5G

FPT Industrial, the Iveco Group brand dedicated to the design, production, and sale of powertrains and solutions for on- and off-road vehicles, as well as marine and power generation applications, will be heading to Dubai to exhibit at Middle East Energy, one of the most reputable and long-established events in the energy industry, being held from April 7 to 9. The brand will be present alongside its distributor network at Booth S2.C40, showcasing a selection of its offerings for the power gene...

Delta, a global pioneer in power management and smart green solutions, highlighted at Hannover Messe 2025 a versatile set of AI-driven smart manufacturing, energy infrastructure, and data centre solutions. These include, the award-winning D-Bot series cobots, featuring advanced cognitive capabilities and integration with NVIDIA Omniverse to develop next-generation digital twins; and DeltaGrid®, the AI-enabled energy management platform to optimize efficiency in the energy infrastructure sup...

Luxi Island microgrid system, which was designed, supplied, commissioned and delivered by NR, has been successfully put into operation. The system effectively solved the black start problem of 10kV feeder level microgrid with impulsive load, and has won high recognition from users with an advanced and intelligent control strategy, a stable and reliable microgrid system. Power supply of Luxi Island The power supply of Luxi Island was transmitted remotely by submarine cables Luxi Island is loc...

Delta, a pioneer in power management and a provider of IoT-based smart green solutions, announced the launch of its next-generation DC Wallbox 50kW EV charger. Designed to meet the demands of public and commercial charging applications, the upgraded model delivers advanced functionality and an optimized user-centric experience, ensuring seamless and efficient charging for both operators and electric vehicle (EV) drivers. EV charging infrastructure "The next-generation DC Wallbox 50kW exemplif...

Lanner Electronics, a pioneer in network computing appliances and industrial AI computers, will officially unveil its latest innovation, the EAI-I233 and EAI-I251 industrial-grade Edge AI computers, at NVIDIA GTC 2025. Powered by the NVIDIA® Jetson AGX Orin™ system on module (SOM), these advanced platforms are designed to deliver low-latency AI inferencing capabilities at the edge for industries including retail, manufacturing, transportation, and smart city. EAI-I233: AI inference s...

Aldercote, the pioneering UK manufacturer of vehicle-mounted access platforms, has appointed a new sales executive to meet demand for the company’s innovative products, which are supplied to firms across the UK and Europe. Mark Tooley joins the team with almost a decade’s experience in the industry and will be working with current and prospective customers to help make them aware of Aldercote’s range of products and the expert engineering and diagnostic support services it off...

News

Siemens is presenting its new developments in industrial automation and digitalization for the intralogistics industry at this year's Logimat. Faced with global challenges like labor shortages, growing sustainability requirements, and demographic change, the technology company is introducing innovative automation and digitalization solutions that increase efficiency, adaptability, and sustainability in intralogistics. Siemens Xcelerator ecosystem Siemens shows in a highlight showcase how the mix of software-defined and data-driven With Simatic Robot Pick AI Pro, an industrial vision AI for the development of AI-supported picking robots, Siemens demonstrates in a highlight showcase how the combination of software-defined and data-driven automation creates more adaptability and flexibility in automation solutions in order to overcome the challenges and complexity of today's intralogistics and to offer future-proof solutions. The Siemens Xcelerator ecosystem plays a central role by promoting innovation and integration across platform boundaries, which is accelerating the transition to a Digital Enterprise. Automation for advanced robotic solutions A blueprint for software-defined automation for advanced robotic solutions for robot-based picking of small parts in the intralogistics industry The centerpiece of the showcase at the Siemens booth is Simatic Robot Pick AI Pro, a pre-trained deep-learning vision software from Siemens that enables model-free 3D robot picking of unknown objects with individually adaptable vacuum multi-grippers. Simatic Robot Pick AI Pro The software reliably delivers gripping poses for a wide variety of inventory items in milliseconds The software reliably delivers gripping poses (6-DoF) for a wide variety of inventory items in milliseconds, regardless of their shape, size, or packaging. This means that Simatic Robot Pick AI Pro will facilitate the development of cost-effective, autonomous, and scalable robot solutions for single-piece order picking for sectors like e-commerce. It also addresses the labor shortage associated with monotonous picking tasks. Siemens Industrial Operations X portfolios Simatic Robot Pick AI Pro is a solution of Siemens Industrial Operations X portfolios, which is part of Siemens Xcelerator. Siemens Industrial Operations X combines software-defined automation and data-driven solutions within industrial ecosystems aiming to make systems more adaptive. An essential component of software-defined automation is Simatic AX, a modern development environment that increases efficiency in the creation and management of both physical and virtual controls. Use of advanced technologies Use of advanced technologies like edge and cloud computing to optimize operational processes Virtual PLCs (programmable logic controllers) are also being used to provide greater flexibility and scalability in deploying control systems as software containers based on industrial edge management. Industrial Operations X integrates these technologies and enables a seamless collaboration between different systems and the use of advanced technologies like edge and cloud computing to optimize and continuously improve operational processes. With this, machine builders can develop flexible and scalable robot order-picking systems that can be adapted to meet specific requirements. Robots with Siemens AI vision software Robots with Siemens AI vision software can autonomously identify and handle a variety of unknown objects, ensuring increased flexibility and adaptability in dynamic environments. There is also a seamless integration with TIA, which ensures a continuous data flow from the robot order-picking cell to the entire operational process. Development of new solutions and technologies Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers Siemens Xcelerator offers an open ecosystem for collaboration and innovation within a network of certified partners, such as Zivid for industrial 3D cameras or Piab for vacuum tools, to support the development of new solutions and technologies. At the exhibition, Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers in code generation and fault diagnosis and facilitates the engineering of complex automation systems. Siemens Industrial Copilot for engineering complex machines With the Siemens Industrial Copilot for TIA Portal Engineering, Siemens presents the first generative AI assistant for industrial engineering. Thanks to its seamless integration into the TIA Portal, the AI assistant simplifies and accelerates development processes and significantly minimizes error sources. It also allows less experienced professionals to effectively apply their knowledge and skills.

The surge in demand for Category 3 Control fire performance cables used in critical situations can only help to meet safety compliance requirements, says pioneering cable supplier AEI Cables. The systems powered by these cables – including smoke and heat extraction systems – assist fire services in firefighting and a safe evacuation in the case of life safety. Selection and installation of cables AEI Cables has been highlighting the importance of following the technical guidance for the selection and installation of cables for Category 3 Control fire performance cables under the revised British Standard BS8519: 2020 Code of Practice. These cables reduce harmful smoke, toxic gases and flame spread in the event of a real fire. Stuart Dover, General Manager of AEI Cables, said: "We are seeing quite an increase in demand for Category 3 Control cables and perhaps the information to use these cables for a specific safety reason is getting through to the supply chain." Guidance for Category 3 Control fire performance The guidance for Category 3 Control fire cables applies to evacuation alarms for the disabled in care homes Stuart Dover adds: "There can be no compromise when it comes to the selection of cables for these critical applications. We offer our comprehensive range of Category 3 Control backed up with our technical support and guidance for these specific uses." The guidance for Category 3 Control fire performance cables applies to evacuation alarms for the disabled in care homes, emergency voice communications systems and voice alarm systems in relevant buildings including tall buildings, office spaces, hospitals, shopping malls and stadia. AEI Cables’ products AEI Cables’ Firetec Enhanced cabling has been approved and certified by LPCB to BS8519 (Annex B), Category 3 Control in addition to Category 2 Control. The BS Code of Practice under BS8519 contains six categories of cables, three for power cables and three for control cables each covering survival times of 30, 60 or 120 minutes. All AEI Cables’ products are supplied with approvals from independent bodies including BASEC and LPCB. It also holds approvals from organizations, including Lloyds, the MoD, Network Rail and LUL and works to international standards around the world.

Siemens Smart Infrastructure and DOMO Chemicals, a provider of sustainable polyamide solutions, announces a significant milestone in their joint effort to promote sustainable practices in the electrical industry. DOMO Chemicals has successfully developed and validated a new, high-performance TECHNYL® 4EARTH® polyamide 6 (PA6) material to be used for Siemens applications, which incorporates recycled content and advanced flame-retardant technology. Commercial electrical installations Siemens will be using this material for electrical safety products for the first time. This groundbreaking TECHNYL® 4EARTH® material, specially developed by DOMO Chemicals, will enable Siemens to produce most of the covers and housings of the Siemens SENTRON 5SV3 residual current circuit breakers (RCCB), type A/AC, while offering the same performance and quality as conventional materials, which is a prerequisite for a safety product. RCCBs enhance electrical safety by quickly disconnecting power when they detect a current imbalance, preventing electric shocks and fires. They are essential in both residential and commercial electrical installations. Reducing the environmental impact The material significantly reduces the environmental impact of the manufacturing process Composed of 50 percent recycled content, including chemically recycled PA6 from various post-industrial and post-consumer sources such as fibers and textile filaments, as well as glass reinforcement, the material significantly reduces the environmental impact of the manufacturing process without compromising performance or quality. “We want to lead the industry with smart and sustainable technology,” said Andreas Matthé, CEO of Electrical Products at Siemens Smart Infrastructure. “It’s our ‘new normal’ to deploy as much sustainable material as possible for each new product to support our customers in achieving both optimized operations and their environmental goals. We are delighted to promote circularity and responsible use of resources in the electrical and electronics industry together with our partner DOMO Chemicals.” Standardized accessory system The SENTRON 5SV3 RCCBs, type A/AC, meet the criteria of the recently introduced Siemens EcoTech label. Besides using sustainable materials, the SENTRON RCCBs are designed to exceed the standard lifetime expectations set by IEC 61008-1. The SENTRON RCCBs are designed to exceed the standard lifetime expectations set by IEC 61008-1 With an impressive 10,000 operating cycles, these devices offer superior mechanical and electrical life, ensuring reliable performance and longevity. With SENTRON 5SV RCCBs, type A/AC, functionality of existing applications can be enhanced effortlessly. The standardized accessory system allows for easy hardware upgrades, including auxiliary switches, undervoltage releases, and more. This unified system of function extensions ensures that machines and switchboards remain productive and cost-effective for longer periods. Ensuring optimal performance TECHNYL® 4EARTH® C 52G1 V25 CR GY 2747 is used for most parts of the covers and housings of these RCCBs, which are produced in high quantities. The material is also UL certified, guaranteeing its quality and safety standards. The solution uses a phosphorous and halogen-free flame-retardant system. The PA6 compound offers excellent molding and electrical properties, ensuring optimal performance in demanding applications. The material can be easily customized to match specific color requirements, in this case, light grey. Environmentally friendly materials “At DOMO Chemicals, our ambition is to support our customers in achieving a lower carbon footprint without compromising performance. We are thrilled to partner with Siemens to deliver innovative and sustainable solutions that meet the growing demand for environmentally friendly materials,” said Juha Jokinen, Chief Commercial Officer Engineered Materials at DOMO Chemicals. “With our TECHNYL®4EARTH®, we combine high performance with various CO2 reduction targets. By leveraging our expertise in polyamide technology alongside Siemens’ strong sustainability focus, we aim to make a positive impact on the electrical industry, a dynamic and rapidly growing market.” Environmental impact reduction DOMO offers the broadest portfolio of sustainable polymers available on the market DOMO offers the broadest portfolio of sustainable polymers available on the market. Its offering includes mechanically and chemically recycled solutions as well as mass balance certified options. These alternatives come with different levels of performance and environmental impact reduction and are offered based on the end customer's application needs. Leveraging its extensive experience in flame-retardant and sustainable solutions, DOMO now provides unique sustainable alternatives to the E&E market, which combine minimized CO2 impact, a substantial amount of recycled content, the ability to be colored, and laser markability, all achieved through various flame-retardant technologies. Safety remains paramount, as evidenced by the material’s UL certification, which applies to both mechanical and chemical recycled alternatives. Demand for sustainable solutions DOMO Chemicals and Siemens Smart Infrastructure are committed to expanding the availability of this sustainable material to meet the global demand for sustainable solutions in the electrical and electronics industry, in line with changing consumer behavior. DOMO Chemicals' advanced recycling technology, coupled with its strong supplier network, enables the company to offer a wide range of sustainable polyamide solutions. The successful development of this flame-retardant PA6 compound demonstrates the potential of depolymerization as a promising technology for creating high-performance, environmentally friendly materials, supported by leading solution providers such as Siemens Smart Infrastructure.

GlobalLogic Inc., a Hitachi Group Company and pioneer in Digital Engineering, announces that its 2021 RDK Hackathon submission—a Voice over IP (VoIP) solution—has been selected as the event’s winner. The new technology introduces a standardized approach for making and receiving phone calls through RDK-B home gateways. In the future, open-source developers can benefit from a reliable solution that speeds the deployment of such functions over broadband telecommunications links instead of mobile networks. Network equipment manufacturers Chosen from three finalists, GlobalLogic received the recognition from RDK Management, the open-source consortium managing the Reference Design Kit (RDK) software platform that standardizes core functions used in video, broadband, and IoT connected devices. Chosen from three finalists, GlobalLogic received the recognition from RDK Management “Major telecom operators and network equipment manufacturers continue to evolve their offerings to meet modern use cases and remain competitive. GlobalLogic has been helping these and other companies such as silicon manufacturers and independent vendors develop broadband software based on RDK-B and other software stacks,” said Eli Schwarzfuchs, Managing Director, Israel and France Operations, GlobalLogic. “We’re honored to receive this award from RDK and view it as a validation of the experience and skills we’ve developed over time in this space. We look forward to contributing that expertise to the open-source community to help drive rapid innovation across the industry.” Customer-premises equipment GlobalLogic’s VoIP solution integration leverages Asterisk software—an open-source framework for building communications applications—which the company plans to contribute for RDK-B (RDK for Broadband). It registers customer-premises equipment, specifically the gateway, on the internet session initiation protocol (SIP) server and enables key capabilities such as: Making SIP calls through VoIP gateway instead of mobile networks Making SIP calls between other SIP-connected equipment without requiring internet access Using a single SIP trunk for all end customers instead of dedicated per-customer channels Universal access to incoming calls via any phone These capabilities and others can reduce overall management costs while increasing usability. Developing novel digital solutions “GlobalLogic is a well-recognized digital engineering company known for designing and developing novel digital solutions,” said Jason Briggs, President and General Manager of RDK. “The company’s award-winning performance at the Hackathon is a true testament to their innovation and commitment to the RDK community.” GlobalLogic recognizes the engineers responsible for the innovative technology, specifically highlighting the skilled efforts of the Ukraine and Israel teams.

On May 11, 2022, Hunan 500kV Shuicheng substation successfully put into operation. The substation is the first 500kV intelligent substation in Hunan Province to realize the remote "one key sequence control" function. The implementation and application of remote "one key sequence control" enables the staff of Changsha EHV centralized control station to operate the 500 kV Shuicheng substation equipment more than 300km away only in front of the centralized control computer, greatly shortened the operation time and reducing the risk of human error. Unattended intelligent substation The 500 kV Shuicheng Substation is located in Chenzhou City and it’s a key project in Hunan Province. The substation is designed as an unattended intelligent substation. NR as the system integrator of the substation, provides a secondary overall solution for the whole station, including intelligent protection measurement and control device, network switch, synchronous phasor, protection information system etc, realizes advanced functions such as remote operation of protection relays, bay level interlocking, dispatching sequence control, remote browsing and so on. NR commissioned the whole system successfully, which wins highly praised by users. NR will continue to give full play to the technical advantages accumulated in the field of protection & control, and is committed to providing better products and solutions for the global market.

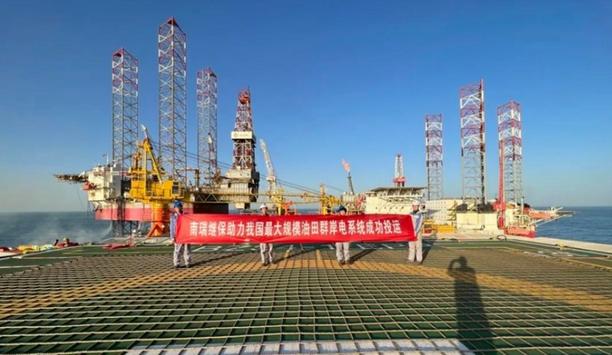

Recently China’s largest offshore oilfield group using land grid power supply application project - CNOOC Bozhong-Kenli Oilfield Group Shore Power Application Demonstration Project in the Bohai Sea region was successfully put into operation. Bozhong Kenli Oilfield shore power project includes onshore 220kV Haiguo switching station, offshore 220kV Haitai electric power platform, 220kV Haimin electric power platform, 220kV Hai'an electric power platform and 110kV Haixiang electric power platform. With the successful power transmission of each substation, it marks that the offshore and onshore backbone parts of Bozhong Kenli shore power project of Bohai Oilfield have been completed as scheduled. High energy consumption Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development as fuel for power generation, which not only has low efficiency and high energy consumption, and the stability is far lower than that of the large power grid. Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development After the shore power project is put into operation, compared with the peak year of power generation, the natural gas consumption will be reduced by 1.5 billion m3, the annual energy saving will be nearly 650,000 tons and other standard coals, which is equivalent to reducing carbon dioxide emissions by 1 million tons. Secondary system equipment The successful operation of the project will further change the previous "self-generation mode" of China's offshore oil fields. It is of great strategic significance for China to promote the adjustment of the national energy structure, achieve the goal of energy conservation and emission reduction, promote the green development of offshore oil and gas fields. As the supplier of the overall secondary system equipment of the shore power project, NR has provided a full set of core equipment such as integrated automation system, dispatching system, centralized control center, protection equipment, safety and stability control system, excitation inrush current suppressor, etc. for the four 220kV substations and one 110kV substation of the project. Special offshore environment NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology At the beginning of the project, NR went deep into the unique characteristics of the power grid structure and operation & maintenance of the Bozhong Kenli shore power project, and carried out in-depth relevant system research, simulation calculation and scheme design with CNOOC. As all systems of the offshore electric power platform are in the special offshore environment of high humidity and salinity, all complete sets of equipment provided by NR have passed the acceptance of the classification society of the classification society company, fully meeting the long-term, high requirements and high standards of operation in the offshore environment. NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology, excellent products and professional services, providing strong support for the power network construction of the world's largest offshore oilfield group. Ensuring energy security The smooth operation of Bozhong Kenli shore power project shows that as an enterprise in the field of power grid security and stability control, NR has made great support and positive contributions to the construction of major power projects in petrochemical industry. NR will continue to adhere to the corporate culture and work together to build on the past and open up the future, and protect the shore power access of CNOOC offshore oil and gas platforms from safe power supply to digital, unmanned and intelligent development, so as to contribute to promoting the high-quality development of the offshore oil industry and ensuring energy security.

Siemens is presenting its new developments in industrial automation and digitalization for the intralogistics industry at this year's Logimat. Faced with global challenges like labor shortages, growing sustainability requirements, and demographic change, the technology company is introducing innovative automation and digitalization solutions that increase efficiency, adaptability, and sustainability in intralogistics. Siemens Xcelerator ecosystem Siemens shows in a highlight showcase how the mix of software-defined and data-driven With Simatic Robot Pick AI Pro, an industrial vision AI for the development of AI-supported picking robots, Siemens demonstrates in a highlight showcase how the combination of software-defined and data-driven automation creates more adaptability and flexibility in automation solutions in order to overcome the challenges and complexity of today's intralogistics and to offer future-proof solutions. The Siemens Xcelerator ecosystem plays a central role by promoting innovation and integration across platform boundaries, which is accelerating the transition to a Digital Enterprise. Automation for advanced robotic solutions A blueprint for software-defined automation for advanced robotic solutions for robot-based picking of small parts in the intralogistics industry The centerpiece of the showcase at the Siemens booth is Simatic Robot Pick AI Pro, a pre-trained deep-learning vision software from Siemens that enables model-free 3D robot picking of unknown objects with individually adaptable vacuum multi-grippers. Simatic Robot Pick AI Pro The software reliably delivers gripping poses for a wide variety of inventory items in milliseconds The software reliably delivers gripping poses (6-DoF) for a wide variety of inventory items in milliseconds, regardless of their shape, size, or packaging. This means that Simatic Robot Pick AI Pro will facilitate the development of cost-effective, autonomous, and scalable robot solutions for single-piece order picking for sectors like e-commerce. It also addresses the labor shortage associated with monotonous picking tasks. Siemens Industrial Operations X portfolios Simatic Robot Pick AI Pro is a solution of Siemens Industrial Operations X portfolios, which is part of Siemens Xcelerator. Siemens Industrial Operations X combines software-defined automation and data-driven solutions within industrial ecosystems aiming to make systems more adaptive. An essential component of software-defined automation is Simatic AX, a modern development environment that increases efficiency in the creation and management of both physical and virtual controls. Use of advanced technologies Use of advanced technologies like edge and cloud computing to optimize operational processes Virtual PLCs (programmable logic controllers) are also being used to provide greater flexibility and scalability in deploying control systems as software containers based on industrial edge management. Industrial Operations X integrates these technologies and enables a seamless collaboration between different systems and the use of advanced technologies like edge and cloud computing to optimize and continuously improve operational processes. With this, machine builders can develop flexible and scalable robot order-picking systems that can be adapted to meet specific requirements. Robots with Siemens AI vision software Robots with Siemens AI vision software can autonomously identify and handle a variety of unknown objects, ensuring increased flexibility and adaptability in dynamic environments. There is also a seamless integration with TIA, which ensures a continuous data flow from the robot order-picking cell to the entire operational process. Development of new solutions and technologies Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers Siemens Xcelerator offers an open ecosystem for collaboration and innovation within a network of certified partners, such as Zivid for industrial 3D cameras or Piab for vacuum tools, to support the development of new solutions and technologies. At the exhibition, Siemens will also show exactly how the Siemens Industrial Copilot supports automation engineers in code generation and fault diagnosis and facilitates the engineering of complex automation systems. Siemens Industrial Copilot for engineering complex machines With the Siemens Industrial Copilot for TIA Portal Engineering, Siemens presents the first generative AI assistant for industrial engineering. Thanks to its seamless integration into the TIA Portal, the AI assistant simplifies and accelerates development processes and significantly minimizes error sources. It also allows less experienced professionals to effectively apply their knowledge and skills.

The surge in demand for Category 3 Control fire performance cables used in critical situations can only help to meet safety compliance requirements, says pioneering cable supplier AEI Cables. The systems powered by these cables – including smoke and heat extraction systems – assist fire services in firefighting and a safe evacuation in the case of life safety. Selection and installation of cables AEI Cables has been highlighting the importance of following the technical guidance for the selection and installation of cables for Category 3 Control fire performance cables under the revised British Standard BS8519: 2020 Code of Practice. These cables reduce harmful smoke, toxic gases and flame spread in the event of a real fire. Stuart Dover, General Manager of AEI Cables, said: "We are seeing quite an increase in demand for Category 3 Control cables and perhaps the information to use these cables for a specific safety reason is getting through to the supply chain." Guidance for Category 3 Control fire performance The guidance for Category 3 Control fire cables applies to evacuation alarms for the disabled in care homes Stuart Dover adds: "There can be no compromise when it comes to the selection of cables for these critical applications. We offer our comprehensive range of Category 3 Control backed up with our technical support and guidance for these specific uses." The guidance for Category 3 Control fire performance cables applies to evacuation alarms for the disabled in care homes, emergency voice communications systems and voice alarm systems in relevant buildings including tall buildings, office spaces, hospitals, shopping malls and stadia. AEI Cables’ products AEI Cables’ Firetec Enhanced cabling has been approved and certified by LPCB to BS8519 (Annex B), Category 3 Control in addition to Category 2 Control. The BS Code of Practice under BS8519 contains six categories of cables, three for power cables and three for control cables each covering survival times of 30, 60 or 120 minutes. All AEI Cables’ products are supplied with approvals from independent bodies including BASEC and LPCB. It also holds approvals from organizations, including Lloyds, the MoD, Network Rail and LUL and works to international standards around the world.

Siemens Smart Infrastructure and DOMO Chemicals, a provider of sustainable polyamide solutions, announces a significant milestone in their joint effort to promote sustainable practices in the electrical industry. DOMO Chemicals has successfully developed and validated a new, high-performance TECHNYL® 4EARTH® polyamide 6 (PA6) material to be used for Siemens applications, which incorporates recycled content and advanced flame-retardant technology. Commercial electrical installations Siemens will be using this material for electrical safety products for the first time. This groundbreaking TECHNYL® 4EARTH® material, specially developed by DOMO Chemicals, will enable Siemens to produce most of the covers and housings of the Siemens SENTRON 5SV3 residual current circuit breakers (RCCB), type A/AC, while offering the same performance and quality as conventional materials, which is a prerequisite for a safety product. RCCBs enhance electrical safety by quickly disconnecting power when they detect a current imbalance, preventing electric shocks and fires. They are essential in both residential and commercial electrical installations. Reducing the environmental impact The material significantly reduces the environmental impact of the manufacturing process Composed of 50 percent recycled content, including chemically recycled PA6 from various post-industrial and post-consumer sources such as fibers and textile filaments, as well as glass reinforcement, the material significantly reduces the environmental impact of the manufacturing process without compromising performance or quality. “We want to lead the industry with smart and sustainable technology,” said Andreas Matthé, CEO of Electrical Products at Siemens Smart Infrastructure. “It’s our ‘new normal’ to deploy as much sustainable material as possible for each new product to support our customers in achieving both optimized operations and their environmental goals. We are delighted to promote circularity and responsible use of resources in the electrical and electronics industry together with our partner DOMO Chemicals.” Standardized accessory system The SENTRON 5SV3 RCCBs, type A/AC, meet the criteria of the recently introduced Siemens EcoTech label. Besides using sustainable materials, the SENTRON RCCBs are designed to exceed the standard lifetime expectations set by IEC 61008-1. The SENTRON RCCBs are designed to exceed the standard lifetime expectations set by IEC 61008-1 With an impressive 10,000 operating cycles, these devices offer superior mechanical and electrical life, ensuring reliable performance and longevity. With SENTRON 5SV RCCBs, type A/AC, functionality of existing applications can be enhanced effortlessly. The standardized accessory system allows for easy hardware upgrades, including auxiliary switches, undervoltage releases, and more. This unified system of function extensions ensures that machines and switchboards remain productive and cost-effective for longer periods. Ensuring optimal performance TECHNYL® 4EARTH® C 52G1 V25 CR GY 2747 is used for most parts of the covers and housings of these RCCBs, which are produced in high quantities. The material is also UL certified, guaranteeing its quality and safety standards. The solution uses a phosphorous and halogen-free flame-retardant system. The PA6 compound offers excellent molding and electrical properties, ensuring optimal performance in demanding applications. The material can be easily customized to match specific color requirements, in this case, light grey. Environmentally friendly materials “At DOMO Chemicals, our ambition is to support our customers in achieving a lower carbon footprint without compromising performance. We are thrilled to partner with Siemens to deliver innovative and sustainable solutions that meet the growing demand for environmentally friendly materials,” said Juha Jokinen, Chief Commercial Officer Engineered Materials at DOMO Chemicals. “With our TECHNYL®4EARTH®, we combine high performance with various CO2 reduction targets. By leveraging our expertise in polyamide technology alongside Siemens’ strong sustainability focus, we aim to make a positive impact on the electrical industry, a dynamic and rapidly growing market.” Environmental impact reduction DOMO offers the broadest portfolio of sustainable polymers available on the market DOMO offers the broadest portfolio of sustainable polymers available on the market. Its offering includes mechanically and chemically recycled solutions as well as mass balance certified options. These alternatives come with different levels of performance and environmental impact reduction and are offered based on the end customer's application needs. Leveraging its extensive experience in flame-retardant and sustainable solutions, DOMO now provides unique sustainable alternatives to the E&E market, which combine minimized CO2 impact, a substantial amount of recycled content, the ability to be colored, and laser markability, all achieved through various flame-retardant technologies. Safety remains paramount, as evidenced by the material’s UL certification, which applies to both mechanical and chemical recycled alternatives. Demand for sustainable solutions DOMO Chemicals and Siemens Smart Infrastructure are committed to expanding the availability of this sustainable material to meet the global demand for sustainable solutions in the electrical and electronics industry, in line with changing consumer behavior. DOMO Chemicals' advanced recycling technology, coupled with its strong supplier network, enables the company to offer a wide range of sustainable polyamide solutions. The successful development of this flame-retardant PA6 compound demonstrates the potential of depolymerization as a promising technology for creating high-performance, environmentally friendly materials, supported by leading solution providers such as Siemens Smart Infrastructure.

GlobalLogic Inc., a Hitachi Group Company and pioneer in Digital Engineering, announces that its 2021 RDK Hackathon submission—a Voice over IP (VoIP) solution—has been selected as the event’s winner. The new technology introduces a standardized approach for making and receiving phone calls through RDK-B home gateways. In the future, open-source developers can benefit from a reliable solution that speeds the deployment of such functions over broadband telecommunications links instead of mobile networks. Network equipment manufacturers Chosen from three finalists, GlobalLogic received the recognition from RDK Management, the open-source consortium managing the Reference Design Kit (RDK) software platform that standardizes core functions used in video, broadband, and IoT connected devices. Chosen from three finalists, GlobalLogic received the recognition from RDK Management “Major telecom operators and network equipment manufacturers continue to evolve their offerings to meet modern use cases and remain competitive. GlobalLogic has been helping these and other companies such as silicon manufacturers and independent vendors develop broadband software based on RDK-B and other software stacks,” said Eli Schwarzfuchs, Managing Director, Israel and France Operations, GlobalLogic. “We’re honored to receive this award from RDK and view it as a validation of the experience and skills we’ve developed over time in this space. We look forward to contributing that expertise to the open-source community to help drive rapid innovation across the industry.” Customer-premises equipment GlobalLogic’s VoIP solution integration leverages Asterisk software—an open-source framework for building communications applications—which the company plans to contribute for RDK-B (RDK for Broadband). It registers customer-premises equipment, specifically the gateway, on the internet session initiation protocol (SIP) server and enables key capabilities such as: Making SIP calls through VoIP gateway instead of mobile networks Making SIP calls between other SIP-connected equipment without requiring internet access Using a single SIP trunk for all end customers instead of dedicated per-customer channels Universal access to incoming calls via any phone These capabilities and others can reduce overall management costs while increasing usability. Developing novel digital solutions “GlobalLogic is a well-recognized digital engineering company known for designing and developing novel digital solutions,” said Jason Briggs, President and General Manager of RDK. “The company’s award-winning performance at the Hackathon is a true testament to their innovation and commitment to the RDK community.” GlobalLogic recognizes the engineers responsible for the innovative technology, specifically highlighting the skilled efforts of the Ukraine and Israel teams.

On May 11, 2022, Hunan 500kV Shuicheng substation successfully put into operation. The substation is the first 500kV intelligent substation in Hunan Province to realize the remote "one key sequence control" function. The implementation and application of remote "one key sequence control" enables the staff of Changsha EHV centralized control station to operate the 500 kV Shuicheng substation equipment more than 300km away only in front of the centralized control computer, greatly shortened the operation time and reducing the risk of human error. Unattended intelligent substation The 500 kV Shuicheng Substation is located in Chenzhou City and it’s a key project in Hunan Province. The substation is designed as an unattended intelligent substation. NR as the system integrator of the substation, provides a secondary overall solution for the whole station, including intelligent protection measurement and control device, network switch, synchronous phasor, protection information system etc, realizes advanced functions such as remote operation of protection relays, bay level interlocking, dispatching sequence control, remote browsing and so on. NR commissioned the whole system successfully, which wins highly praised by users. NR will continue to give full play to the technical advantages accumulated in the field of protection & control, and is committed to providing better products and solutions for the global market.

Recently China’s largest offshore oilfield group using land grid power supply application project - CNOOC Bozhong-Kenli Oilfield Group Shore Power Application Demonstration Project in the Bohai Sea region was successfully put into operation. Bozhong Kenli Oilfield shore power project includes onshore 220kV Haiguo switching station, offshore 220kV Haitai electric power platform, 220kV Haimin electric power platform, 220kV Hai'an electric power platform and 110kV Haixiang electric power platform. With the successful power transmission of each substation, it marks that the offshore and onshore backbone parts of Bozhong Kenli shore power project of Bohai Oilfield have been completed as scheduled. High energy consumption Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development as fuel for power generation, which not only has low efficiency and high energy consumption, and the stability is far lower than that of the large power grid. Traditional offshore oil fields mainly use natural gas and crude oil associated with oil field development After the shore power project is put into operation, compared with the peak year of power generation, the natural gas consumption will be reduced by 1.5 billion m3, the annual energy saving will be nearly 650,000 tons and other standard coals, which is equivalent to reducing carbon dioxide emissions by 1 million tons. Secondary system equipment The successful operation of the project will further change the previous "self-generation mode" of China's offshore oil fields. It is of great strategic significance for China to promote the adjustment of the national energy structure, achieve the goal of energy conservation and emission reduction, promote the green development of offshore oil and gas fields. As the supplier of the overall secondary system equipment of the shore power project, NR has provided a full set of core equipment such as integrated automation system, dispatching system, centralized control center, protection equipment, safety and stability control system, excitation inrush current suppressor, etc. for the four 220kV substations and one 110kV substation of the project. Special offshore environment NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology At the beginning of the project, NR went deep into the unique characteristics of the power grid structure and operation & maintenance of the Bozhong Kenli shore power project, and carried out in-depth relevant system research, simulation calculation and scheme design with CNOOC. As all systems of the offshore electric power platform are in the special offshore environment of high humidity and salinity, all complete sets of equipment provided by NR have passed the acceptance of the classification society of the classification society company, fully meeting the long-term, high requirements and high standards of operation in the offshore environment. NR has assisted the smooth implementation of Bozhong Kenli shore power project with advanced technology, excellent products and professional services, providing strong support for the power network construction of the world's largest offshore oilfield group. Ensuring energy security The smooth operation of Bozhong Kenli shore power project shows that as an enterprise in the field of power grid security and stability control, NR has made great support and positive contributions to the construction of major power projects in petrochemical industry. NR will continue to adhere to the corporate culture and work together to build on the past and open up the future, and protect the shore power access of CNOOC offshore oil and gas platforms from safe power supply to digital, unmanned and intelligent development, so as to contribute to promoting the high-quality development of the offshore oil industry and ensuring energy security.

Expert Commentary

The promise of electric vehicles is closer to reality than ever before. New plans and investments at the federal level designate billions of dollars to move our country toward clean energy, including $2 million to help auto manufacturers retool facilities to increase EV production. Additionally, the Biden Administration has announced a goal to create 100% carbon-free electricity by 2035 and a net-zero carbon economy by 2050. Domestic EV marketplace The domestic EV marketplace has grown from 16,000 to more than 2 million vehicles in the last decade and is poised to expand at lightning speed over the next ten years. S&P Global mobility has predicted that by 2030, electric vehicles (EVs) will make up 40% of the U.S. market share of new vehicles on the road. This dramatic increase in EVs will require a nationwide network of charging stations to meet the demand from the current 140,000 to over 1.1 million. Charging stations It is a necessity that regulators lay the groundwork now for a reliable and secure charging networkThe expansion of charging stations will undoubtedly give zero-emissions drivers more confidence in their ability to refuel more conveniently. Still, it’s critical that confidence in infrastructure security also be prioritized alongside this growth. If not adequately protected and monitored, charging stations could serve as access points for cybercriminals, potentially leading to personal data leaks, attacks on vehicle systems, and even widespread blackouts. As EVs continue to gain momentum as realistic alternatives to CO-2 emitting vehicles, it is a necessity that developers and regulators lay the groundwork now for a reliable and secure charging network for the long term. EV Charging Infrastructure and the electric grid The nation’s electric grid generates and delivers electricity essential to everyday life. It’s made up of power plants and other sources of generated electricity, complete with transmission and distribution lines and infrastructure that delivers essential power. Grid connection An important aspect to remember about EV charging stations is that they connect to their relative electric grid. Simply put, the infrastructure for charging stations is comprised of devices that wait for another device to connect and communicate. However, it lacks a third-party firewall or other devices that can act as protection. Unfortunately, this results in vulnerability and means new doors for cybercriminals to walk through. Cybersecurity risks If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts Even before EV charging stations are factored in, the electric grid faces substantial cybersecurity risks from criminals, terrorists, hackers, and foreign governments every day. If the grid became compromised by a large-scale attack, it could lead to destructive and widespread blackouts that would undoubtedly affect EV charging stations and other essential institutions such as banks, hospitals, and gas stations. With the expansion of EV charging stations, the risks only grow. Now is the time to address threats and strategize before disaster strikes. Risks of connectivity emerge The world we live in has reached a level of being almost entirely connected at all times – security systems, appliances, health monitors, industrial sensors, and now, our vehicles. While the connectivity of vehicles has been incredibly beneficial to consumers and the automotive industry alike, the growth in the internet of things (IoT) has opened countless doorways for cybersecurity threats. Software flaws One young information technology security specialist reported finding flaws within a third-party software that a handful of leading EV manufacturers use. It gave him access to more than 25 EVs in at least 13 countries. The man, who stumbled on the findings in 2022, said he could remotely control some EV functions, including starting vehicles, unlocking windows and doors, disabling security systems, and turning on stereo systems and flashing headlights. The IT specialist said he could also tell if a person was in the vehicle. In a separate and concerning situation, a single compromised password led to a foreign-fronted cyberattack on a U.S.-based pipeline in 2021. It halted the fuel supply process on the east coast and cost the company $4.4 million in ransom money. Cyberattacks Thousands of charging stations are already in danger of being targeted by cybercriminals The point is that even massive and powerful companies can fall victim to cyberattacks. Even though cybersecurity is a critical issue for EV manufacturers, their systems are still vulnerable to hackers. Thousands of charging stations are already in danger of being targeted by cybercriminals, and as the number of stations grows, so too will the risk. The higher the number of entry points, the more opportunities hackers will see. If they can break into and gain access to even the most sophisticated EVs, it could be catastrophic. Ensuring security and reliability through proactivity Because charging stations are connected to the country’s primary grid, the entire infrastructure must be armed with the most aggressive security measures. The risks associated with modernized electric vehicles are not something that traditional automotive safety regulations and security standards properly cover. The complicated and rapid evolution of EVs is putting them at a heightened threat. When charging stations are connected to the electrical grid, it is imperative to ensure strong cybersecurity measures are in place to remain dependable and effective. Embedding cybersecurity technology We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection The best way to ensure the electric grid's safety is to build cybersecurity technology directly into the charging stations. We often see outside parties utilized to secure tech because of the frequent lack of necessary cyber protection. Unfortunately, the promising growth EVs and their charging stations bring to our environment also contributes to technology’s vulnerabilities, which can cause key security measures to be overlooked. There’s no getting around it: EV charging stations are highly vulnerable to hackers. Awareness and solutions As the growth continues, there is an acute need for heightened awareness and solutions for the weaknesses associated with these charging stations. These solutions should consider everything from the charging points and devices to operators of the energy distribution networks and infrastructure providers. We must aim to implement advanced cybersecurity measures that will keep safe drivers and all the data that EVs contain.

Case studies

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.

Jenkins sold a Jenkins Motor Test System to Oman, where temperatures can exceed 120ºF. While Jenkins Motor Test Systems are built tough and for industrial environments, this specific location required customizations to be the most effective in an extremely hot environment. Locations near large bodies of water or tropical environments can also cause problems as the humidity in the air will cause the copper wiring in the transformer to oxidize over time. Although Jenkins designs its equipment to operate for long periods, some applications for customer environments require specific customization. The Solution Jenkins engineers and winders worked together to develop a custom solution for this harsh climate, particularly paying close attention to temperature and water resistance. To customize the transformer for this environment, the Jenkins team made the following modifications: Doubling the spacing between winding layers to increase airflow. Encasing the transformer first in a high tolerance epoxy varnish, and then in a polyester over-dip that prevents the application from rust, dust, and harmful materials. Utilizing expanded metal at the base of the MTS enclosure, allows heat to escape, reducing the internal temperature. Installing temperature-sensitive cooling fans (set to 100ºF) atop the enclosure to prevent overheating. The Results Jenkins technicians checked insulation for 10,000 volts (resistance to ground), checked each voltage leg, and high voltage potential to ground, and ensured the taps were in the correct place. Voltage was confirmed to operate up to 20% above normal operation, ensuring maximum efficiency and longevity of the transformer. These modifications have resulted in prolonged use of the Jenkins Motor Test System in harsh environments and ultimately customer satisfaction.

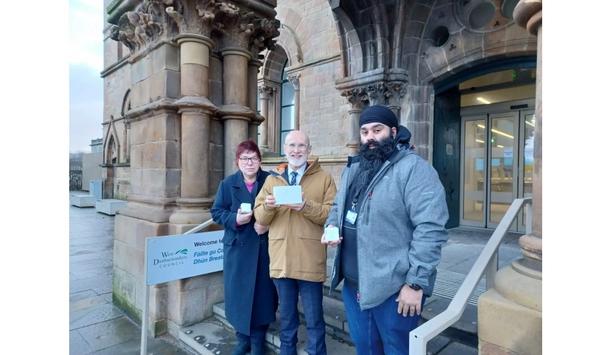

As part of their strategy to address damp and mold, West Dunbartonshire Council will deploy Aico’s HomeLINK Environmental Sensors across all their properties. The Council is one of Scotland’s major social housing landlords, currently owning and managing over 10,400 homes, and are focusing on increasing energy efficiency, tackling existing issues, such as damp and mold, as well as improving tenant safety, health and well-being. Ei1000G Gateway and Ei1025, Ei1020 Environmental Sensors The organization has taken the proactive approach to install the Ei1000G Gateway and Ei1025 and Ei1020 Environmental Sensors in each of their homes, making this Scotland’s largest scaled Internet of Things (IoT) roll out to date. By utilizing a multi-network sim card and RF interconnection, the sensors will be seamlessly retrofitted By utilizing a multi-network sim card and RF interconnection, the sensors will be seamlessly retrofitted into existing properties and can provide the council with a consistency on key air quality information, such as carbon dioxide, temperature, humidity, as well as insights on fire and CO activations. This will then lead to insights such as indoor air quality (IAQ) risk, damp and mold, excess heat, cold homes, potential fuel poverty, and void risk. HomeLINK App for Residents The HomeLINK App for Residents empowers individuals to take control of their home’s indoor environment. Tenants will receive alarm testing reminders and tailored recommendations. Councilor Gurpreet Singh Johal, Convener of Housing and Communities, said: “None of our tenants should be living in a home that is affected by damp or mold and these new sensors will allow us to access information on the fabric of each home easily so we can take action quickly to resolve. Not only that, we will have data to track the problem and help us identify what the best approach to resolve it will be.” Biggest roll out of this type of sensor in Scotland Councilor Gurpreet Singh Johal adds, “This is the biggest roll out of this type of sensor in Scotland and I am proud that West Dunbartonshire’s approach to dealing with damp and mold is not only leading the way, but addressing the problem in an efficient and proactive manner.” As Scotland’s social housing sector now rapidly adopts the use of IoT technologies" Gregor Morrison, Regional Specification Manager for the West of Scotland said “As Scotland’s social housing sector now rapidly adopts the use of IoT technologies to help not only increase the level of home life safety, but to improve resident health and well-being. This progressive approach from West Dunbartonshire Council to provide all homes with the opportunity for this technology is admirable.” Incorporation of the Environmental Sensors Gregor Morrison adds, “The incorporation of the Environmental Sensors will be pivotal in generating essential home health insights, as well as providing data for the tenant through the resident app, leading to healthier and more energy-efficient homes within the community.” He continues, “Growing up in and around the social housing sector in Yoker & Clydebank, I’m really looking forward to continuing the close working relationship with WDC, and seeing first-hand the difference the technology can make within the community.”

As part of a long-term modernization project at the Baltimore Washington International (BWI) Airport, Helios Electric was retained to perform design-assist, system integration, and on-site field engineering services. The project involved replacing an existing 7.5/10.5 MVA outdoor substation transformer and performing retrofit services at the corresponding medium-voltage switchgear lineups. The project also included enhancements to the electrical system protection since power reliability was deemed vital for airport operations. SEL-787 transformer protection relay A new SEL-787 transformer protection relay was installed to perform advanced transformer monitoring, controls, and system protection. New pilot control devices were installed on the corresponding switchgear lineups to indicate transformer faults, alarms, and mechanical conditions. Vacuum circuit breakers at the existing switchgear lineups were retained and modified to establish connectivity with the new substation transformer and the new transformer protection relay. transformer protection functions This installation approach yielded improved protection for the new transformer while limiting the scope, budget, duration, and power outages required to accomplish the necessary tasks. The improved transformer protection functions included the following: ANSI-87 – Current Differential Protection ANSI-87G – Restricted Earth Fault Protection ANSI-50/51 – Phase Overcurrent Protection (Backup) ANSI-50/51G – Ground Overcurrent Protection (Backup) ANSI-63 – Transformer Sudden Pressure ANSI-71 – Transformer Low Oil Level ANSI-49 – Transformer High Winding Temperature ANSI-26 – Transformer High Oil Temperature AC/DC control modifications To fulfill the customer’s desired requirements, the Helios Electric team investigated the internal circuitry of the switchgear lineups and ascertained the specific AC/DC control modifications required at the existing. Work performed under this project included the following: Examining and analyzing the components and sub-components of the existing switchgear lineups. Tracing the existing 35kV-class and 15kV-class vacuum circuit breakers to determine the existing field configuration. Developing modified equipment shop drawings for approval, construction, and as-built conditions. Programming and configuration of SEL-787 Transformer Protection Relay to establish system protection, controls, and integration with the facility’s Supervisory Control and Data Acquisition (SCADA) System. Installing and modifying existing 35kV-class and 15kV-class vacuum circuit breaker controls to accommodate the new substation transformer and transformer protection relay. Developing Operation & Maintenance (O&M) manuals for modified electrical equipment lineups. On-site electrical equipment training for airport maintenance personnel.

SoFi Stadium, a world-class venue, turned to industry major - Belden for a complete end-to-end cabling and connectivity solution. Belden’s cutting-edge technology supports the stadium’s data-heavy demands, including the one-of-a-kind, roof-suspended Oculus video board, Wi-Fi infrastructure, digital ticketing, and a DAS system. Belden’s solutions for SoFi Stadium When the stadium’s owners required a solution that delivered top-tier quality, performance, and reliability while reducing labor costs, they called Belden. Count on Arrow to deliver unparalleled excellence in the low-voltage industry. Arrow will equip with the competitive advantage needed for any customer, any configuration, and any budget. Copper Cables & Copper Solutions Discover the ultimate lineup of Belden Inc. category cables, tailored to suit every application imaginable! Discover the ultimate lineup of Belden Inc. category cables, tailored to suit every application imaginable! Many cables featured their signature patented Bonded-Pair design, guaranteeing unparalleled signal integrity. Plus, with DataTuff® Industrial category cables, rest assured the system remains resilient against the toughest environmental conditions. Category 6A Choose from an assortment of configurations including small diameter, snake, industrial, non-bonded, and their innovative patented Bonded-Pair technology. Elevating performance benchmarks, Belden's renowned 10GXS Cable stands as the gold standard in the industry. Category 6 Belden has a wide array of Category 6 performance options, featuring their top-of-the-line REVConnect 3600 System cable boasting premium performance and ample headroom. The REVConnect 2400 System cable, surpasses TIA-568-C.2 standards, all backed by Belden’s renowned quality. Category 5e Belden presents a range of Category 5e performance options, with their flagship 1200 Series cable delivering exceptional headroom, surpassing the TIA-568-C.2 Category 5e standard. Featuring Bonded-Pair technology, their 1200 Series ensures unparalleled robustness in installations. Patch Panel Belden’s commercial-grade panels are available in modular (empty) configurations Belden offers a comprehensive range of copper patch panels tailored to meet the demands of both commercial and industrial settings. Belden’s commercial-grade panels are available in modular (empty) configurations or pre-loaded with high-quality copper jacks designed for Category 6A, 6, and 5E network installations. Trunk Cable Optimized for data centers, enterprise networks, and any environment prioritizing swift installation, Trunk Cable Assemblies offer factory termination and rigorous testing, slashing installation time by up to 90%. Eliminating the need for termination, these assemblies come in diverse lengths, equipped with connectors tailored to specific application requirements. Patch Cord Enhancing both performance and physical durability, Belden’s Copper Patch Cords ensure optimal transmission quality for network channels. With superb return loss characteristics adaptable to any environment, Belden’s Copper Patch Cords come in modular, small-diameter, and traceable solutions to meet specific needs. Fiber Cable & Fiber Solutions Discover an array of high-quality indoor and outdoor cable solutions within Belden’s comprehensive product line, featuring both tight buffer and loose tube designs. Tailored for diverse industrial settings, their offerings include armored, burial, and ruggedized options. Crafted to meet various specifications, their product range encompasses OM1, OM3, OM4, OM5, and OS2 (Single Mode) configurations. Tight Buffer Fiber Cables Tight-Buffered Fiber Cables are perfectly tailored for enterprise environments Tight-Buffered Fiber Cables are perfectly tailored for enterprise environments, these cables stand out as a crowd favorite, ideal for intra-building backbones and both horizontal and vertical installations. Offering versatility like no other, they come in fiber counts ranging from two to an impressive 144, making them adaptable to any project scale. Whether indoors or outdoors, these cables are engineered to exceed expectations, boasting a design that ensures seamless performance in any environment. Loose Tube Cables Belden’s Loose Tube Cables offer the ultimate solution for all outdoor and indoor/outdoor fiber optic needs. Whether it’s for OSP, conduit, direct burial, aerial, or trunking applications, Belden’s cables offer unmatched versatility and performance. Choose from a variety of options including dry or gel-filled single and double-jacket designs, with plenum and riser ratings. Armored Cables Belden’s armored cables are designed to withstand harsh environmental conditions, including extreme temperatures, moisture, and physical damage. The armor layer provides an extra level of protection against mechanical stresses, such as crushing, impact, and abrasion, ensuring the longevity and reliability of the cable. It also helps to maintain cable integrity in areas prone to disturbances such as rodent activity. Connectors Belden’s connectors seamlessly integrate fusion splicing with field-installable connectors Belden’s connectors seamlessly integrate the advantages of fusion splicing with the ease of field-installable connectors, they greatly enhance flexibility for field termination, while elevating installation performance and reliability beyond traditional mechanical splice connectors. Eliminating the need for crimping, polishing, or adhesives during termination significantly reduces installation errors. Cassettes Belden offers an advanced DCX and LAN Cassettes platform designed to cater to a wide spectrum of density requirements, ranging from low to ultra-high density applications. Cassettes platform encompasses frames, cassettes, and covers for a comprehensive array of connector types, including LC, SC, ST, and MPO connectors, as well as Copper RJ45 Jacks and Couplers. Patch Cords Simplified, durable, adaptable, and readily accessible. Unmatched quality and performance define Belden's FX patch cords, engineered with a robust design to endure daily wear and tear. Available in standard configurations off the shelf or swiftly customized for tailored installations, they ensure reliability in any setting.

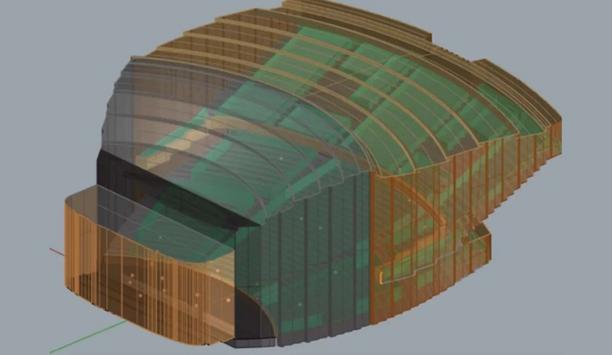

Siemens has developed a digital twin especially for large event spaces. The technology makes it possible to realistically reproduce and simulate very precisely a building’s acoustics and structure. The Sound of Science application will be used for the first time in the Großes Festspielhaus – the Large Festival Hall – at the Salzburg Festival. Sound of Science application Orchestral formations on the stage can also be tested and arranged in advance Sound of Science will enable event organizers to virtually explore how acoustics change in different spatial configurations – for example, how adding acoustic panels affects the listening experience – in order to select the optimal acoustic scenario. Orchestral formations on the stage can also be tested and arranged in advance – before a single note is heard in the real world. This approach saves money, resources and time. Siemens to use digital twins “With Sound of Science, we’re designing the future. Digital twins are not only transforming the everyday for many companies, but are also creating new opportunities for the cultural and creative industries,” said Prof. Dr. Stephan Frucht, Artistic Director of the Siemens Arts Program. Dr. Stephan Frucht adds, “In the future, we’ll be able to plan stage productions better and even simulate them acoustically in advance. We’re delighted to have the Salzburg Festival at our side as a long-standing partner, who recognizes the opportunities such innovations offer.” Sound of Science app for select partners Siemens will make the Sound of Science app available to selected partners from the cultural world free of charge as a demonstration application. There are currently no plans to market the application. Its simulation solutions, however, may be purchased. The Salzburg Festival’s Großes Festspielhaus is the first and only large event space to date in which Sound of Science is available. However, Siemens is planning to digitally simulate further spaces – including concert halls in Germany and England. At the Salzburg Festival, audiences will have an opportunity – unique for the time being – to use VR glasses to experience the application at the festival’s opening on July 20. Siemens and the Salzburg Festival “Siemens and the Salzburg Festival share a common passion for excellence and innovation. And we’re delighted to partake in this pioneering technological development and innovation as part of our long-standing close and trust-based partnership,” said Dr. Kristina Hammer, President of the Salzburg Festival. Dr. Kristina Hammer adds, “We’re excited to see what diverse applications will stem from Sound of Science in the future.” Siemens Simcenter’s simulation solutions The technologies used are part of the simulation solutions from Siemens Simcenter The technologies used are part of the simulation solutions from Siemens Simcenter, which has been part of the company’s core business for over 15 years. The technology is mostly used in industry – for example, for the acoustic optimization of vehicle interiors or for protection against street noise. For Sound of Science, Simcenter uses a combination of impulse response measurements and ray tracing for the 3D modeling of each event space. These methods can measure the echo and reverberation of a sound and simulate how sound waves propagate in a room. Depending on the material, reflections of sound waves behave differently. Those that bounce off a concrete wall react differently from those that hit a carpet or reach the ear directly. As a result, the simulation can reproduce the individual sound signature of each event space – in other words, its acoustic DNA. Siemens Festival Nights Siemens has been working closely with the Salzburg Festival for around 30 years. Since 1999, the company has also been the festival’s main sponsor. Since 2002, the Siemens Festival Nights have been held on Kapitelplatz square during the Salzburg Festival. Since its beginning, this open-air event has provided more than one million visitors with the opportunity to experience previous and current festival productions on an LED screen free of charge. In addition, some of the Salzburg Festival’s venues are equipped with Siemens technology from the areas of building automation, security and acoustics.

The project aims to increase the resilience of the city's transmission network, reducing dependence on energy supply from other locations, and meeting demand during the peak tourism season. WEG has just announced the supply of a complete energy storage system (BESS) for the city of Aspen, located in the state of Colorado, USA. The project aims to enhance the resilience of the local power grid, which does not have its own power generation system and is entirely dependent on generation from other cities. Microgrid management software The solution provided by WEG includes transformers, AC/DC voltage converters, battery containers, switching and protection systems, as well as advanced microgeneration or microgrid management software. The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy The initial system will have a capacity of 1.5 MW of power and 2 MWh of stored energy, with the potential to expand to up to 8 MWh when fully implemented. The management software is being developed by teams of specialists in the United States and Brazil, where WEG’s largest software development technical team is based. Implementation of the BESS system This project is yet another in the portfolio of BESS systems in the United States, where WEG has a group of engineers dedicated to this product in the cities of Duluth, GA, and Barre, VT. According to Carlos Bastos Grillo, Managing Director of Digital and Systems at WEG, the implementation of the BESS system will not only reduce dependency on external energy sources, but also increase the city's resilience against power supply interruptions during the peak season and dry periods, when wildfires occur more frequently in the region. Facing similar challenges "The guarantee of a stable power supply is vital for the sustainability of local tourism, which is the backbone of Aspen's economy. We believe that this project will not only benefit residents and visitors, but also serve as a model for other cities facing similar challenges," assures the Executive. The BESS system is scheduled to be completed by September 2024, preparing Aspen for the high ski season that starts in November. Timely completion will ensure that the city does not suffer from power shortages during one of the most critical periods for local tourism.

Jenkins sold a Jenkins Motor Test System to Oman, where temperatures can exceed 120ºF. While Jenkins Motor Test Systems are built tough and for industrial environments, this specific location required customizations to be the most effective in an extremely hot environment. Locations near large bodies of water or tropical environments can also cause problems as the humidity in the air will cause the copper wiring in the transformer to oxidize over time. Although Jenkins designs its equipment to operate for long periods, some applications for customer environments require specific customization. The Solution Jenkins engineers and winders worked together to develop a custom solution for this harsh climate, particularly paying close attention to temperature and water resistance. To customize the transformer for this environment, the Jenkins team made the following modifications: Doubling the spacing between winding layers to increase airflow. Encasing the transformer first in a high tolerance epoxy varnish, and then in a polyester over-dip that prevents the application from rust, dust, and harmful materials. Utilizing expanded metal at the base of the MTS enclosure, allows heat to escape, reducing the internal temperature. Installing temperature-sensitive cooling fans (set to 100ºF) atop the enclosure to prevent overheating. The Results Jenkins technicians checked insulation for 10,000 volts (resistance to ground), checked each voltage leg, and high voltage potential to ground, and ensured the taps were in the correct place. Voltage was confirmed to operate up to 20% above normal operation, ensuring maximum efficiency and longevity of the transformer. These modifications have resulted in prolonged use of the Jenkins Motor Test System in harsh environments and ultimately customer satisfaction.