This article explores the latest methods for fault detection that can be used to improve the reliability and safety of electrical systems. Electrical faults are caused by disturbances within a power system network and these disturbances can result in severe economic losses.

What is an electrical fault? An electrical fault is an abnormal condition within a power distribution system that results in improper system voltages and current flows. A fault in an electrical system can lead to extended outages, equipment damage, fires, and personnel injuries.

Common Types of Electrical Faults

A three-phase bolted fault is the least common fault type, but usually produces the highest fault currents

In a traditional three-phase power system, there are four major types of electrical faults that can be classified based on the number of phases involved. A three-phase bolted fault is when all three-phase conductors come in contact with no impedance between them.

A three-phase bolted fault is the least common fault type, but usually produces the highest fault currents. A phase-to-phase fault, or a bolted line-to-line fault, is a fault that occurs with zero impedance between two phases. Its fault current magnitude is approximately 87% of a three-phase bolted fault. The third type of fault is a phase-to-phase-to-ground fault, which involves two phases and ground. The fourth type of fault is a single-line-to-ground fault, which involves an individual phase and ground. A single-line-to-ground fault is the most frequently occurring type of fault.

Power distribution system

Electrical faults can occur in various locations within a power distribution system. This can include switching devices, manholes, handholes, pull-boxes, splices, or cable terminations. Electrical faults at these locations must be cleared as quickly as possible to eliminate hazards to personnel and limit the damage to equipment.

Once the fault is cleared, isolated, and repaired, the electrical system needs to be restored as quickly as possible to ensure the continuity of plant service to minimize economic losses.

System Protection Methodology for Electrical Faults

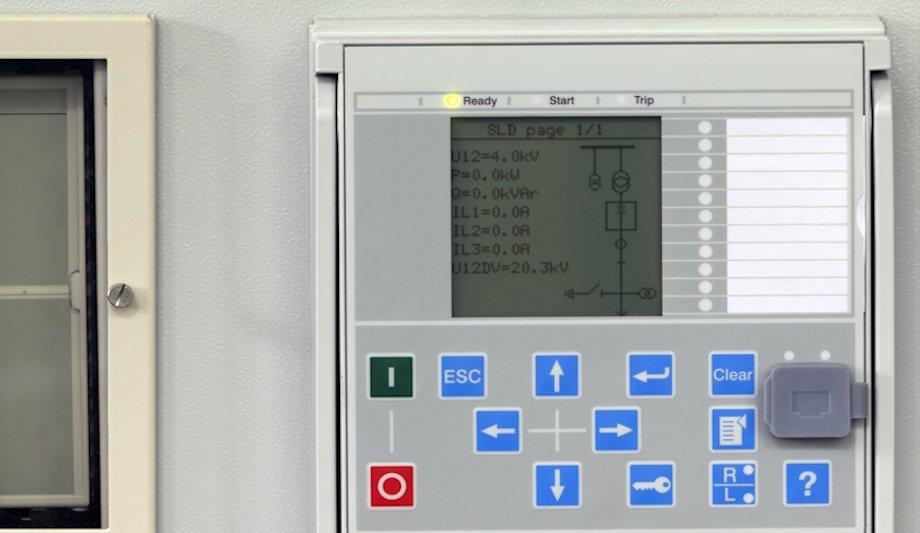

Traditionally, an electrical fault in a medium-voltage system is sensed by a protective relay

Traditionally, an electrical fault in a medium voltage system is sensed by a protective relay. Depending upon the magnitude and duration of the fault, the relay issues a signal to its corresponding circuit breaker to trip after a predetermined amount of time. The relay then asserts a flag to denote that a trip condition has occurred.

Once the relay trips the breaker and clears the fault, it is then up to qualified electrical personnel to determine the location and cause of the fault in order to perform maintenance activities to correct it. Older protective relays cannot diagnose the fault condition, while newer relays can distinguish between fault types and even locate the fault.

Different types of faults

To understand how the type of fault can be determined, an understanding of symmetrical components is required. Any fault can be broken down into positive sequence, negative sequence, and zero sequence components. A bolted three-phase fault is considered as being a balanced fault, and in terms of sequence components, it consists entirely of the positive sequence.

A phase-to-phase fault contains positive and negative sequence components. Single or double phase to ground faults will contain all three sequence components. Below are phasor representations for the four different types of faults and an illustration of their symmetrical components.

Advanced Methods for Identifying and Locating Faults

A modern protective relay can measure and analyze the positive, negative, and zero sequence components. When configured properly, these relays monitor the phase current magnitudes, angles, and convert these quantities into their sequence components to determine the type of fault.

Additionally, these protective relays can be programmed with the known line impedance, which can then be used to determine the effective distance between the relay and the fault. This is performed on the basis of the known line impedance and the fault impedance’s sequence components.

Advanced fault location techniques

These parameters can be programmed and configured into the protective relay

When an accurate short circuit study has been performed for a given electrical system, the equivalent Thevenin impedance elements of a cable segment are known. These parameters can be programmed and configured into the protective relay. If an electrical fault were to occur, the relay could determine the fault impedance, which in turn, can be compared against the per-unit line impedance.

The analysis and comparison of these two values can be used for fault locating (i.e., determining the distance from the breaker). On a campus distribution feeder that can stretch thousands of feet, such advanced fault location techniques will expedite restoration to save significant time and money.

Advanced techniques for fault detection

Locating a fault is essential part of quickly addressing an issue to restore service as quickly as possible. By establishing capabilities for identifying both the fault type and the fault location, they help the customers save time and money by being able to help pinpoint where troubleshooting is required before dispatching qualified personnel to implement corrective action.

Utilizing an electrical engineering firm that understands advanced techniques for fault detection and location is vital to enhancing the electrical system. This includes reduced outage durations, reduced equipment damage, and improved personnel safety.