FURUKAWA ELECTRIC CO., LTD. - Experts & Thought Leaders

Latest FURUKAWA ELECTRIC CO., LTD. news & announcements

Furukawa Electric successfully operated the FRL1441U Series pump lasers for high output, low power consumption Raman amplifier in the C-band at 55℃, and by reducing reactive power by more than 50%, the newly developed LD chip consumed 3.7W at 500mW fiber output, which is less than half the 8W power consumption of existing LD chips. In addition, they have started the development of mass production technology. While communication traffic volume at data centers and elsewhere has been increasing on the background of the popularization of cloud service and the emergence of generative AI, along with increasing data transmission speed, the transmission distance decreased due to degradation of the OSNR on the signal receiving side. Faster transmission speeds In particular, when existing communication systems are used at faster transmission speeds, the role of the Raman amplifier, which can amplify optical output power without attenuation of the signal light quality, will become more important. Also, because the bandwidth of the signal expands as a result of high-speed transmission, it is necessary to extend the bandwidth in order to enable high volume transmission. Raman amplifiers need to have high flexibility to amplify the light source at a discretionary range Thus, Raman amplifiers need to have high flexibility to amplify the light source at a discretionary range based on the selection of the pump laser wavelength. On the other hand, in addition to the traditional C- and L-bands, with the expansion into the S- and U-bands, the number of pump lasers used increases, so it is even more important for them to have high output power and low power consumption. Thermoelectric cooler element For pump lasers, reducing the power consumption of the thermoelectric cooler element leads to reducing overall pump laser power consumption. When pump lasers are used in hot environments, it is necessary to cool the LD chip, but this increases the power consumption of the thermoelectric cooler element, causing overall pump laser power consumption to rise. Therefore, enabling the LD chip to operate at high temperatures is important for reducing pump laser power consumption. The FRL1441U Series reduces the power consumption of the pump lasers used for existing Raman amplifiers in the S-, C- and L-bands by 37%. In addition, development of a dual port pump laser makes it possible to reduce the space used by using 1 pump laser instead of the previous 2 units. This time, they achieved 840mW output in the C-band at an LD chip operating temperature of 55℃ by 14 pin butterfly package platform. Mass production technology This achievement was made by optimizing the LD chip to realize with higher laser output This achievement was made by optimizing the LD chip to realize with higher laser output and reduced electrical resistance of the laser element. Also, through large reduction to reactive power by operating the laser element at 55℃, they confirmed that power consumption of the widely used 500mW fiber output LD chip is reduced to 3.7W, which is less than half of the 8W power consumption of existing products. They have started development of mass production technology. This development uses their optical semiconductor processing technology using InP semiconductor materials developed over more than 25 years and high accuracy fiber coupling technology, as well as the application of their unique low loss, high efficiency semiconductor laser device structure. It also takes advantage of the optimized design of their patented high efficiency semiconductor laser device structure. Module power consumption An oral presentation of this product will be made on July 2 at OECC 2024 to be held in Melbourne, Australia in July of this year. The current development was conducted and achieved as part of the National Institute of Information and Communications Technology (NICT) commissioned research ‘Beyond 5G – Development of extended rate optical node technology for realizing ultra-high speed, large volume networks’ (Key Issue JPJ012368C04501) and the 2024 Function Realization and International Joint R&D Program ‘Innovative ICT Fund Projects for Beyond 5G/6G’ (JPJ012368G60101). Going forward, they will continue to develop high output, low power consumption laser chips, and contribute to accelerated reductions in module power consumption and the establishment of environmentally-friendly networks.

In order to realize 5G communications with characteristics including ‘high speed and large volume,’ ‘high reliability and low latency’ and ‘multiple simultaneous connections,’ in addition to Sub-6 frequency, the broad, high frequency submillimeter wave band has been allocated as the communications frequency. With the planned introduction of Beyond 5G/6G in the future, it is expected that an even higher frequency broad wave band will be adopted. Given this, low dielectric materials that can more effectively transmit radio waves and signals will be required for the radome housing at base stations (cover that houses the radar antenna and protects it from the weather and sunlight), as well as for the antenna substrate and phase shifter substrate. Low dielectric plastics Utilizing their original technology, they have developed Smart Cellular Board™, a board type low dielectric material. It is possible to improve the dielectric characteristics of various low dielectric plastics by foaming highly heat resistant plastics such as engineering plastic and super engineering plastic. Also, because the foaming process reduces the density of the material, this new development will contribute to reducing the weight of the base station components. Traditionally, solid (non-foamed) plastic materials have been used for base station radomes, but Smart Cellular Board™ realizes increased radio wave permeability and a lower dielectric constant (Dk) and dissipation factor (Df) through the introduction of micro-foam. The lower density will also contribute to reducing the weight of the radome. In addition, the excellent forming and machining characteristics make it possible to supply Smart Cellular Board™ in various forms. Impact of dielectric loss The base station will be equipped with large heat sinks for thermal management In the high frequency wave band used for Beyond 5G/6G, because the same high frequency signal will pass through the antenna and RF components at the base station, the impact of dielectric loss tends to increase compared to the traditional lower frequency signals. Also, because this dielectric loss will lead to increased heat being generated, the base station will be equipped with large heat sinks for thermal management. In response to these issues, Smart Cellular Board™ minimizes substrate dielectric loss through its excellent dielectric characteristics, and as a result, it will contribute to limiting heat generation from the substrate and reducing the weight of the heat sinks. Infrastructure combining information They will continue to contribute to the realization of a Beyond 5G/6G society through the development of products that utilize their original technology. Based on the ‘Sustainable Development Goals (SDGs)’ adopted by the United Nations, Furukawa Electric Group has formulated the “Furukawa Electric Group Vision 2030” which sets the year 2030 as its target and is advancing efforts with the aim to ‘Build a sustainable world and make people’s life safe, peaceful and rewarding, Furukawa Electric Group will create solutions for the new generation of global infrastructure combining information, energy and mobility.’ Toward the achievement of their Vision 2030, they will take open, agile, and innovative approaches to promote ESG management that aims to increase corporate value over the medium to long term and will contribute to the achievement of the SDGs.

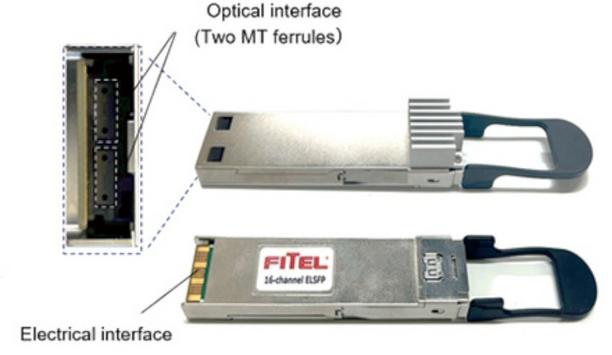

Furukawa Electric Co., Ltd. has developed the world’s first 16-channel ELS employing a blind mate optical connector for the realization of next-generation network switch servers employing CPO for hyperscale data centers and edge data centers. With the growth of cloud services, 5G, and other new telecommunications services, as well as generative AI (Artificial Intelligence) and machine learning, data traffic has been increasing at an annual rate of approximately 30%. Hence, hyperscale data centers and edge data centers are faced with the challenges of expanding bandwidth and reducing of power consumption of network switch server equipment. To expand bandwidth and reduce power consumption, it has been expected to employ CPO as a new server architecture. Network switch equipment CPO ELS is required to have multiple channels with high optical output power and also ensure eye safety CPO ELS is required to have multiple channels with high optical output power and also ensure eye safety. In August 2023, OIF (Optical Internetworking Forum) published the ELSFP (External Laser Small Form Factor Pluggable) IA (Implementation Agreement) as the specification for a CPO ELS. This agreement adopts a structure that integrates a blind mate optical connector at the same facet of an electrical card edge, and since a blind mate optical connector is located inside a network switch equipment, laser beams are never outputted from an ELS to outside of the network switch equipment. Therefore, this structure is preferable for eye safety. Therefore ELS should integrate a blind mate optical connector, control circuitries implemented on a PCB, TOSAs, and an MT connector into a housing without any degradations of the characteristics. The maximum channel number of ELSFP is specified as many as 16. Integrate the high-power DFB Developed a 16-channel ELSFP module employing a blind mate connector and two eight-channel TOSAs, which densely integrate the high-power DFB (Distributed Feedback) lasers and optical components. The eight-channel TOSA is as small as 22.5 mm(L) x 13.0 mm(W) x 3.3 mm(H), and in order to fit the polarization-maintaining fibers inside the ELS housing without finer bend loss and degradation of polarization extinction ratio, the fiber length has been reduced. The fabricated 16-channel ELS achieved fiber-coupled optical power of 100 mW for all channels and a polarization extinction ratio of <20 dB at a case temperature ranging from 25°C to 55°C. They plan to launch sample delivery from April and the commercialization is planned to start in FY2025. OFC 2024 OFC 2024 scheduled to be held on March 24-April 5, 2024 in San Diego During OFC 2024 scheduled to be held on March 24-April 5, 2024 in San Diego, they will exhibit the CPO ELSs and TOSA for four days from March 26 (FITEL-FURUKAWA ELECTRIC EUROPE booth; Booth number 2041). Going forward, they will continue to contribute to the realization of large-volume data communications and an energy-efficient society through the provision of ELS required for the adoption of CPO. Key characteristics Number of channels: Maximum 16 Operating case temperature: 0 to 55 °C Wavelength allocation: Option 1: 1311 nm x 16; Option 2: 4-l CWDM x 4 Optical power: >100 mW/channel Polarization extinction ratio: >20 dB Power consumption: <13 W