Effective maintenance of complex industrial processes is vital to keep productivity up and costs down. Condition-Based Maintenance (CBM) is an alternative to regular maintenance scheduling that uses data from sensors in the Industrial Internet of Things to detect performance deterioration trends before a failure occurs.

This article discusses the subject and suggests suitable power supply modules for the sensor nodes.

little manual intervention

The developed world is moving towards higher and higher levels of industrial automation, enabling more manufacturing output at lower costs with increased flexibility. Similarly, data centers, distribution warehouses and infrastructure facilities have a goal to operate ‘lights out’ with little manual intervention to reduce labor expense.

Infrastructure facilities have a goal to operate ‘lights out’ with little manual intervention to reduce

‘Industry 4.0’ or IIoT, the Industrial Internet of Things is an integral part of this, with intelligence pushed out to the ‘edges’ of processes so that monitoring and control is close to where it is needed for rapid reaction times, with an overarching network of communication between the monitoring and sensing elements and a central control. This might be via ‘the cloud,’ through which data is aggregated, analyzed and used as inputs to control algorithms, to optimize processes in a so-called smart factory.

Life in mechanical components

The benefits of smart factories are wide-ranging, enabling low-cost products and services, while minimizing energy consumption. But what if something goes wrong? They’re not talking about the ‘rise of the machines’ here, just a simple mechanical breakage or a spurious junction failure in a processor due to a direct hit from a cosmic ray, or one of a myriad of other ‘chance’ failure modes.

System designers include tedium for critical system elements to cover single or even double failures

A high percentage of electrical infrastructure worldwide is greater than 25 years old, so increasing failure rates are a concern. Therefore, system designers include redundancy for critical system elements to cover single or even double failures, depending on the application and rate the components used with wide margins for a more reliable operation. However, ‘wear and tear’ is a fact of life in mechanical components and even in electronics, where capacitors dry out, surge limiters become compromised and semiconductors accumulate crystal lattice defects over time.

Maintenance is still needed

It is possible to just wait for a failure to occur and correct it at source, along the lines of “if it ain’t broke, don’t fix it”, but failures rarely occur at a convenient time. Such ‘corrective’ maintenance is clearly an attractive approach for non-critical functions, such as one blown LED in a lighting fixture group, or if they go back to the example of a multiply redundant system that is designed to be unaffected by single failures. They do have to know that the failure has occurred of course, so monitoring is key. A stock of parts and sufficient manpower, perhaps 24/7, must also be kept at the ready, ‘just in case’.

Functioning but old fuses might be traded out and surge arrestors and electrolytic capacitors replaced

For most processes, a better way to maintain production throughput has traditionally been to rely on periodic ‘preventive’ maintenance and inspection. For a simple mechanical system, it could be that filters would be replaced regularly, oil changed, bearings checked or clearances adjusted for wear, etc. In electronics, functioning but old fuses might be swapped out and surge arrestors and electrolytic capacitors replaced. Deciding when to do this is difficult, too late and disruptive failure is possible and too early, good parts are discarded and undue effort and cost is expended.

Timing is therefore a challenge, with scheduling of the work based on time elapsed, usage or just gut feeling and experience. High availability systems might typically have Failure Modes and Effects and Criticality Analysis (FMECA) performed, to put some science behind the predicted failure frequencies and their impact. Parts stockholding can be minimized however and maintenance personnel scheduled to do the work at convenient times.

Maintenance based on condition is the ideal

With large, complex processes, it is very difficult to set preventive maintenance schedules with sufficient accuracy, so an alternative is ‘CBM’ or Condition-Based Maintenance. This is the ideal, where parts are replaced or adjusted depending on their measured remaining lifetime.

This involves knowing the current condition of a part, even if it still performs perfectly, but has started its ‘wear-out’ phase. For example, an oil filter may allow sufficient lubricant flow today with only say, 10% filtering effect lost, but if you know that 50% is unacceptable and it will take 10 weeks to get to that state, you can schedule replacement in eight weeks. Similarly, a change in the vibration signature of a motor or machine can be analyzed in real-time to extrapolate when a bearing failure would occur.

This is the ideal, where parts are replaced or adjusted depending on their measured remaining lifetime

Parameters that can be monitored to detect changes and trends in performance are changes in fluid levels, vibration signatures, infrared thermography for contactless temperature measurement, oil opacity, current and voltage signatures in the electrical supplies, ultrasound leak detection, ozone sensors for arcing and corona discharge, and much more. If CBM is implemented in existing systems, the capital cost of adding this level of intensive monitoring could be a short-term barrier, but the long-term savings that can be made are decisive.

Fortunately, the implementation of IIoT Big Data for process scheduling and optimization also yields data that can be used for CBM analysis. Any specific extra sensor functionality that is required for CBM is relatively easily interfaced into the existing processor nodes at the process ‘edges’. CBM data by its nature is slow to change and adds negligible overhead to the computing and communications requirements of IIoT, either wired or wireless. The different maintenance regimes are represented in Figure 1.

|

| Figure 1: Maintenance regime effect on process performance and reliability. |

CBM needs reliable power at the sensors

Power for the remote sensors and their data interfaces may already be present at the IIoT nodes, from a wired DC supply, onboard batteries, local energy harvesting, or from AC/DC converters. The environment at the sensor, IIoT node, and its power supply can be harsh and variable, with high power surges whenever heavy machinery is started or stopped, so isolation for both DC and AC supplies is required.

Additionally, the monitoring must continue to work reliably while the process itself is degrading, with perhaps higher temperature and vibration levels and it would be self-defeating if the CBM hardware needed any regular maintenance itself or had limited life. Robustness is therefore vital and the power converter particularly must be highly efficient to minimize energy draw and heat stress resulting in a shortened lifetime.

Robustness is therefore vital and the power converter particularly must be highly efficient to minimize

An example of an isolated DC/DC converter with a high ambient temperature rating (140°C maximum) is the RxxCT(E)xx series from RECOM providing 0.5W or 1W at 5V or 3.3V output from a nominal 5V input, all in a low-profile SOIC-16 package. The output voltages are compatible with typical active sensors and microcontrollers or DSP front ends for data analysis. For isolated CANBusTM, MODBusTM or PROFIBusTM interface power, isolation is provided with a 5 kVac reinforced rating or optionally 3kVDC basic rating for less demanding applications.

RACM40 series cover requirements

If the available supply varies widely such as that from solar cells charging a battery, a regulated DC output is needed. A simple linear regulator would be too inefficient, quickly draining the battery. RECOM’s R-78Exx-1.0 is an ideal switching regulator module in this case, with up to 97% efficiency in solar-powered applications that are typically outdoor, or for monitoring of mobile equipment such as railway axle bearings.

The system requires 24V with a maximum load of 410mA per node, so board-mount AC/DCs

Small AC/DC converters are often a convenient solution for node power running off local AC mains, sometimes up to 277VAC nominal. These could be coupled with the upcoming IO-Link industrial sensor system, a digital bi-directional serial interface that uses a standard M12 connector.

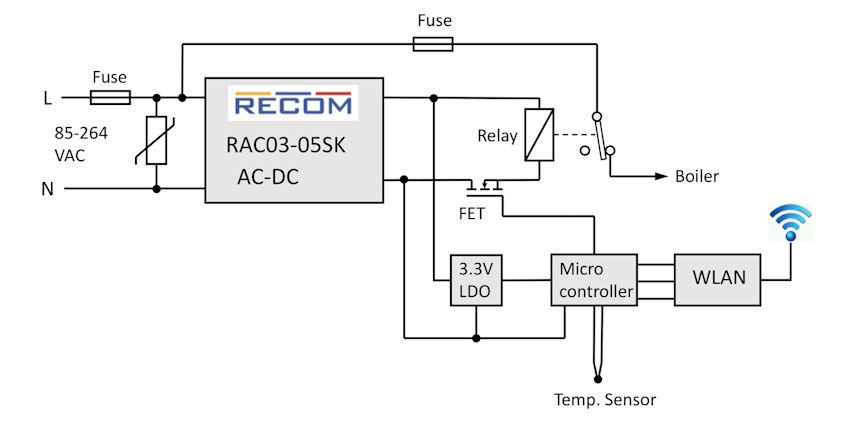

The system requires 24V with a maximum load of 410mA per node, so board-mount AC/DCs from RECOM in their RAC10, RAC20 and RACM40 series cover requirements up to 40W for quad IO-Link ports. The lower power RAC03 series could also be used in a process controller incorporating a wireless connection, to remote control a process and to signal out-of-specification temperature.

Power requirements

The example shown in Figure 2. can be manufactured in a volume that is only about 40x25x25 mm. The process feedback is not limited to just temperature; an acoustic noise, fluid flow or gas sensor could just as easily be incorporated.

|

| Figure 2: A small AC/DC converter powers a sensor, microcontroller and bidirectional wireless link. |

Often, gas leak, acoustic noise and IR temperature sensors are ceiling-mounted and suitable AC power is available from the lighting circuit, which can be 115V, 230V or 277VAC, the phase to neutral voltage in a 480V three-phase system. Data might be transmitted by long-range LPWAN radio (LoRa, sigfox, KNX-RF, etc.) or the cell network (5G, NB-IoT, GSM, etc). Power requirements are typically low so the universal input, 5W, board-mounted, RECOM RAC05-K/277 would be a good fit.

Products available from RECOM

For the ultimate in autonomy, some sensor nodes can be powered by harvested energy. This could be solar but also acoustic, RF, vibration, or temperature gradients. The voltage source can be very low, so efficient power conversion is needed to boost it up to typical sensor and processor voltages.

The RECOM REH-3-31.8 module is specifically designed for the job, operating down to 50mV input for a dual 3.3V/1.8V output. The part includes a Maximum Power Point (MPP) tracking function for PV cells and can be coupled with a battery or supercapacitor for energy storage.

Condition-based monitoring is the ideal way to maintain process availability at the lowest cost and is conveniently integrated with IIoT. Reliable and cost-effective power conversion is a vital element of CBM and the range of products available from RECOM comprehensively covers the application requirements.