One of the largest packaging and disposable plastic industries in Santa Catarina/Brazil, Orleplast started its activities in 1992 by manufacturing plastic hoses. However, it soon concentrated its production on packagings such as bags, sacks, and rolls. From this change, the company obtained quality certifications to offer its customers better products. Today, the company produces about 600 tons of products monthly.

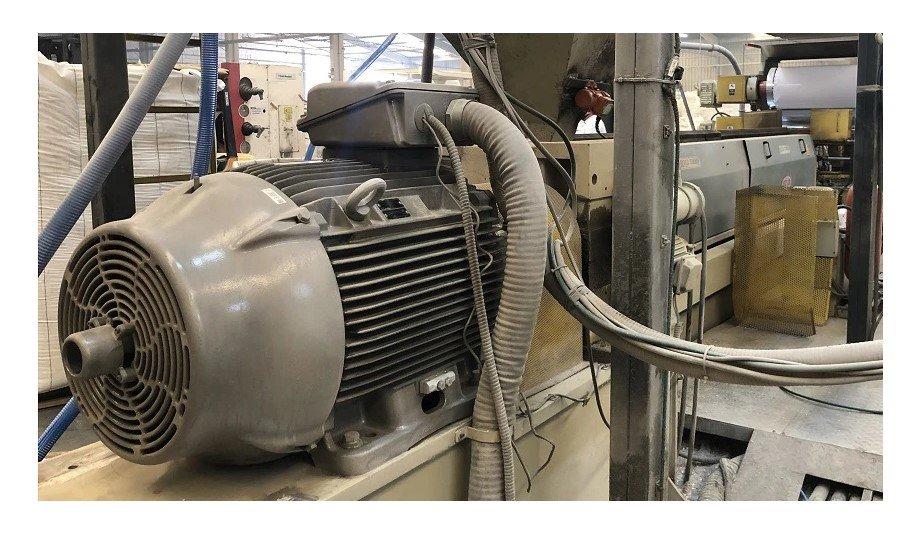

Seeking to further increase its productivity, Orleplast chose to invest in more efficient equipment for its production. In a partnership with WEG's Energy Efficiency Business Center, the company was specified a unique WEG technology in Brazil, the modern line of W22 Magnet electric motors, ensuring quality, performance, and energy savings to the industry.

W22 Magnet: the best performance rate on the market

The W22 Magnet is a line of motors that have permanent magnets in their construction. This lowers the temperature of the motor, enabling the reduction of its frame size in comparison to traditional induction motors.

W22 Magnet provides low maintenance costs, as bearings last longer due to lower operating temperatures

Another important feature is that the torque remains constant even at low speeds. In addition, the W22 Magnet provides low maintenance costs, as bearings last longer due to lower operating temperatures. At Orleplast, in addition to the use of W22 Magnet motors at 300 and 350 horsepower, the motor drive was replaced by the WEG CFW11 variable speed drive, bringing benefits such as machine position and speed variation, thus increasing the process energy efficiency.

Amazing results in energy savings

As part of the company's modernization project, the motors are installed in two plastic extruders and have already had a positive impact on Orleplast: a reduction in electricity consumption and a significant reduction in maintenance downtime.

According to an energy performance report, the savings amounted to 286,416 kWh/year (enough to supply 85 homes for one year), with a return on investment of 2.7 years. Such savings resulted in 36.2 tons of CO2 that are no longer emitted into the atmosphere annually.

energy efficiency solutions

In addition to all these gains, the replaced motors were sent to WEG as part of the payment for the new motors and were properly recycled according to the circular economy/reverse logistics criteria, always observing sustainability aspects.

Reputable for energy efficiency solutions for various industrial applications, WEG has a broad portfolio of products to offer the market efficient solutions that guarantee high performance, competitiveness, profitability, and sustainability to the industry.