Canyon State Electric - Experts & Thought Leaders

Latest Canyon State Electric news & announcements

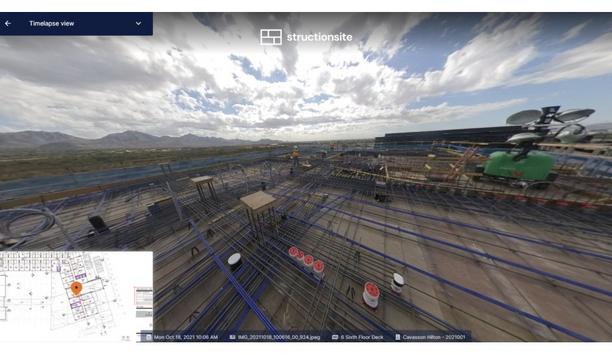

As an electrical sub-contractor, daily jobsite documentation is critical for Canyon State Electric to ensure quality control and share on-site progress with key stakeholders. Before using StructionSite, capturing, organizing, and sharing photos was disjointed. Canyon State Electric had to rely on the foreman to capture site progress, who then had to fill out a Google Form to track pictures and log them into the CSE systems. The office coordinator was responsible for going through these images and organizing them by date. Still, it was difficult to determine where the foreman took each photo without critical location information. COVID-19 hit the construction industry - hard Canyon State Electric decided to tackle the problem of capture efficiency with StructionSite Then the COVID-19 pandemic hit the construction industry – hard. The same volume of work had to be completed with fewer people on-site, teams were spread across different locations, and checking in on work progress had to be done from remote environments. After hearing about StructionSite during AutoDesk University, Canyon State Electric decided to tackle the problem of capture efficiency and remote-based collaboration with StructionSite. Constant stream of information via 360 site documentation With a task like taking manual photos, several variables and unknowns – like photo-taking experience, hardware quality, and schedule availability – can impact the ability to capture the information and context needed. Using StructionSite and state-of-the-art capture devices has enabled Canyon State Electric to ensure site documentation is constant and consistent in the frequency and quality of the data captured. Focus on project management Office-based team members can now focus on project management, do more work with fewer people, and spend quality time producing more. They can showcase their work through high-quality, detailed 360 images and videos to walk stakeholders through their processes and ensure a more collaborative building environment. Improving capture speed and data consistency Before StructionSite, Canyon State Electric had a dedicated team that solely focused on site capture While AI (Artificial Intelligence) and Machine Learning can do the information tagging and organization work, manpower is still required to actually capture the image data that feeds into Canyon State Electric’s systems. Before StructionSite, Canyon State Electric had a dedicated team that solely focused on site capture and safety by walking jobsites every day, for 1-2 hours a day. Improved speed and efficiency brought by StructionSite With the improved speed and efficiency brought by StructionSite, documentation is now built directly into their schedules to capture significant milestones, before and after they are completed. These images become a priceless resource to prove the quality and timing of when and how Canyon State Electric’s team completed work. A consistent schedule for capturing site progress provides a stream of visual proof and assurances when going into stakeholder meetings. The ROI of documentation for electrical subcontractors Electrical subcontractors are frequently impacted by the typical risks involved in construction (like plan changes, site conditions, material and labor shortages, adverse weather, etc.). They also often have to deal with inadequate coordination between parties, scheduling errors, and slow delivery. When these claims inevitably arise, there is nothing worse than needing a photo to address a claim and spending hours looking for it just to find that it doesn’t answer the questions. Visual data plays a key role One 360 photo can lead to thousands of dollars in savings by addressing claims head-on with unbiased proof For Canyon State Electric, the images and organization provided by StructionSite allow them to quickly and easily find what they need, when they need it, through visual data. One 360 photo can lead to thousands of dollars in savings by addressing claims head-on with unbiased proof. The virtual walkthrough of work also enables Canyon State Electric to provide stakeholders with a thorough overview of jobsite progress and show that their work is on-time and completed. Creating a custom learning portal Everyone in the industry knows photo documentation is crucial for communication and quality control on any construction project. But what some fail to realize is the potential to use this data for training purposes. Staffing is a huge problem facing the trade industry. How to recruit and train the staff needed to complete work, ensure quality, and remain profitable? Unique approach to StructionSite Canyon State Electric has taken a unique approach to StructionSite and leveraged their capturing data to create their own custom learning portal for incoming electricians. At any given time, there are massive amounts of talent brought into the company with a variety of experiences. As new electricians come on board, the platform becomes a virtual learning portal to provide onboarding training. New hires are sent to the training room and shown a walkthrough of previous Canyon State Electric jobs, priming them for field experience. Once they set foot on a jobsite, they already know the etiquette and expectations, giving them more confidence to perform their duties. Safety managers use StructionSite for training Safety managers use it for training, like showing real-life examples of the risks that can arise on a jobsite Safety managers use it for training, like showing real-life examples of the risks that can arise on a jobsite. Some new hires may have never stepped foot on a project before, and now they can get an inside look into the jobsite environment before they are fully trained. Instead of using hypotheticals and going into the unknown, the staff is more aware of the potential safety risks, before hitting the field by visibly seeing what a jobsite looks like and what to look out for, which ultimately lowers the number of incidents and improves work quality. Historical view of projects Instead of bringing untrained talent to many job sites, Canyon State Electric can look at previous jobs within StructionSite and walk new hires through the entire electrical process. The historical view of projects enables Canyon State Electric to set expectations, teach about techniques and processes, and walk new hires through the different construction sectors and what happens on each project type. Raghav Chandra, VDC Manager, Canyon State Electric, said “When you train people on a system that is clunky, frustrating, and hard to use, it no longer serves a benefit for you. People want to get more involved with a system like StructionSite that is so much easier to use and access.” Full circle of highly-trained individuals Raghav Chandra adds, “People want to use their photos more, capture more, and leverage innovative technologies daily. We create this full circle of highly-trained individuals dedicated to using the technologies we provide them, which then feeds back into our university to continue training new talent.”

Canyon State Electric (CSE) is collecting Lego sets throughout the month of November, 2022 to benefit local children in the foster care system. Canyon State Electric’s Lego Drive is held during the holiday season each year, and sets collected in 2022 are being given to Arizona Helping Hands for their Holiday Toy Drive. Canyon State Electric’s Lego Drive The Lego Drive began in 2021, after the passing of Canyon State Electric’s Founder, Steve Maderazzo. He famously loved building with Lego, creating many structures, including a replica of the CSE office building. The Canyon State Electric team honors Steve Maderazzo's legacy with generosity The Canyon State Electric team honors Steve Maderazzo's legacy with generosity, donating Lego sets to children in need of toys each December. Collecting Lego sets for a good cause In its first year, the Lego Drive collected nearly sixty sets; the company hopes to raise over one hundred sets this year. Sets of all sizes, prices, and age requirements are accepted. To donate, bring a Lego set to Canyon State Electric’s office at 4640 E McDowell Road, to schedule a pickup.

Canyon State Electric (CSE) received national recognition from Independent Electrical Contractors (IEC) for excellence in safety. From a group of 3,600 member businesses nationwide, CSE was among one dozen companies with the distinction of Superior Achievement in Safety. The award, which was announced during IEC’s annual SPARK conference, scores a safety department in over twenty categories, including upper management/owner commitment, employee participation, use of personal protective equipment (PPE), and recordkeeping. Canyon State Electric earned the maximum amount of points in all categories. Safety “Safety is the company culture,” said Sidney Hawkins, Canyon State Electric’s safety and training manager. “Our staff focuses on the safety of the person working near them." Safety is our number one core value, and we have ensured at each level of the company" "They genuinely care about each other. That mindset makes Canyon State one of the safest companies I have ever worked for. Canyon State Electric President Robert Hughes said, “We want everyone to go home to their families healthier and wealthier each day. Safety is our number one core value, and we have ensured at each level of the company, it is our highest priority. We talk the talk and walk the walk.” health and safety processes CSE currently has a three-year agreement with the Arizona Department of Occupational Safety and Health (ADOSH) to strengthen the company’s health and safety processes even further. Since signing the agreement, Canyon State Electric has maintained an experience modification rating used to measure a company’s job site safety with regards to insurance premiums under 0.7, thirty percent lower than the industry average. Near the end of the three-year agreement, the company will start the process for OSHA Voluntary Protection Program (VPP) application. The VPP star distinction is OSHA’s highest level of recognition. “We are already looking beyond VPP. What comes after VPP? That’s what we want,” said Hawkins.