Mitsubishi Electric Corporation - Experts & Thought Leaders

Latest Mitsubishi Electric Corporation news & announcements

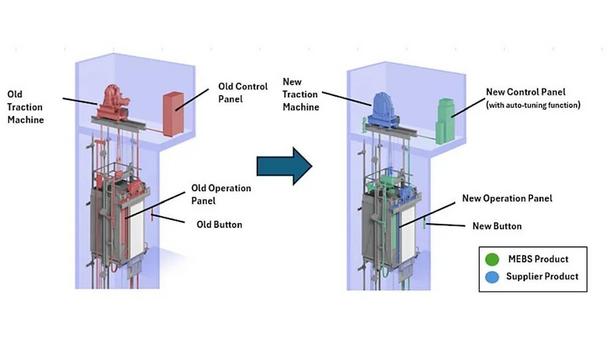

Mitsubishi Electric Building Solutions Corporation (MEBS, Head Office: Chiyoda-Ku, Tokyo; President: Iwao Oda) announced the launch scheduled for 19 March of a new overseas control renewal menu for elevators made by other companies installed in existing buildings. By developing a new control panel with an auto-tuning function, MEBS will respond to the diverse needs of its overseas customers for the renewal of control systems for elevators, while spurring the expansion of its maintenance and renewal business. Main Features of Renewal Menu 1) Achieving control that maximizes ride comfort even with other companies' traction machines through auto-tuning It is possible to upgrade to the latest control system by utilizing an MEBS control panel together with a traction machine made by another company. The newly developed control panel equipped with an auto-tuning function estimates the characteristics of the other company’s traction machine and automatically derives the control parameters for the combination of the other company’s traction machine and the MEBS control panel. This eliminates the need to develop a dedicated control panel for the traction machine and improves ride comfort. 2) Improving safety and contributing to sustainability by promoting the renewal of existing elevators The renewal menu promotes the renewal of existing elevators to improve safety and convenience, and contributes to sustainability by reducing power consumption and waste emissions through the reuse of some of the equipment. The menu also reduces downtime by eliminating the need to replace all of the equipment. 3) Achieving improved convenience in response to diversifying building solution needs By adopting the renewal menu, it is possible to introduce integrated building solutions utilizing MEBS’s unique technologies such as the global remote-maintenance service M’s BRIDGE, DOAS (Destination Oriented Allocation System, elevator coordination with mobile robots, Elevator Call System with Smartphone, and BMS (Building Management System). Elevator parts manufacturers MEBS receives numerous requests from customers with existing elevators In the overseas elevator market, there are many elevator parts manufacturers and specialized elevator maintenance companies that respond to diverse customer needs. With such a wide variety of choices available, MEBS receives numerous requests from customers with existing elevators made by other companies to provide them with higher-quality services by renewing their control systems using the control panels. MEBS’s newly developed control panel Normally, when combining a control panel with a traction machine from a different manufacturer, it is necessary to develop an individual control panel that matches the characteristics of the traction machine. However, by adopting MEBS’s newly developed control panel equipped with an autotuning function, there is no need to develop a dedicated control panel for each traction machine, and the latest control technology can be introduced while utilizing other companies’ traction machines. New autotuning function-equipped control panel The control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators As a result, performance can be improved while reducing costs and ensuring stable long-term operation. Until now, the control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators, but with this new autotuning function-equipped control panel, they can now offer control renewal for existing elevators made by other companies, which will allow us to meet an even wider variety of customer needs. Outlook MEBS, which is in charge of the building systems business, a key growth area for Mitsubishi Electric, is planning to expand and accelerate the global elevator maintenance and renewal business as a priority strategy. Through this menu, they are aiming to renew 1,000 elevators annually by 2030, mainly in North America and Europe.

Mitsubishi Electric Corporation announced that it has signed an agreement with HD Renewable Energy Co., Ltd., a Taipei-based developer and operator of solar power and battery storage systems, to collaborate on initiatives that will help realize carbon neutrality. As part of their collaboration, the companies will establish an aggregation business joint venture and Mitsubishi Electric will acquire a stake in HD Renewable Energy. Profitability of power generation Amid rising fuel costs and global efforts to realize carbon neutrality, Japan is actively promoting the adoption of renewable energy. However, owing to fluctuations in power generation from renewable sources such as solar and wind resulting from their dependence on seasons, weather, and time of day, transmission system operators are required to continuously monitor the demand for power and fine-tune adjust supply and demand. Against this backdrop, there is an expansion in the aggregation market, where multiple distributed energy resources (DERs), such as renewable energy generation facilities and battery storage systems, are utilized to help stabilize power grids and maximize the profitability of power generation and storage businesses.

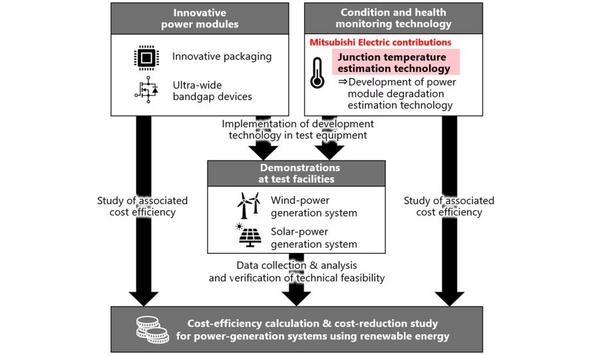

Mitsubishi Electric Corporation announced that it will begin developing a prototype to demonstrate a junction-temperature estimation technology for power modules. The company is pursuing this technology as a partner in the European Union's Horizon Europe project, which aims to develop advanced power modules and improve the cost efficiency of renewable energy power generation. The company is participating through its European subsidiary Mitsubishi Electric R&D Centre Europe B.V., which has joined the project, called Flagship Advanced Solutions for Condition and Health Monitoring in Power Electronics (FLAGCHIP). reliability and maintenance The need to upgrade the reliability and maintenance of electronic devices for power conversion has become increasingly important in the global effort to expand the introduction of renewable energy to support carbon neutrality. Attention is being focused on technological innovations that aim to strengthen power module reliability and improve data acquisition and analysis methods. These innovations aim to accurately determine degradation conditions and facilitate more timely maintenance. cost efficiency Wind-power and solar-power generation systems will be demonstrated using these technologies The FLAGCHIP project currently involves 11 companies and academic institutions from nine European countries engaged in developing advanced power modules, condition and health monitoring technologies, and devising methods for calculating the cost efficiency of renewable-energy power-generation systems and reducing associated costs. Wind-power and solar-power generation systems will be demonstrated using these technologies and methods at test facilities owned by project partners in Norway and France. estimating module degradation Mitsubishi Electric will be in charge of demonstrating a technology that estimates the junction temperature of silicon carbide metal-oxide-semiconductor field-effect transistor (SiC-MOSFET) semiconductor chips inside the power module, which will provide necessary data for accurately estimating module degradation. Starting in October 2026, the demonstration will use the newly developed prototype at a test facility in France where direct current (DC) voltage is converted to a specific DC voltage for a wind-power generation system.