Many engineers prefer to choose a power supply with ample “headroom” – In a worst-case scenario, if the application draws a power of say, 5W, then a 10W power supply will be selected.

The rationale behind this is that a certain factor of safety is required for maximum reliability in addition to making sure that if extra features are added to the application circuit in the future, there will be enough spare power supply capacity to cope with any additional load. These are powerful arguments that are difficult to counter, but it is not always the most efficient way to design a power supply.

typical efficiency/load graph

Consider a typical efficiency/load graph for a 10W AC/DC power supply (e.g., RAC10-12SK/277):

The efficiency overload graph is quite flat for all loads approximately over 20%, which is good, but at 50% load (5W), the efficiency varies between 77% and 81% depending on the supply voltage (Figure 1, orange line). At 100% load, the efficiency remains constant at 83% irrespective of the input voltage (Figure 1, blue line).

This difference may not seem significant, but 77% efficiency means that 30% of the supplied energy is wasted as heat, while 83% efficiency means only 20% is wasted – a significant reduction in the dissipated power.

supply voltage

If the power supply was replaced with an equivalent 5W rated part, say the RAC05-12SK/277, then the efficiency would be a constant 83%, irrespective of the supply voltage (Figure 2).

Further, not only is its operating efficiency greater, but the size of the 5W part is also almost half compared with the 10W part’s size; it is also cheaper – a win-win scenario.

Peak power vs average power

If the converter is operated continuously at the worst-case load, it could still handle this power level comfortably

However what about peak power? How will a power supply operated under the worst-case continuous load conditions also cope with any additional short-term peak overloads? The key phrase here is “worst-case” – during normal operation, the load will usually be less than this power demand. If the converter is operated continuously at the worst-case load, it could still handle this power level comfortably, although the actual load will be much less in practice.

This gives the converter some “thermal headroom” to also handle short-term peak overloads that are higher than the continuous operating load. For example, the RAC05-SK/277 datasheet presents a calculation to work out the peak load capability (Figure 3):

peak output power

RAC05-SK/277 has a nominal output power of 5W although it can deliver 6W without the overload protection

An important figure here is PP – the peak output power. The RAC05-SK/277 has a nominal output power of 5W although it can deliver 6W without the overload protection being triggered.

For overloads less than 120% nominal load, the limiting factor is the internal temperature of the components inside the converter. If the converter is given enough time to cool down in between overload events, it can then withstand multiple or cyclic overloads and still deliver a stable output voltage.

external output capacitor

For very short, very severe overload events, an external output capacitor can be installed to provide the required peak current and stop the converter from going into overload protection.

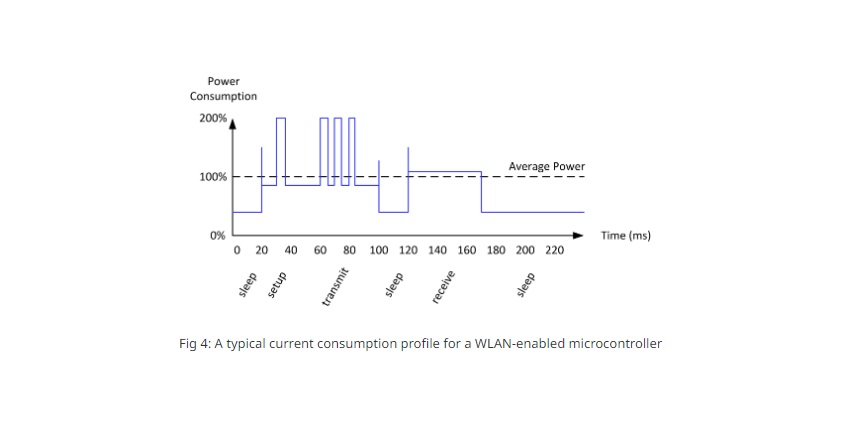

This is useful for applications such as wireless-connected microcontrollers wherein the current peaks during the transmission bursts are very short, high-power events, but the average power consumption is much lower (Figure 4). In this case, the power supply can be dimensioned to provide the average power rather than the peak power.

Up to this point, RECOM has considered AC/DC converters, but DC/DC converters can also be given the same analysis. The difference between them is that DC/DC converters are designed to be continuously operated in the 80–100% output power range, and their efficiency curve drops even more quickly if used at much lower loads.

Therefore, operating them at a low output current does not always mean that they run much cooler. In general, using a 10W DC/DC converter at a 5W load should be avoided, unless there is no other way to meet the required operating temperature range specification except by power derating. For example, the RS12-Z series delivers an impressive 12W of isolated power in a compact SIP8 case (21.8mm x 9.6mm).

RS12-Z converter

Even 6W in a SIP8 case operating in the full industrial temperature range with only free-air convection cooling

With natural convection cooling and a nominal 24V supply, the RS12-Z converter can operate at full power at up to 75°C, while by derating the load to 50%, it can operate in the industrial temperature range of -40°C to +85°C. Thus, halving the load provides only a +10°C additional ambient temperature range because the converter is no longer operating at its highest efficiency.

Nevertheless, even 6W in a SIP8 case operating in the full industrial temperature range with only free-air convection cooling is still significantly better than the competition, which has to resort to forced air cooling to deliver the same output power.

Over-current protection

Many low-cost AC/DC and DC/DC converters have a very simple output over-current protection circuit based on detecting the voltage drop across an internal shunt resistor (Figure 5).

Such internal protection circuits, while simple to implement and highly effective as short circuit protection, have a wide overcurrent limit variation as the trigger point is heavily dependent on the tolerance of the shunt resistor and the VBE threshold voltage of the NPN transistor.

wide overload tolerance

Such converters can be reliably operated at continuous full load and still have significant headroom

The component values are therefore determined so that the overcurrent protection does not nuisance-trigger above the entire ambient operating temperature range at 100% load.

This gives the converter a very wide overload tolerance at room temperature – typically up to 140% of the nominal output power. Such converters can be reliably operated at continuous full load and still have significant headroom to cope with any overload conditions.

DC/DC switching regulators

An exception to this generalization is the DC/DC switching regulators that typically operate at a higher switching frequency to minimize the size of the components (for a buck converter, increasing the frequency reduces both the output inductor AND the output capacitor) and thus have less stored internal power reserves if subjected to sudden peak overload conditions.

The shunt resistor is typically integrated onto the same wafer die as the main controller IC and has a much tighter resistor value tolerance, giving less variation in the overcurrent limit.

cycle-by-cycle current limit monitor

DC/DC switching regulators should be dimensioned to handle the worst-case peak load conditions

Additionally, most switching regulator controllers also use a cycle-by-cycle current limit monitor based on a precise comparator output rather than relying on an imprecise Vbe junction threshold voltage.

As a result, they will shut down almost instantly if the overcurrent or short-circuit protection limit is reached. Therefore, DC/DC switching regulators should be dimensioned to handle the worst-case peak load conditions rather than the average load.

Conclusion

Over-specifying an AC/DC or DC/DC converter to cope with transient peak loads as if they were a continuous condition is inefficient and may lead to a larger power supply than is necessary.

By understanding the average, worst-case, and peak load conditions of the application, an optimum solution can be chosen that ensures a reliable supply voltage at a lower cost. The technical support engineers or technical sales team can advise on the best solution for the application.