Track solution, led to the achievement of our project objectives. We take pride in our contribution, providing real-time actionable intelligence to enhance security, streamline operations, and elevate the overall passenger experience.”

Mitsubishi Electric Corporation announced that it has delivered the first unit of an air-surveillance radar system to the Philippine Air Force last month. The system, which was designed, manufactured and tested in Japan, was ordered by the Department of National Defense of the Republic of the Philippines in August 2020. first unit of air-surveillance radar system delivered Mitsubishi Electric continues to work on the remaining units for future delivery This is the first time a Japanese company has transferred finished defense equipment to a foreign government since the Japanese government established the Three Principles on Transfer of Defense Equipment and Technology in April 2014. Mitsubishi Electric continues to work on the remaining units for future delivery. Mitsubishi Electric contributes to Japan’s security In accordance with the government’s aforementioned Three Principles, Mitsubishi Electric is contributing to Japan’s security by working to strengthen deterrence through cooperation with the Japanese government, in order to meet needs for joint development, equipment transfer and participation in supply chains involving various governments and companies in other countries.

Mota-Engil, a multi-national with activities focused on the construction and management of infrastructures, responsible for the construction of the Canoas wastewater lifting station, selected WEG as the provider of a large package of electrical solutions for an important initiative to decontaminate the waters of the Bogotá River, in Colombia. Sustainable development When the project is completed, the pumping station will receive the wastewater from approximately 70% of the city, corresponding to the Fucha, Tintal, and Tunjuelo river basins, and the wastewater from the Municipality of Soacha, to be later pumped to the future Canoas Wastewater Treatment Plant, which will be one of the largest in Latin America. This great milestone will make it possible to return quality water to the Bogotá River and guarantee the sustainable development of the country. Safe distribution of energy Seventeen medium voltage switchgears were also supplied in addition to low voltage load centers One of the great challenges of this project is to guarantee the safe distribution of energy to the electrical systems and motors. For this, WEG has supplied a complete 115 kV substation that includes two 30 MVA/115/13.2 kV transformers, adding more efficiency and reliability to the plant. 17 medium voltage switchgears were also supplied in addition to low voltage load centers. For this project, WEG will also be supplying six three-phase induction motors and six medium voltage variable frequency drives. Each 4,300 kW motor, vertically mounted, will be coupled to its respective pump and will be responsible for pumping 6.4 cubic meters of wastewater per second to 51.6 meters height from the well, one of the most critical processes in the plant. Improvement of the quality of life This demonstrates the company's ability to develop integrated solutions that meet the most diverse applications. With participation in other important projects in the water and wastewater segment, in various processes such as potable water treatment plants, wastewater treatment, and distribution systems, WEG reinforces its experience in this segment by being selected for this important project, thus contributing to the improvement of the quality of life of the population and the environment.

Siemens has developed a digital twin especially for large event spaces. The technology makes it possible to realistically reproduce and simulate very precisely a building’s acoustics and structure. The Sound of Science application will be used for the first time in the Großes Festspielhaus – the Large Festival Hall – at the Salzburg Festival. Sound of Science application Orchestral formations on the stage can also be tested and arranged in advance Sound of Science will enable event organizers to virtually explore how acoustics change in different spatial configurations – for example, how adding acoustic panels affects the listening experience – in order to select the optimal acoustic scenario. Orchestral formations on the stage can also be tested and arranged in advance – before a single note is heard in the real world. This approach saves money, resources and time. Siemens to use digital twins “With Sound of Science, we’re designing the future. Digital twins are not only transforming the everyday for many companies, but are also creating new opportunities for the cultural and creative industries,” said Prof. Dr. Stephan Frucht, Artistic Director of the Siemens Arts Program. Dr. Stephan Frucht adds, “In the future, we’ll be able to plan stage productions better and even simulate them acoustically in advance. We’re delighted to have the Salzburg Festival at our side as a long-standing partner, who recognizes the opportunities such innovations offer.” Sound of Science app for select partners Siemens will make the Sound of Science app available to selected partners from the cultural world free of charge as a demonstration application. There are currently no plans to market the application. Its simulation solutions, however, may be purchased. The Salzburg Festival’s Großes Festspielhaus is the first and only large event space to date in which Sound of Science is available. However, Siemens is planning to digitally simulate further spaces – including concert halls in Germany and England. At the Salzburg Festival, audiences will have an opportunity – unique for the time being – to use VR glasses to experience the application at the festival’s opening on July 20. Siemens and the Salzburg Festival “Siemens and the Salzburg Festival share a common passion for excellence and innovation. And we’re delighted to partake in this pioneering technological development and innovation as part of our long-standing close and trust-based partnership,” said Dr. Kristina Hammer, President of the Salzburg Festival. Dr. Kristina Hammer adds, “We’re excited to see what diverse applications will stem from Sound of Science in the future.” Siemens Simcenter’s simulation solutions The technologies used are part of the simulation solutions from Siemens Simcenter The technologies used are part of the simulation solutions from Siemens Simcenter, which has been part of the company’s core business for over 15 years. The technology is mostly used in industry – for example, for the acoustic optimization of vehicle interiors or for protection against street noise. For Sound of Science, Simcenter uses a combination of impulse response measurements and ray tracing for the 3D modeling of each event space. These methods can measure the echo and reverberation of a sound and simulate how sound waves propagate in a room. Depending on the material, reflections of sound waves behave differently. Those that bounce off a concrete wall react differently from those that hit a carpet or reach the ear directly. As a result, the simulation can reproduce the individual sound signature of each event space – in other words, its acoustic DNA. Siemens Festival Nights Siemens has been working closely with the Salzburg Festival for around 30 years. Since 1999, the company has also been the festival’s main sponsor. Since 2002, the Siemens Festival Nights have been held on Kapitelplatz square during the Salzburg Festival. Since its beginning, this open-air event has provided more than one million visitors with the opportunity to experience previous and current festival productions on an LED screen free of charge. In addition, some of the Salzburg Festival’s venues are equipped with Siemens technology from the areas of building automation, security and acoustics.

RO Capital Partners (“ROCP”), the RO Group’s venture capital arm, announces that its portfolio company, measurable.energy, has installed its smart power sockets in the office of PKF Francis Clark in Bristol. PKF Francis Clark is an award-winning firm of chartered accountants and business advisers. measurable.energy is a UK tech company that designs and manufactures smart, machine-learning-enabled power sockets that will reduce the energy costs of PKF Francis Clark’s Bristol office by more than 20%. PKF Francis Clark is located at 90 Victoria Street in that city, an office building comprising 24,377 sq. ft. of high-quality office accommodation across four storeys. Small Power energy use Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type measurable.energy’s solution eliminates ‘Small Power’ waste, which is energy not required by devices that are plugged in or directly wired; such as printers, AV equipment, chilled and hot water taps, monitors, and heaters, and which are often left fully on or in standby mode overnight. Up to 40% of total electricity usage in most commercial office buildings can be attributed to this type of ‘Small Power’ energy use. Edward Rowlandson, Group Managing Director, the RO, said: "We are very pleased to have installed measurable.energy’s technology in our flagship Bristol property for a key tenant, PKF Francis Clark. We acquired 90 Victoria Street in Bristol in April 2023, and ROCP’s investment into Reading-based measurable.energy was also made early in 2023." PKF Francis Clark’s values Rowlandson added: “That investment was driven by the need to reduce energy, and we are delighted that PKF Francis Clark’s values align with our own, and that of measurable.energy. We look forward to seeing their simple solution for office occupiers who are under pressure to take action, cut energy costs, and reduce emissions installed in more properties around the country, as the business looks to scale.” CEO and Co-Founder of measurable.energy, Dan Williams said: “My electricity-saving message to companies is to not be fooled by the small size of certain devices. A very high percentage of an office occupier’s electricity bill hides in the shadows, among small gadgets and forgotten chargers." Power usage patterns Williams added:"This silent power drain adds up faster than tenants think, and without ever realizing it. Powered by machine learning, our plug sockets will automatically identify and eliminate ‘Small Power’ waste for PKF Francis Clark, turning every appliance in their Bristol office into a cost-saving superhero.” Jim Solomon, Regional Facilities Manager at PKF Francis Clark concluded: “Since deploying measurable. energy's AI-powered sockets, we have not only reduced our office's energy consumption of the devices using the sockets by 38%, but have also gained invaluable insights into our power usage patterns. This technology has been instrumental in our efforts to operate more sustainably and efficiently.”

Fluence Energy, Inc., a global provider of energy storage products, services, and optimization software for renewables and storage, announces that the company has been selected by Origin Energy Limited (Origin) to deliver a 300 MW / 650 MWh battery at the Mortlake Power Station in southwest Victoria. The project will use Fluence’s Gridstack™ energy storage product with a 15-year service agreement contributing to Origin’s strategy to accelerate renewable energy and energy storage in its portfolio. The system will also utilize Fluence’s AI-powered asset performance management (APM) software, Nispera™, to optimize the battery’s operational performance. Energy storage projects The system will capture excess power during periods of high renewable generation “We are honored to be selected by Origin to deliver this grid-forming battery-based energy storage system and deploy our ecosystem of solutions,” said Fluence President and Chief Executive Officer, Julian Nebreda. Julian Nebreda adds, “Australia is an important market for Fluence. Our local team is now delivering over 1 GW energy storage projects within Australia to enhance grid stability and enable the country’s clean energy transition.” Energy storage system to be commissioned in late 2026 The site preparation and civil works of the Mortlake Battery are expected to commence following a period of detailed design and procurement activity. The energy storage system is anticipated to be commissioned in late 2026. Located in Victoria’s South West Renewable Energy Zone, this energy storage system will provide system strength to the grid. The system will capture excess power during periods of high renewable generation and discharge to meet peak demand.