BAE Systems - Experts & Thought Leaders

Latest BAE Systems news & announcements

Austin is continuing a decade-long growth trend with no sign of slowing, with new commercial towers redrawing the city’s skyline, while multi-family complexes and commercial spaces are springing up across Travis County, in Texas, USA. Electrical contractors are busy. In addition to at least three skyscrapers under construction and numerous new manufacturing sites, a courthouse and a hospital, there are also large-scale construction projects underway for companies, such as Samsung, Tesla, The Boring Co. and Apple. Austin, a booming center for technology and business By early 2021, 34% more companies were operating within the borders of the city of Austin, Texas, than in 2016. New business means more residents, too. Austin’s population recently topped 1 million, while the greater Austin-Round Rock metropolitan area includes 2.3 million, an 84% increase since 2000. “With this massive influx of people and business in the region, there is an incredible amount of building that is being done and will need to be done to accommodate all of it,” said Bryce Bencivengo, the Director of Public Relations and Media for the Austin Chamber of Commerce. Multiple construction projects in Austin It’s hard to state just how many construction projects are underway or planned for the region" “It’s hard to state just how many construction projects are underway or planned for the region,” said Bryce Bencivengo, adding that “All of these investments by businesses and developers are vital to our region’s growing economy and continue to help us diversify the industries that are located here.” Electrical contractors serving the region vary from large, multi-state companies, to small family-owned operations, some of which have been working in the Austin area for generations. Elk Electric Inc. For more than 60 years, Elk Electric Inc. has provided electrical construction services in the greater Austin area. Having begun with standard commercial construction, the company recently expanded into electrical service and maintenance, low-voltage fire alarms, network cabling, security and access-control CCTV, energy consulting and constructing solar/wind/storage sites. Elk Electric excels at design-build projects and engineering services, and the company recently opened a mechanical and plumbing division. It is also building a prefab site to provide off-site construction for large projects. Mike Kanetzky, Elk Electric’s President, said “As projects accelerate across the region, the company has a presence across Austin and its surrounding cities, such as at the University of Texas at Austin (UT Austin). Elk Electric provides remodeling work at the school, as it expands and upgrades.” Network installation of 5G services Most recently, the company provided the network installation of 5G services there for Houston-based communications infrastructure and general contractor - Crown Castle, consisting of a full 5G network across the campus that offers higher bandwidth, greater speeds and battery life improvements. The rollout includes innovation in 5G connectivity that comes from the school’s laboratories The rollout includes innovation in 5G connectivity that comes from the school’s laboratories: small cell nodes, low-powered antennae that provide wireless coverage the way traditional cell towers do, but are more discreet and deployed closer to smartphones, and other devices, by being attached to existing infrastructure, including utility poles and streetlights. This work is ongoing in Houston and Austin, in Texas, USA. Partnership with BAE Systems Additionally, Elk Electric is working with global defense contractor - BAE Systems by providing tool hookup, as the company occupies a newly constructed facility. BAE Systems—one of the world’s renowned aerospace and defense companies—has had a presence in Austin since the 1960s. The company recently expanded its operations at its new Palmer Austin business park site, where it intends to conduct manufacturing, engineering, laboratory and office work. With the new building already constructed, Elk’s installation work will ensure electric service to the equipment used for production at the new facility. Unique role in manufacturing for other firms Elk Electric also has a unique role in manufacturing for other companies, such as Frito-Lay. The company remodels conveyor systems for the global snack manufacturer across the country. Elk Electric also provides shelving units for Frito-Lay. “We send out two to six travel crews at any one time, traveling around to different plants all over the country,” building out the necessary shelving, Kanetzky said. The EC also holds a complete maintenance program for the city of Austin. Part of that effort includes a maintenance contract for electric vehicle charging stations throughout the city. The company also provides mechanical, plumbing, electrical, carpentry, masonry and windows and doors for city-owned sites. BJ Electric Co. Family-owned BJ Electric Co., based in Pflugerville, Texas, has decades of history behind it Family-owned BJ Electric Co., based in Pflugerville, Texas, has decades of history behind it. The company specializes in outdoor lighting for recreation centers, parks, roadways and sports facilities and serves the central Texas region. The company provides Musco Lighting installations throughout the state, including facilities at the University of Texas. “We have been in the electrical construction business since 1982,” said Jack Payne, BJ Electric’s President. Sports lighting installations and warranty work BJ Electric’s sports lighting installations and warranty work throughout Austin began in the mid-1990s. Recent projects include deploying and maintaining the sports lighting at UT Austin’s Lee and Joe Jamail Swim Center, the Westwood Country Club and UT Austin’s Whitaker Fields (once the university’s intramural fields), which features 35 lighted tennis courts, four lighted outdoor basketball courts and four lighted sand volleyball courts. BJ Electric also illuminated the Old Settlers Fields in Round Rock for the city’s parks and recreation department and high school and college fields in San Antonio, Abilene, Lockhart, Killeen, Jarrell, Pflugerville, Georgetown, Leander, Lake Travis and several private schools. The company’s work goes far beyond sports lighting. BJ Electric has also worked on lighting for customers such as the Texas Department of Transportation, UT’s Balcones Research Center and MD Anderson Cancer Center and Texas Disposal’s waste disposal facility. Morales Co. LLC The city of Austin depends on multiple electrical contractors for infrastructure The city of Austin depends on multiple electrical contractors for infrastructure, such as water and other utility services. T. Morales Co. LLC, Florence, Texas, works almost exclusively in industrial, municipal and private water and wastewater treatment infrastructure in addition to the medium-voltage electrical substation industry. “Most recently, that has included projects such as a substation replacement to help maintain reliable wastewater treatment for city customers. T. Morales serve as prime contractor for the South Austin Regional WWTP electrical and related improvements project,” said Randy Eldridge, T. Morales’ Owner and COO. This wide-scale project requires four years of work and is scheduled to be completed in 2024. New electrical substation building and electrical vaults The electrical contractor’s role includes installing the new electrical substation building, electrical vaults and more than 100,000 feet of electrical 5-inch, medium-voltage duct bank assemblies. It also includes new 15-kilovolt (kV) distribution conductors, new 15 kV-rated electrical substation equipment, switchgear and substation transformer equipment, and the required instrumentation and miscellaneous plant process improvements. North of Austin, T. Morales also recently served the city of Georgetown’s South Lake Water Treatment Plant and Raw Water Pump station project. Another four-year project, this one is scheduled to be completed in mid-2026. Two new facilities added “It’s hard to state just how many construction projects are underway or planned for the region. All of these investments by businesses and developers are vital to our region’s growing economy and continue to help us diversify the industries that are located here.” The work consists of two separate new facilities. The first site includes a new 20-million-gallon-per-day conventional water treatment facility with all new supporting process structures, 600V, 5 kV, 15 kV and 25 kV electrical distribution subsystems and electrical switchgear and motor control systems. Medium-voltage variable frequency drives (VFDs) It also includes the medium-voltage variable frequency drives (VFDs) It also includes the medium-voltage variable frequency drives (VFDs) and all necessary plant process instrumentation, and the SCADA system. Also included in this site is a large, medium-voltage paralleling generation system with 5 kV paralleling switchgear and three 5 kV medium-voltage diesel-powered generators capable of providing up to 6 megawatts of backup power. The second South Lake site — the Raw Water Pump Station at Lake Georgetown — will provide all required water to the new 20-million-gallons-per-day treatment plant. This new facility consisted of the new raw water intake facility itself, with new medium-voltage submersible pumps, a new electrical building, new medium-voltage primary and paralleling switchgear, and two new medium-voltage diesel-powered generators capable of providing up to three megawatts of backup power generation. Morales also provided the medium-voltage duct bank and manhole assemblies, required process instrumentation and the SCADA software system. Beyond these projects, T. Morales continues to serve a wide variety of complete water or wastewater and electrical substation projects as demands increase. Alterman Inc. Another long-time fixture in the central electrical contracting sector is Alterman Inc., based in San Antonio, Texas, with an office in Austin. The company has been in business since 1923 and specializes in commercial and industrial markets. “Alterman’s many divisions allow it to specialize in a variety of project types, ranging from data centers and hospitals to manufacturing facilities, low-voltage data/audiovisual/security systems, water and wastewater, controls or programming, arenas and stadiums. Its Austin division recently took on UT Austin’s Red River Street Realignment Project to add updated lighting, traffic signals and security to a new roadway,” said David Deschaine, Alterman’s Director of Special Projects. Street alignment project This street alignment project consists of a ¾-mile new stretch of road through the UT campus" David Deschaine adds, “This street alignment project consists of a ¾-mile new stretch of road through the UT campus, bringing traffic more directly through the school. The original Red River Street — which looped around the east side of the campus — needed to be rerouted to meet the changing traffic needs of the growing university.” He continues, “So the school has built the new thruway to meet other recent improvements to the campus, such as the Moody Center basketball practice facility and the UT DKR End Zone football stadium expansion, both of which attract traffic. To provide services for the new roadway, UT has numerous concurrent projects underway, and that means careful coordination for contractors. Alterman scheduled its work to ensure there would be no interference with deliveries or school-related events such as football games and Texas Relays.” Full electrical installation at the UT DKR End Zone Alterman also provided full electrical installation at the UT DKR End Zone. This project enclosed the Texas Longhorns’ UT football stadium with a fourth side behind the south end zone, which had previously been open. The work included constructing stands, VIP suites, restaurants and concessions, as well as state-of-the-art coaching and workout facilities. Alterman upgraded generators and routed power feeds into and throughout the building with updated lighting and building automation controls. Alterman’s work extends to other public spaces Alterman’s work extends to other public spaces. At Austin’s Waterloo Park, for instance, the company provided the infrastructure for power and tele-data/audiovisual, including lighting, controls and power for the amphitheater and surrounding amenities. The company also serves several large hospitals in the area, providing building fit-out and all site and utility power. All jobs include normal and emergency power supplies, headwalls for inpatient and outpatient surgeries and treatment. Modernization to accommodate growth Looking ahead, the company is modernizing to accommodate growth Looking ahead, the company is modernizing to accommodate growth. Alterman has been focusing on transitions that include a prefab solutions division that takes a project from startup and preplanning, tracks the fabrication and site preparation, and follows it through the field installation. “This division (spends) countless hours and resources tracking different installation methods from some of our top electricians in the field,” adds David Deschaine. They analyze each method and then create a typical installation procedure that incorporates the most efficient processes from each one. This procedure is then documented and distributed to the field prior to the product showing up, which helps streamline the installation. More projects on the horizon In the meantime, more projects are being awarded throughout the central Texas area. Rosendin Electric Inc., based in San Jose, California, USA, has multiple offices in Texas and was selected for electrical construction at the new US$ 800 million hyper-scale data center for Meta (formerly known as Facebook) in Temple, Texas, working with general contractor, JE Dunn Construction. The Temple Data Center, 50 miles north of the Austin metropolitan area, will require a staff of 440 Rosendin electricians and prefabrication warehouse staff, BIM modelers, estimators and project managers. Overall, dozens of electrical contractors are playing a role in expanding the city, following a relative lull during the pandemic. “Local contractors and trades are critical to our responsibility to grow. They are a vital economic sector that makes this region’s growth possible,” said Bryce Bencivengo.

At the Joint Navigation Conference in San Diego, BAE Systems unveiled its newest advanced M-Code GPS receiver for guided weapons and other small applications, enabling precise geolocation and strike capabilities in highly contested battlespaces. SABR-M The Strategic Anti-jam Beamforming Receiver- M-Code (SABR-M) delivers accurate position, velocity, altitude, and timing data, as well as strong protection against GPS signal jamming and spoofing critical capabilities for unmanned aerial vehicles (UAVs), and the precision-guided munitions (PGMs), and missiles in threat environments. SABR-M integrates receiver technology with advanced antenna electronics in a small, hardened package designed to meet challenging performance requirements, such as weapons applications. It is the most capable integrated anti-jam GPS receiver and the first integrated M-Code receiver available for weapon systems. military GPS solutions We’re making M-Code-compatible meet warfighters’ need for reliable positioning, and navigation" “We’re making our full portfolio of military GPS solutions M-Code-compatible to meet warfighters’ need for reliable positioning, navigation, and timing data to achieve their missions,” said Doug Lloyd, director of weapon systems GPS at BAE Systems. “SABR-M enables small platforms with challenging environmental conditions to get where they’re going despite interference.” Compact and compatible The compact (4.5 x 6 x 1 inch) SABR-M meets size, weight, power, cost (SWaP-C), and thermal requirements for space-constrained military applications. It uses advanced beamforming technology to improve GPS signal reception and counter-threat signals. SABR-M is form-compatible with previous generations of the field-proven SABR receiver, which are currently integrated into low-cost precision weapon systems and long-range cruise strike missiles. Production details SABR-M will be fully qualified for production by the end of 2022. Production will take place at BAE Systems' modern facility in Cedar Rapids, Iowa, which is in the final stages of construction. The purpose-built 278,000-square-foot factory and research center will be home to 700 military GPS experts in BAE Systems’ Navigation and Sensor Systems business.

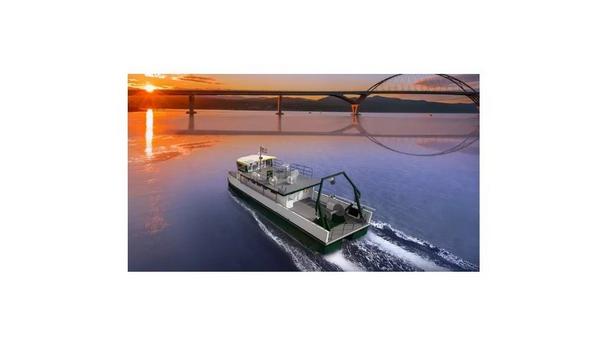

BAE Systems., a pioneer in electric propulsion, has been selected by Chartwell Marine to supply the electric hybrid power and propulsion system for a new maritime research vessel for the University of Vermont. hybrid system As part of the contract, BAE Systems will supply and integrate the hybrid system, working with the vessel’s builder, Derecktor Shipyard. BAE Systems’ HybriGen® Power and Propulsion system will help to reduce both carbon emissions and the use of fuel by the vessel, which will serve as a floating classroom and lab for students of the Rubenstein School of Environment and Natural Resources researching Lake Champlain. green energy The reliable technology will create a new and sustainable way for the University of Vermont to conduct its research" “Using green energy to power transportation in the water is an essential part of establishing cleaner waterways and harbors in places where we live, work, and visit,” said Steve Trichka, vice president and general manager of Power & Propulsion Solutions at BAE Systems. “This proven and reliable technology will create a new and sustainable way for the University of Vermont to conduct its critical research.” HybriGen Power and Propulsion system The fully integrated HybriGen Power and Propulsion system includes electric motors, variable speed generators, a battery-based energy storage system, and vessel auxiliary power with shore power charging. The technology creates a clean form of power and propulsion for the vessel and its auxiliary power needs such as heat, air conditioning, lighting, and working deck gear. The electric-powered components not only provide emission-reducing benefits to the environment but also create a smooth ride for passengers and help operators save on maintenance costs. integrating power and propulsion systems The technology builds on the company’s 20-plus years of experience developing and integrating power and propulsion systems. Those systems power more than 13,000 transit buses around the globe, including cities such as Boston, New York, and San Francisco. The new system leverages that core technology for the water with controls and components that have passed certification and inspection by the U.S. Coast Guard.